Acoustically transparent membrane module with high resistance to water pressure and manufacture method thereof

A manufacturing method and water pressure-resistant technology, applied in diaphragm structure, chemical instruments and methods, electrical components, etc., can solve problems such as low water pressure resistance, sound-permeable membranes that cannot meet the trend-leading development of consumer electronics, and achieve water pressure resistance values Large, undistorted audio characteristics, clear and undistorted sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

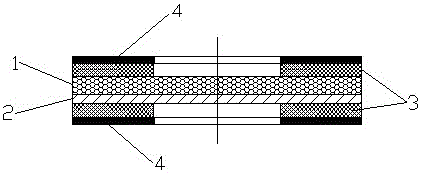

[0031] A high water pressure-resistant sound-transmitting membrane assembly, comprising: a high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene coating film, a pressure-sensitive adhesive tape 3 and a release paper 4, and the high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene The tetrafluoroethylene coating film comprises a microporous foamed polyurethane resin coating 1 and a hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2, one side of the described hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2 Microporous foamed polyurethane resin coating 1 is coated on the upper surface, release paper 4 is provided on the outer surface of pressure-sensitive adhesive tape 3, and the front surface of pressure-sensitive adhesive tape 3 and expanded polytetrafluoroethylene coating film with high water pressure resistance and sound transmission The reverse side is laminated at the same ...

Embodiment 2

[0039] A high water pressure-resistant sound-transmitting membrane assembly, comprising: a high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene coating film, a pressure-sensitive adhesive tape 3 and a release paper 4, and the high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene The tetrafluoroethylene coating film comprises a microporous foamed polyurethane resin coating 1 and a hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2, one side of the described hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2 Microporous foamed polyurethane resin coating 1 is coated on the upper surface, release paper 4 is provided on the outer surface of pressure-sensitive adhesive tape 3, and the front surface of pressure-sensitive adhesive tape 3 and expanded polytetrafluoroethylene coating film with high water pressure resistance and sound transmission The reverse side is laminated at the same ...

Embodiment 3

[0047] A high water pressure-resistant sound-transmitting membrane assembly, comprising: a high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene coating film, a pressure-sensitive adhesive tape 3 and a release paper 4, and the high water-pressure-resistant sound-transmitting expanded polytetrafluoroethylene The tetrafluoroethylene coating film comprises a microporous foamed polyurethane resin coating 1 and a hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2, one side of the described hydrophobic and oleophobic expanded polytetrafluoroethylene film layer 2 Microporous foamed polyurethane resin coating 1 is coated on the upper surface, release paper 4 is provided on the outer surface of pressure-sensitive adhesive tape 3, and the front surface of pressure-sensitive adhesive tape 3 and expanded polytetrafluoroethylene coating film with high water pressure resistance and sound transmission The reverse side is laminated at the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com