Preparation method of composite reinforced regenerated concrete with regenerated fiber and active minerals

A technology of recycled concrete and recycled fiber, which is applied in the direction of solid waste management, climate sustainability, and sustainable waste treatment. It can solve the problems of polymer elastic materials encroaching on land resources and the environment, and achieve improved mechanical properties. The method is simple and The effect of enhancing crack resistance and toughness resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

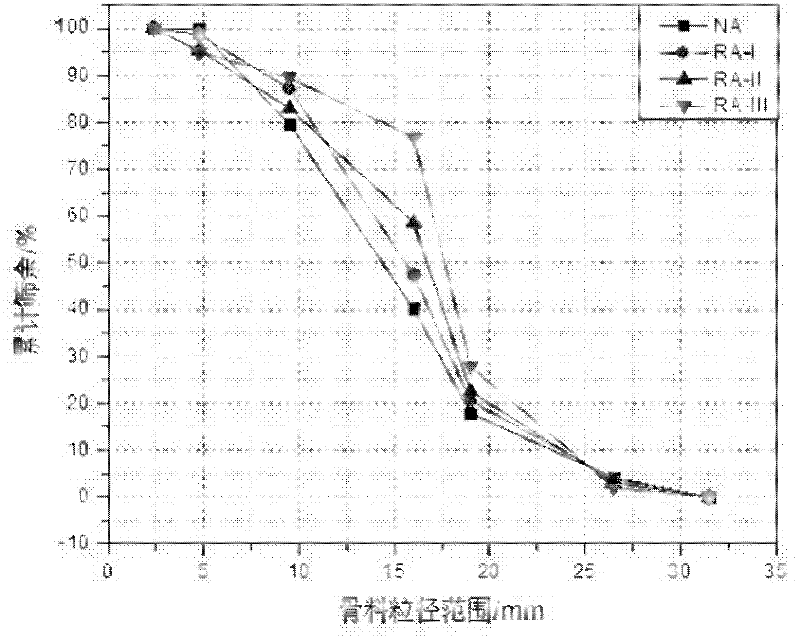

[0031] 1. Carry out mechanical crushing, screening, cleaning, etc. on waste concrete, and the particle gradation of the prepared coarse aggregate should meet the table in Article 3.2.1 of "Standards for the Quality and Testing Methods of Sand and Stone for Ordinary Concrete" (JGJ52-2006). 3.2.1-2 (grain grading range of crushed stone or pebble) Requirements for aggregate. Depend on figure 1 It can be seen that natural coarse aggregate NA, recycled coarse aggregate RA-I, RA-II, and RA-III all meet the requirements of JGJ52-2006 for continuous gradation of coarse aggregate.

[0032] Cumulative curve of particle size distribution figure 1 Determine the relevant particle size d of the particles 10 、d 30 and d 60 , and find the non-uniformity coefficient and coefficient of curvature Where d10 is the corresponding particle size when the mass percentage of particles smaller than a certain particle size is 10%; d 30 d60 is the corresponding particle size when the cumulative m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com