Aluminum alloy degreasing and polishing two-in-one treatment solution and method for degreasing and polishing aluminum alloy

An aluminum alloy and treatment liquid technology, applied in the field of aluminum alloy degreasing and polishing two-in-one treatment liquid, can solve the problems of weight reduction of aluminum alloy profiles, loss of aluminum alloy profiles, etc., so as to improve corrosion resistance, reduce weight, and ensure brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

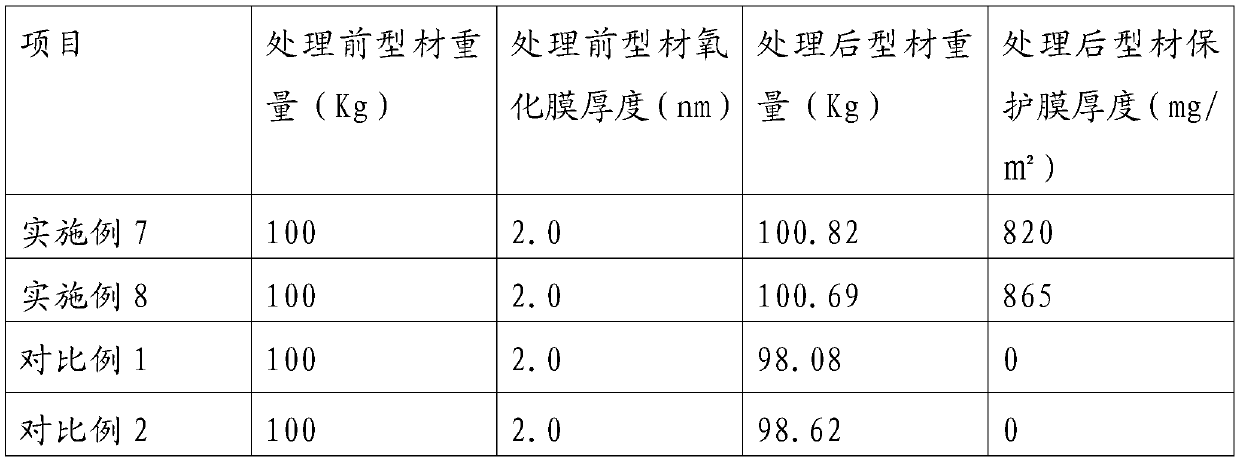

Examples

Embodiment 1

[0023] A two-in-one treatment solution for aluminum alloy degreasing and polishing, comprising the following components: oxalic acid 10g / L, ammonium bifluoride 2g / L, surfactant alkylphenol polyoxyethylene ether 0.005g / L and auxiliary agent nitrous acid Sodium 0.10g / L.

Embodiment 2

[0025] A two-in-one treatment solution for aluminum alloy degreasing and polishing, comprising the following components: oxalic acid 5g / L, hydrofluoric acid 2.5g / L, surfactant octylphenol polyoxyethylene ether 0.008g / L and additives Ammonium nitrite 0.009g / L.

Embodiment 3

[0027] A two-in-one treatment solution for aluminum alloy degreasing and polishing, comprising the following components: oxalic acid 12g / L, ammonium bifluoride 1.5g / L, surfactant nonylphenol polyoxyethylene ether 0.01g / L and auxiliary agent hydrogen peroxide 0.12g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com