Easy turning glass fibre reinforced plastic groove cultivating method for Chinese yam

A fiberglass and yam technology, applied in container cultivation, botany equipment and methods, horticulture, etc., can solve problems such as difficult planting and harvesting of yams, and achieve the effects of saving labor and working hours, improving quality and soft soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

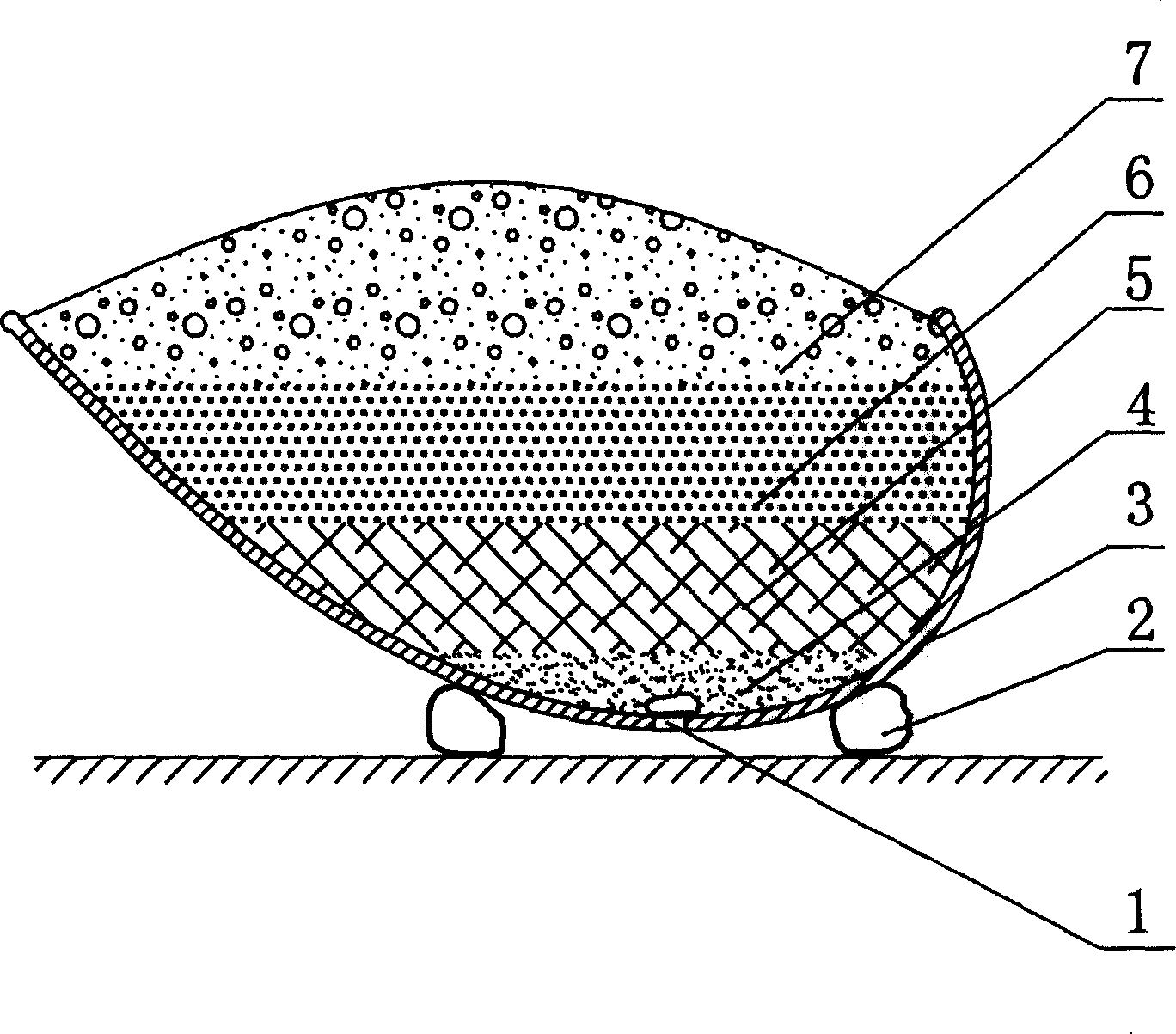

[0014] The production dimensions of the FRP tank are respectively taken as length 1.5m, width 40cm, depth 40cm, and thickness 3mm. The section of the groove is a volute shape with a radius of curvature of 30cm at the bottom and a radius of curvature of 50cm and 20cm on both sides. The segment surface becomes a smooth transition. A water-permeable hole with a diameter of 2 cm is opened at the bottom of both ends of the trough, and a small stone piece is placed on each hole. After placing the trough in a proper position, use a stone to support the outer sides of the trough bottom to fix the trough body. Spread fine sand with a thickness of 6 cm and a particle size of less than 30 mesh on the bottom of the trough, and then put orange stems, bottom fertilizer and soil into the trough in turn until the soil above the trough is curved like a bun. In the third month of the lunar calendar, plant yam reed heads at both ends of the trough, plant 4 heads on each end, and plant a sweet potato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com