Shearing mechanism

A technology of shearing mechanism and lower cutter, applied in metal processing and other directions, can solve problems such as low production efficiency and affect the use of mobile phones, and achieve the effect of improving production efficiency, improving product integrity, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

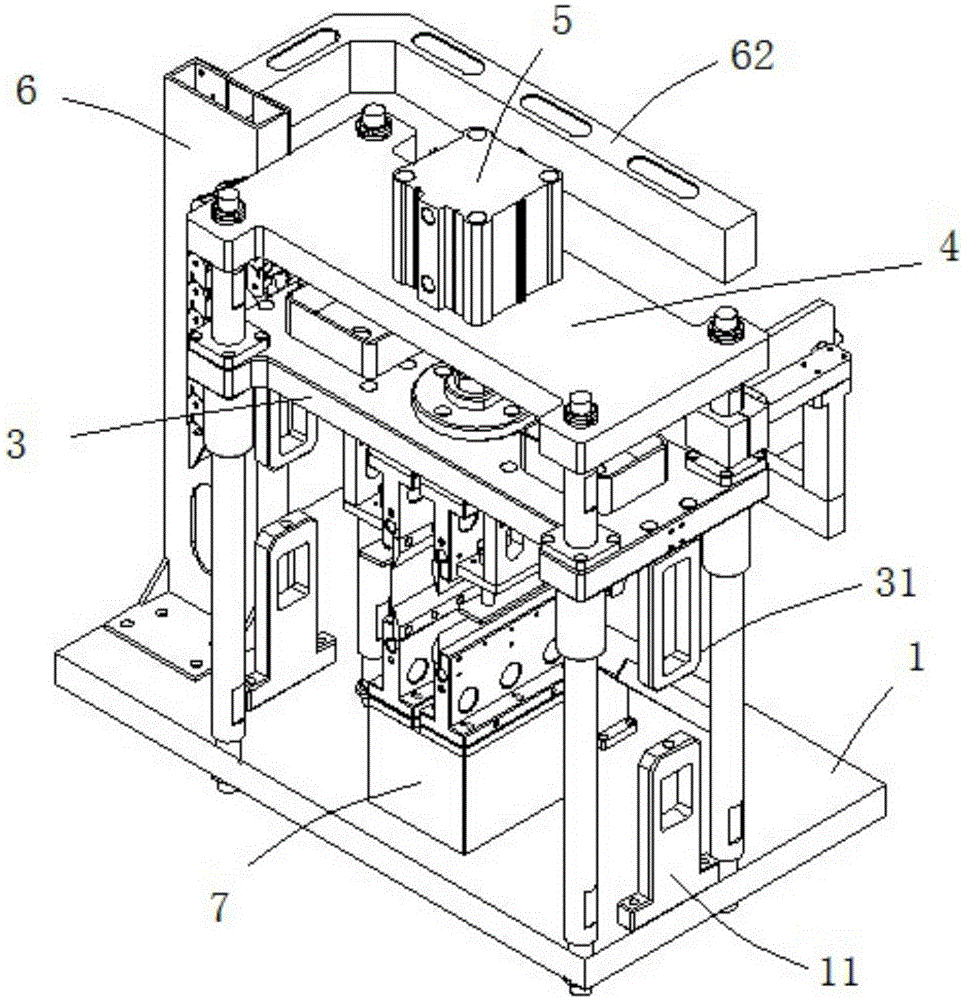

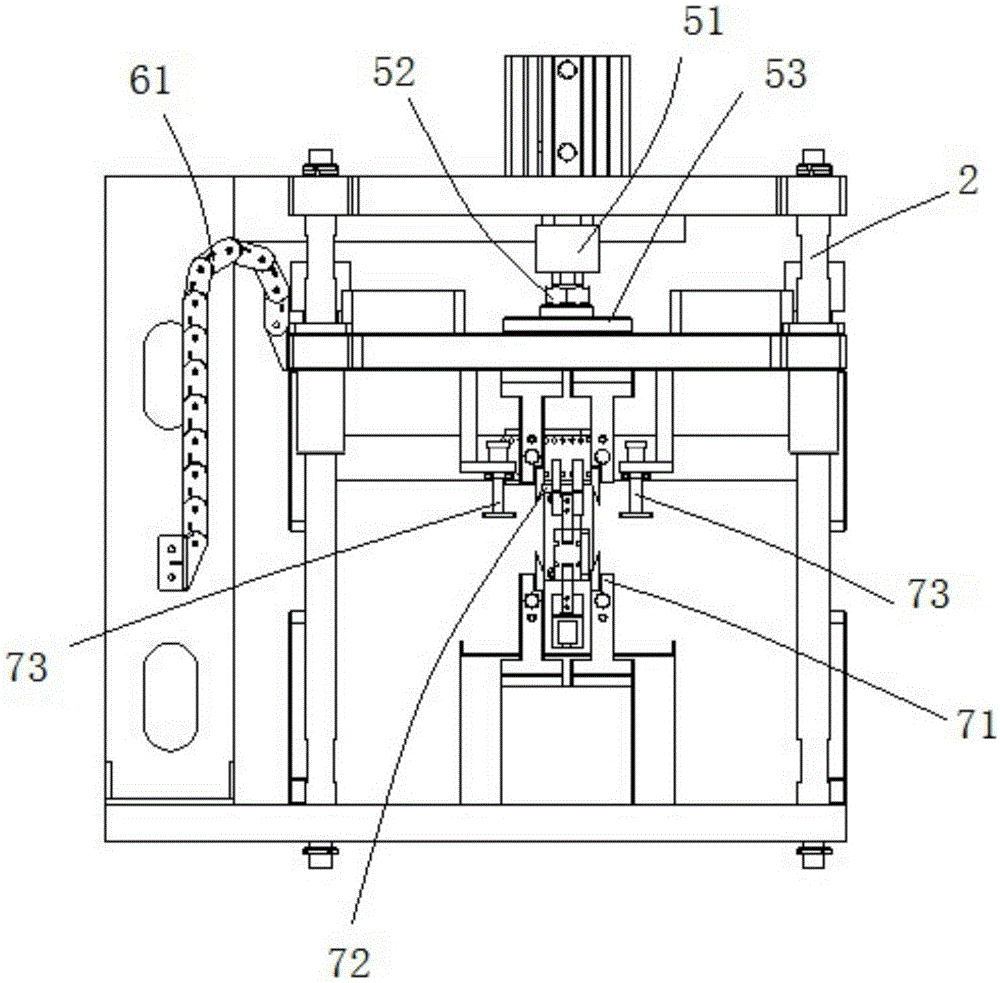

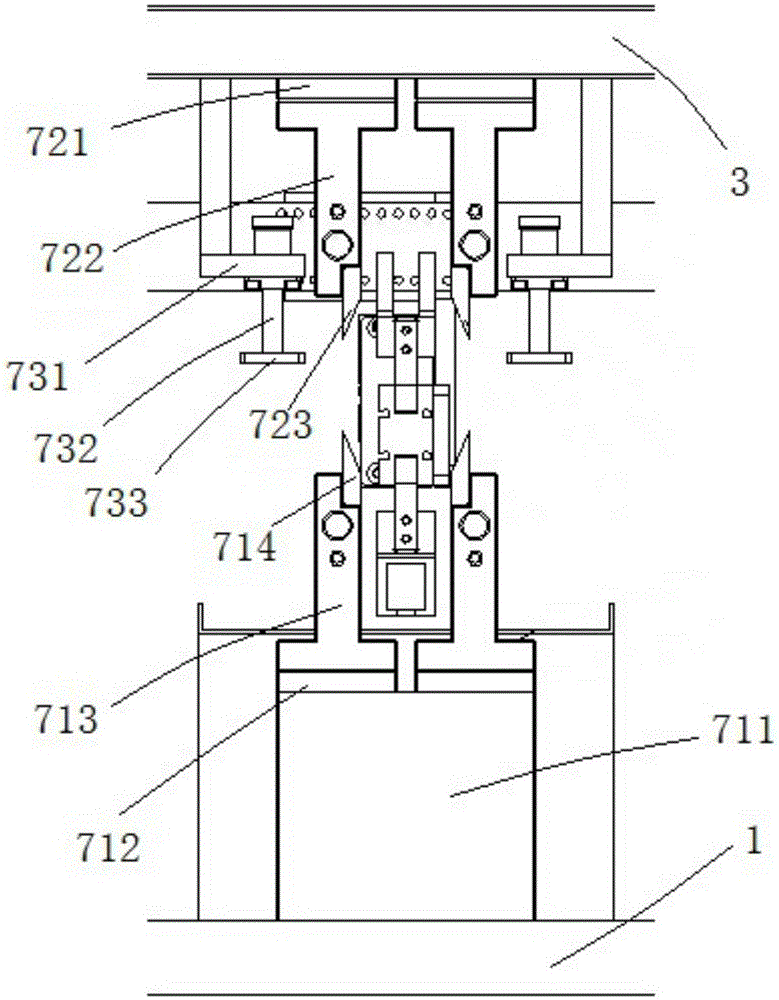

[0020] see Figure 1 to Figure 4 , the shearing mechanism of the present invention includes a base 1, and the base 1 is provided with four guide posts 2 distributed along the apexes of a rectangle, and the guide post 2 is provided with a top plate 4 and a movable plate 3, and the movable plate 3 is located at Between the base 1 and the top plate 4, the top plate 4 is provided with a cylinder 5, and the cylinder 5 drives the movable plate 3 to move along the guide column 2, and between the base 1 and the movable plate 3 A shearing module 7 is provided, and the shearing module 7 includes an upper cutter assembly 71 and a lower cutter assembly 72, the upper cutter assembly 71 is installed on the bottom surface of the movable plate 3, and the lower cutter assembly 72 Installed on the top surface of the base 1 , both sides of the upper cutter assembly 71 are provided with a positioning assembly 73 .

[0021] The upper cutter assembly 72 includes two upper knife seat connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com