PM trapper failure detection system

A fault detection, trap technology, applied in membrane filters, machines/engines, chemical instruments and methods, etc., can solve problems such as difficult PM traps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

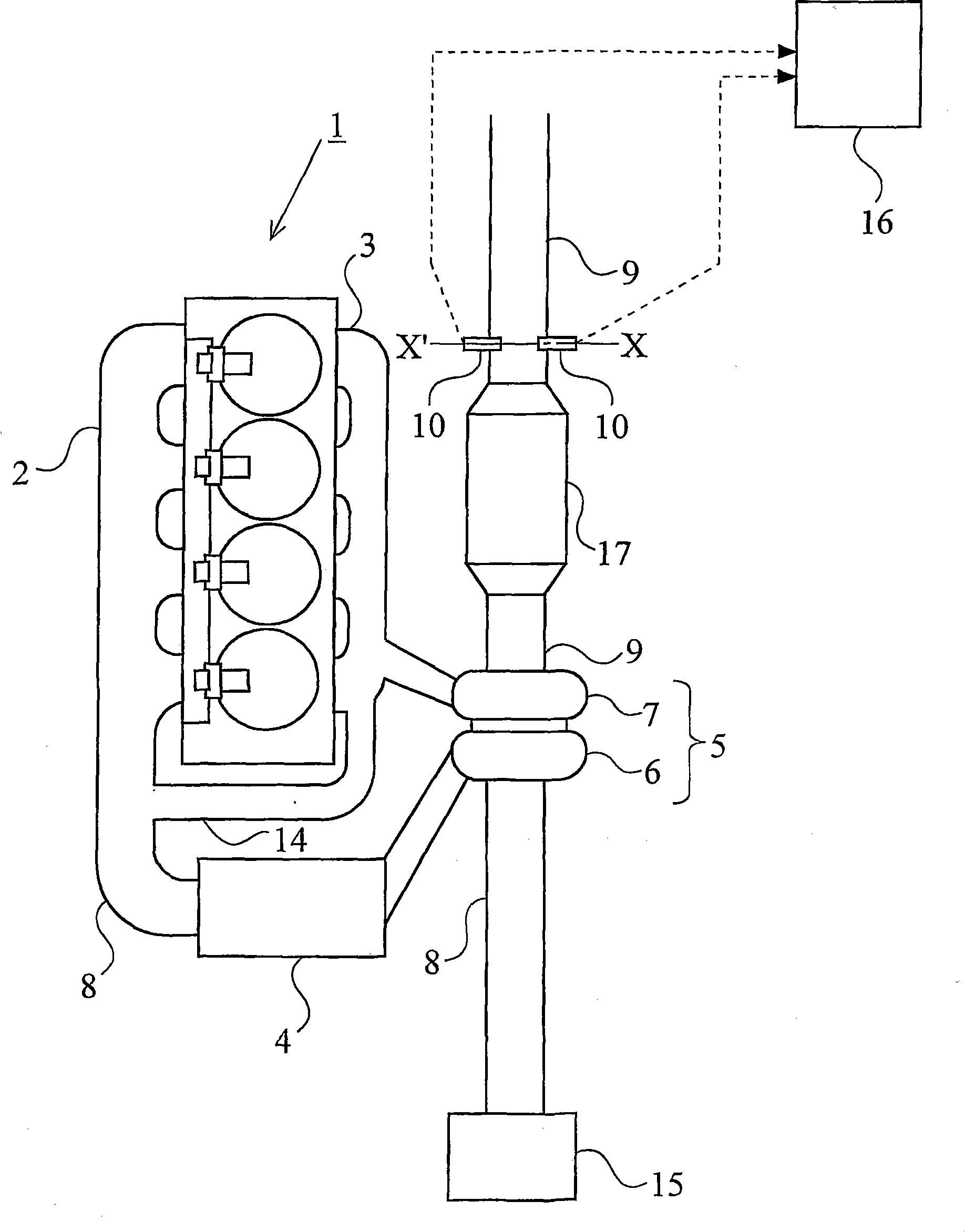

[0063] figure 1 It is a diagram showing a schematic configuration of an intake system and an exhaust system of an internal combustion engine to which the PM trap failure detection system of the present invention is applied.

[0064] figure 1 The internal combustion engine 1 shown is a water-cooled four-stroke diesel engine with four cylinders.

[0065] On the internal combustion engine 1, an intake manifold 2 is connected, and each branch pipe of the intake manifold 2 communicates with the combustion chamber of each cylinder through the intake port. An intake passage 8 is connected to the intake manifold 2 . An intercooler 4 that performs heat exchange between intake air and outside air is provided in the middle of the intake passage 8 . Upstream of the intercooler 4 is provided a compressor housing 6 of a turbocharger 5 that operates using exhaust gas energy as a drive source. Upstream of the compressor housing 6, an air filter 15 is provided.

[0066] An exhaust manifol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com