Steering cable saddle for large-tonnage cable crane

A cable crane and large-tonnage technology, applied in the direction of cable cranes, cranes, erection/assembly of bridges, etc., can solve problems such as high cost, large unbalanced horizontal force, and multiple wind cable configurations, and achieve cost savings and clear and reasonable force. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

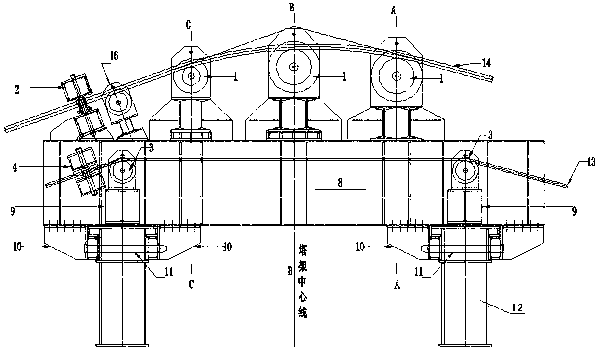

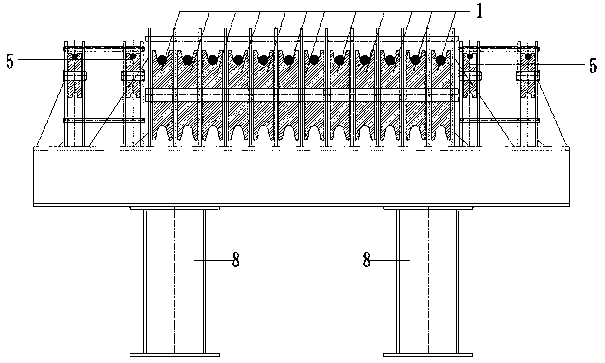

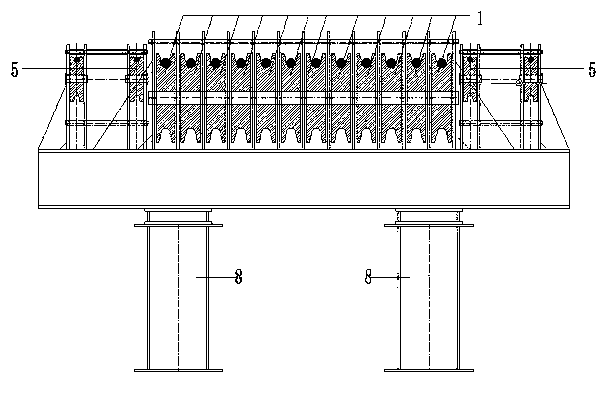

[0040] A large tonnage cable crane steering saddle, such as Figure 1~4As shown, it includes load-bearing cable axle assembly 1, load-bearing cable steering device 2, hoisting cable axle assembly 3, hoisting cable steering device 4, traction cable axle assembly 5, traction cable steering device 6, traversing axle assembly 7, and cable saddle Base distribution beam 8, cable saddle base connecting beam 9, slip limit block 10, pin shaft 11, cable saddle traverse T-shaped slideway beam 12, hoisting cable 13, load-bearing cable 14, traction cable 15 and traction cable transition Pulley 16.

[0041] On the distribution beam 8 of the cable saddle base, a load-bearing cable axle assembly 1, a load-bearing cable steering device 2, a hoisting cable steering device 4, a traction cable axle assembly 5, a traction cable steering device 6, and a traverse axle assembly 7 are arranged. The hoisting cable axle assembly is arranged on the connecting crossbeam 9, and is connected into a whole b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com