Foam concrete

The technology of foam concrete and foam stabilizer is applied in the field of foam concrete to achieve the effects of good plasticity, reduced hydrothermalization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

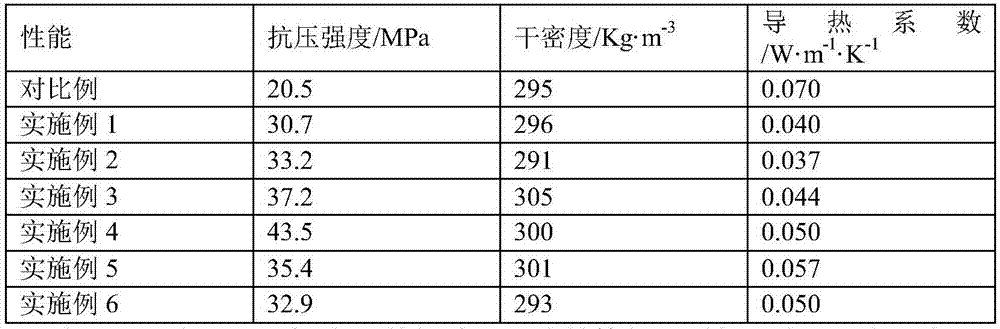

Examples

Embodiment 1

[0049] In the mixing station, first add 285g of cement, 1.8g of polypropylene fiber, 15g of superfine slag powder, and 153g of water to stir in parts by mass, then add 1.2g of polycarboxylic acid superplasticizer, 5.1g of sodium chloride, and calcium chloride 2.1g and stir, and finally add 16g of hydrogen peroxide and stir evenly to obtain Experimental Sample 1.

Embodiment 2

[0051] In the mixing station, first add 270g of cement, 1.8g of polypropylene fiber, 30g of superfine slag powder, and 150g of water to stir in parts by mass, then add 1.2g of polycarboxylate superplasticizer, 5.1g of sodium chloride, and calcium chloride 2.1g was stirred, and finally 16g of hydrogen peroxide was added and stirred evenly to obtain Experimental Sample 2.

Embodiment 3

[0053] In the mixing station, first add 255g of cement, 1.8g of polypropylene fiber, 45g of superfine slag powder, and 147g of water to stir in parts by mass, then add 1.2g of polycarboxylate superplasticizer, 5.3g of sodium sulfate, and 2.3g of calcium sulfate Stir, and finally add 16g of hydrogen peroxide and stir evenly to obtain Experimental Sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com