Fire-resistant heat-insulated and energy-saving glazed tile

A technology for thermal insulation and glazed tiles, applied in the field of building materials, can solve problems such as physical health injury, poor thermal insulation of glazed tiles, large wall thickness and weight, and achieve the effects of reducing land occupation, enhancing acid resistance, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

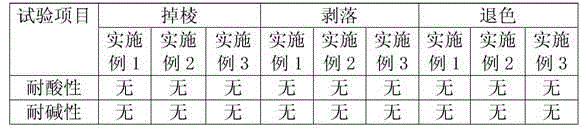

Examples

Embodiment 1

[0026] A fire-resistant, heat-insulating, heat-preserving and energy-saving glazed tile, the composition of raw materials (by weight, each part is 1 kg) includes:

[0027] Ceramic blank: 12 parts of attapulgite clay tailings powder, 16 parts of coal gangue, 37 parts of kaolin, 15 parts of expanded vermiculite, 6 parts of cement, 10 parts of shale powder, 6 parts of gypsum powder, 5 parts of alumina, alum 2 parts, 0.2 parts of zirconium silicate;

[0028] Bottom glaze: 6 parts of gypsum powder, 8 parts of diatomite, 14 parts of kaolin, 15 parts of quartz, 10 parts of potassium feldspar, 6 parts of alumina, 3 parts of zinc oxide, 3 parts of calcium oxide, 6 parts of borax, hexametaphosphoric acid 0.1 part of sodium, 0.1 part of silicone resin, 0.5 part of titanium oxide, 0.2 part of cerium oxide, 0.2 part of iron oxide, 0.2 part of stannous chloride;

[0029] Surface glaze: 0.2 parts of sodium fluorosilicate, 0.2 parts of sodium polyacrylate, 0.2 parts of sodium hexametaphospha...

Embodiment 2

[0031] A fire-resistant, heat-insulating, heat-preserving and energy-saving glazed tile, the composition of raw materials (by weight, each part is 1 kg) includes:

[0032] Ceramic blank: 16 parts of attapulgite clay tailings powder, 12 parts of coal gangue, 42 parts of kaolin, 10 parts of expanded vermiculite, 10 parts of cement, 6 parts of shale powder, 10 parts of gypsum powder, 2 parts of alumina, alum 5 parts, 1 part of zirconium silicate;

[0033] Bottom glaze: 8 parts of gypsum powder, 12 parts of diatomite, 16 parts of kaolin, 20 parts of quartz, 15 parts of potassium feldspar, 8 parts of alumina, 5 parts of zinc oxide, 5 parts of calcium oxide, 10 parts of borax, hexametaphosphoric acid 0.5 parts of sodium, 0.8 parts of silicone resin, 1.5 parts of titanium oxide, 0.8 parts of cerium oxide, 0.8 parts of iron oxide, and 0.8 parts of stannous chloride;

[0034] Surface glaze: 0.8 parts of sodium fluorosilicate, 0.6 parts of sodium polyacrylate, 0.6 parts of sodium hexam...

Embodiment 3

[0036] A fire-resistant, heat-insulating, heat-preserving and energy-saving glazed tile, the composition of raw materials (by weight, each part is 1 kg) includes:

[0037] Ceramic blank: 14 parts of attapulgite clay tailings powder, 14 parts of coal gangue, 40 parts of kaolin, 12 parts of expanded vermiculite, 8 parts of cement, 8 parts of shale powder, 8 parts of gypsum powder, 3 parts of alumina, alum 4 parts, 0.5 parts of zirconium silicate;

[0038] Bottom glaze: 7 parts of gypsum powder, 10 parts of diatomite, 15 parts of kaolin, 18 parts of quartz, 12 parts of potassium feldspar, 7 parts of alumina, 4 parts of zinc oxide, 4 parts of calcium oxide, 8 parts of borax, hexametaphosphoric acid 0.3 parts of sodium, 0.4 parts of silicone resin, 0.8 parts of titanium oxide, 0.5 parts of cerium oxide, 0.8 parts of iron oxide, 0.6 parts of stannous chloride;

[0039] Surface glaze: 0.4 parts of sodium fluorosilicate, 0.4 parts of sodium polyacrylate, 0.4 parts of sodium hexametap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com