High corrosion resistance reinforced concrete corrosion inhibitor

A technology of reinforced concrete and rust inhibitor, which is applied in the field of steel rust inhibitor, and can solve the problems of small adsorption force and insufficient binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: a kind of high anti-corrosion reinforced concrete anticorrosion agent, the optimal combination weight percentage of each composition is

[0015] Sodium molybdate 0.08%, sodium dodecylsulfonate 0.12%, thiourea 0.3%, cerium nitrate 0.04%, and the rest is water.

[0016] All components are soluble in water. When mixing and making concrete, add them to the mixer according to the order of adding raw materials, but when adding water, add each rust inhibitor component into water to dissolve according to the requirements in the formula.

Embodiment 2

[0017] Embodiment 2: a kind of high anti-corrosion reinforced concrete anticorrosion agent, the optimal combination weight percentage of each composition is

[0018] Sodium molybdate 0.06%, sodium dodecylsulfonate 0.03%, thiourea 0.45%, cerium nitrate 0.12%, and the rest is water.

[0019] All components are soluble in water. When mixing and making concrete, add them to the mixer according to the order of adding raw materials, but when adding water, add each rust inhibitor component into water to dissolve according to the requirements in the formula.

Embodiment 3

[0020] Embodiment 3: a kind of high anti-corrosion reinforced concrete anticorrosion agent, the optimal combination weight percentage of each composition is

[0021] Sodium molybdate 0.10%, sodium dodecylsulfonate 0.12%, thiourea 0.45%, cerium nitrate 0.12%, and the rest is water.

[0022] All components are soluble in water. When mixing and making concrete, add them to the mixer according to the order of adding raw materials, but when adding water, add each rust inhibitor component into water to dissolve according to the requirements in the formula.

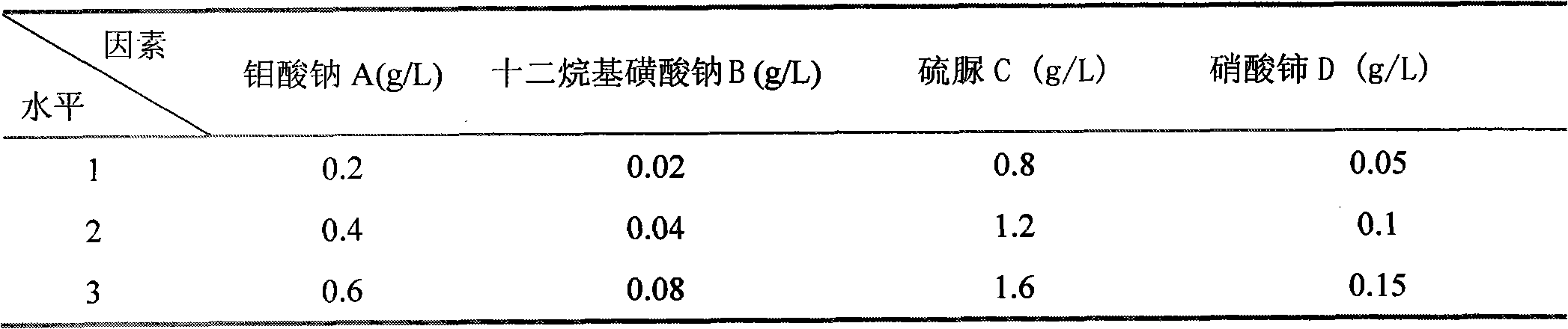

[0023] The present invention adopts four-factor three-level orthogonal test formula, selects four-factor three-level orthogonal test. The tables are as follows. Table 1 shows the rust-inhibiting components of the four factors, and their respective three addition levels.

[0024] Table 1 Factor level table

[0025]

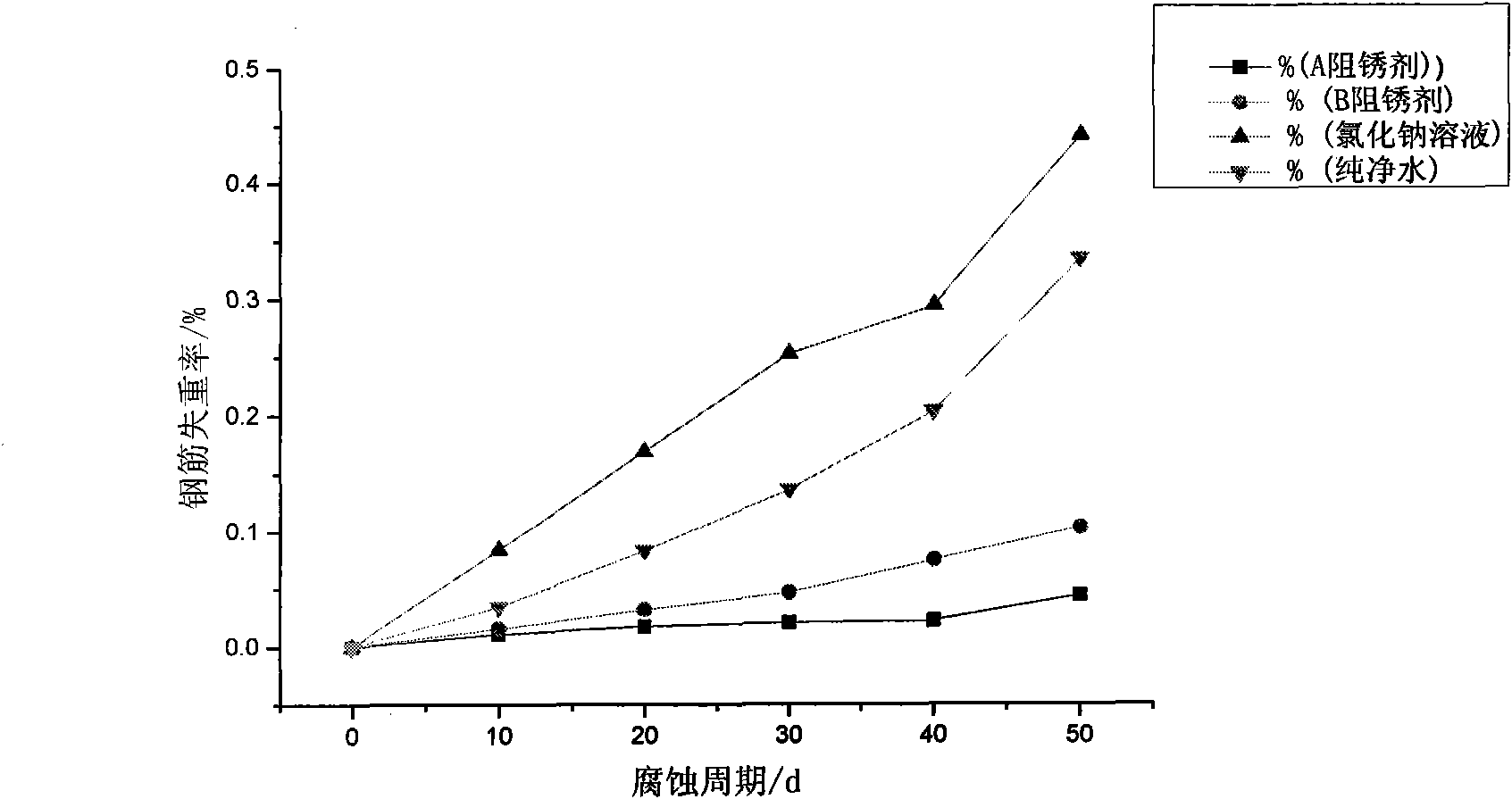

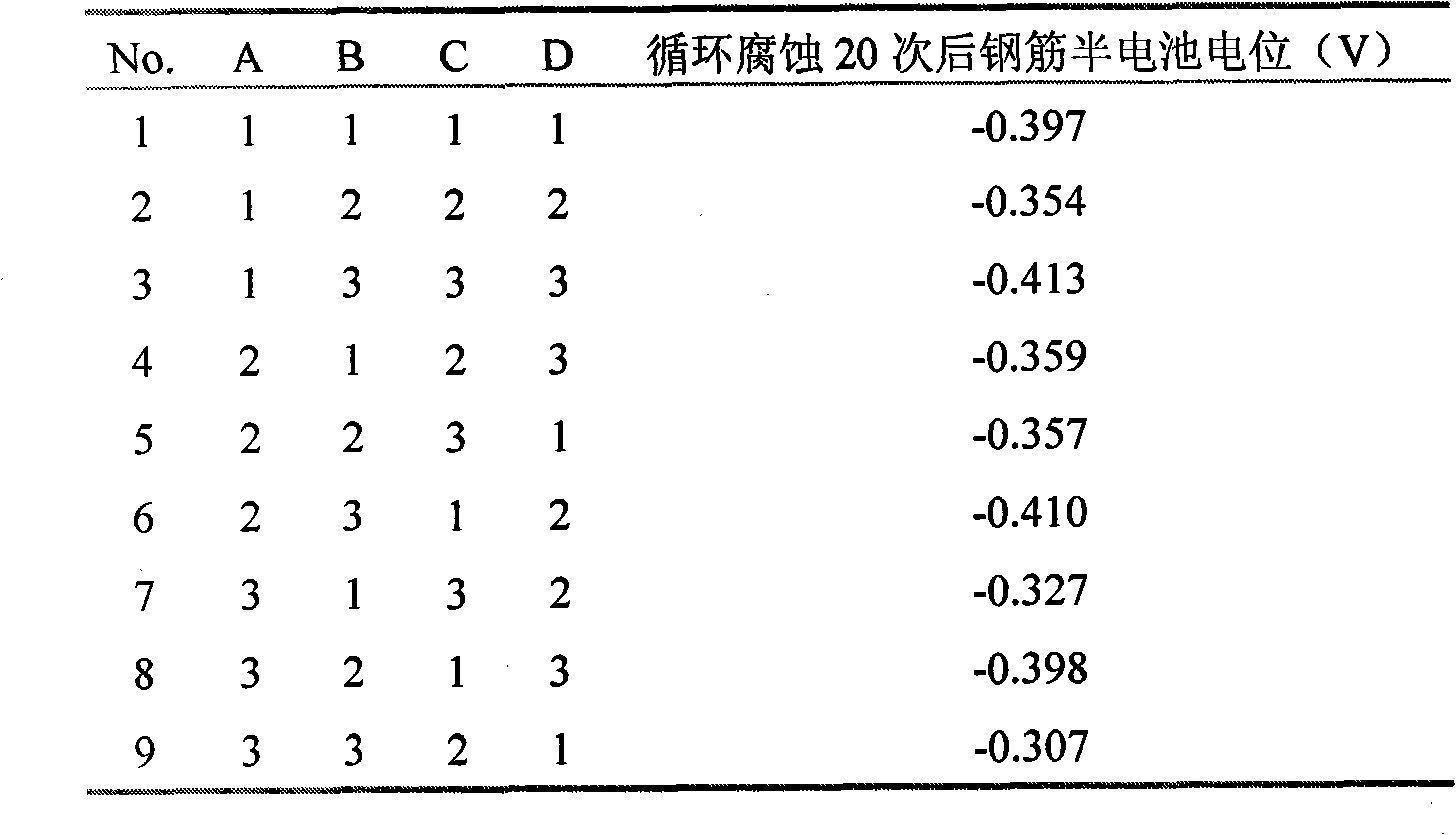

[0026] The left side of Table 2 reflects the design of the four-factor three-level orthogonal experiment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com