Color asphalt ultrathin wearing layer and preparation method thereof

A technology of colored asphalt and wear layer, applied in the field of highway pavement construction, can solve problems such as easy falling off and rolling, and achieve the effect of reducing thickness, low cost and improving driving conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The colored asphalt ultra-thin wear layer of the present invention is prepared from the following raw materials in parts by weight:

[0025] 5-10mm gravel: 34 to 36 parts;

[0026] Stone chips with particle size less than 3mm: 11 to 13 parts;

[0027] Mineral powder or cement: 0.8 to 1.2 parts;

[0028] Colored asphalt: 2 to 3 parts;

[0029] Polymer modified emulsified asphalt: 1.1 to 1.4 parts.

[0030] The specific technical requirements and preparation methods are as follows:

[0031] 1. Material index requirements

[0032] The raw material of colored asphalt ultra-thin wear layer is composed of 5-10mm crushed stone as coarse aggregate, stone chips with a particle size of less than 3mm as fine aggregate, mineral powder or cement as filler, polymer modified emulsified asphalt, and colored asphalt. The specific materials The indicator requirements are as follows:

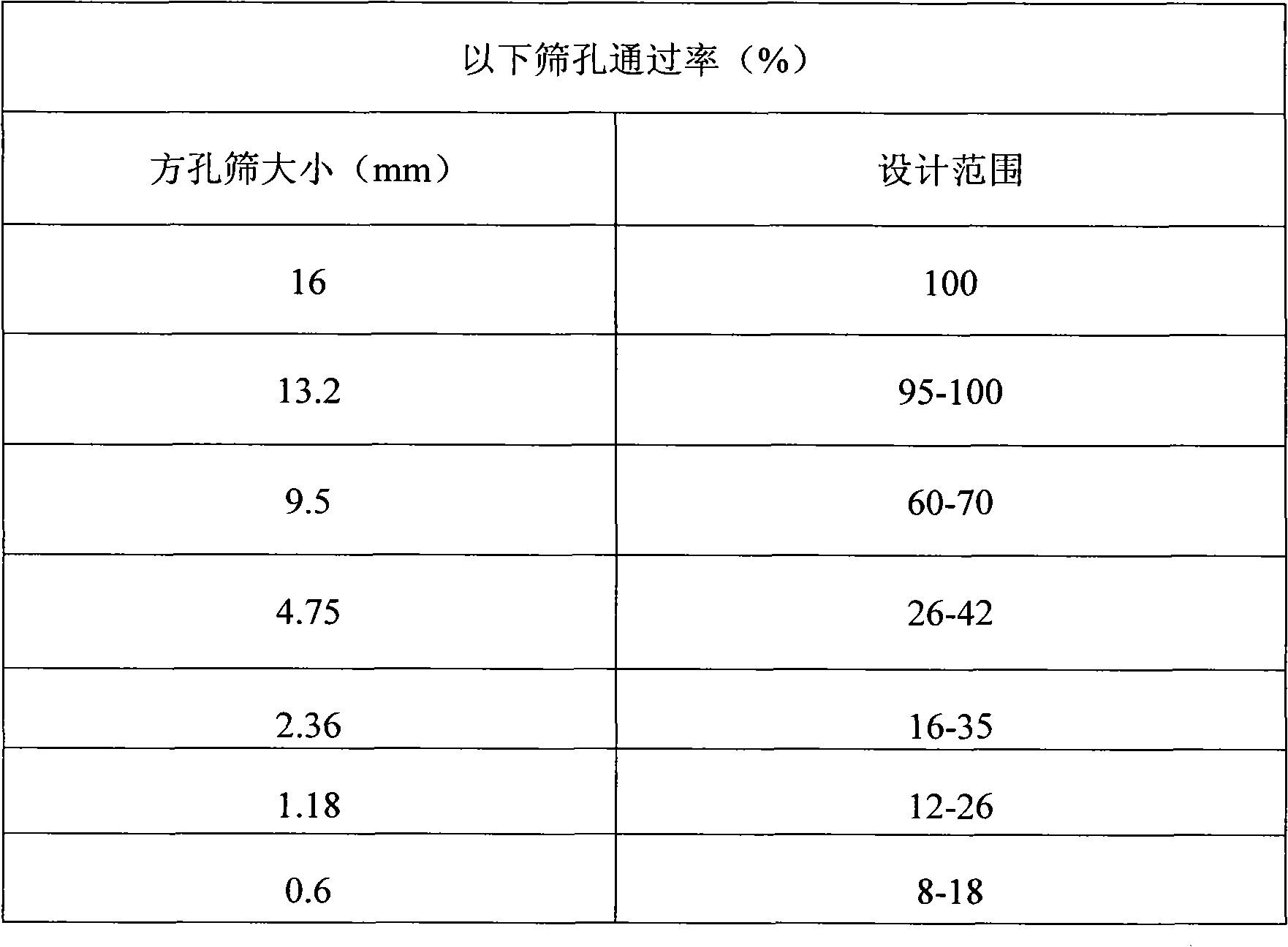

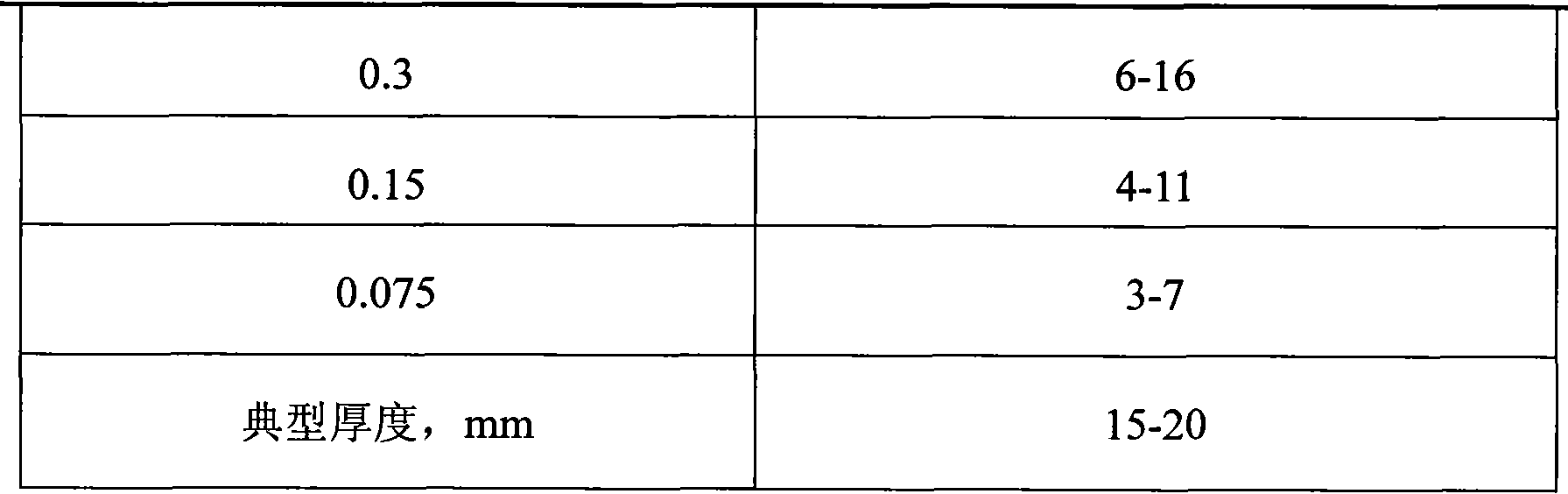

[0033] 1. Aggregate Grading Requirements

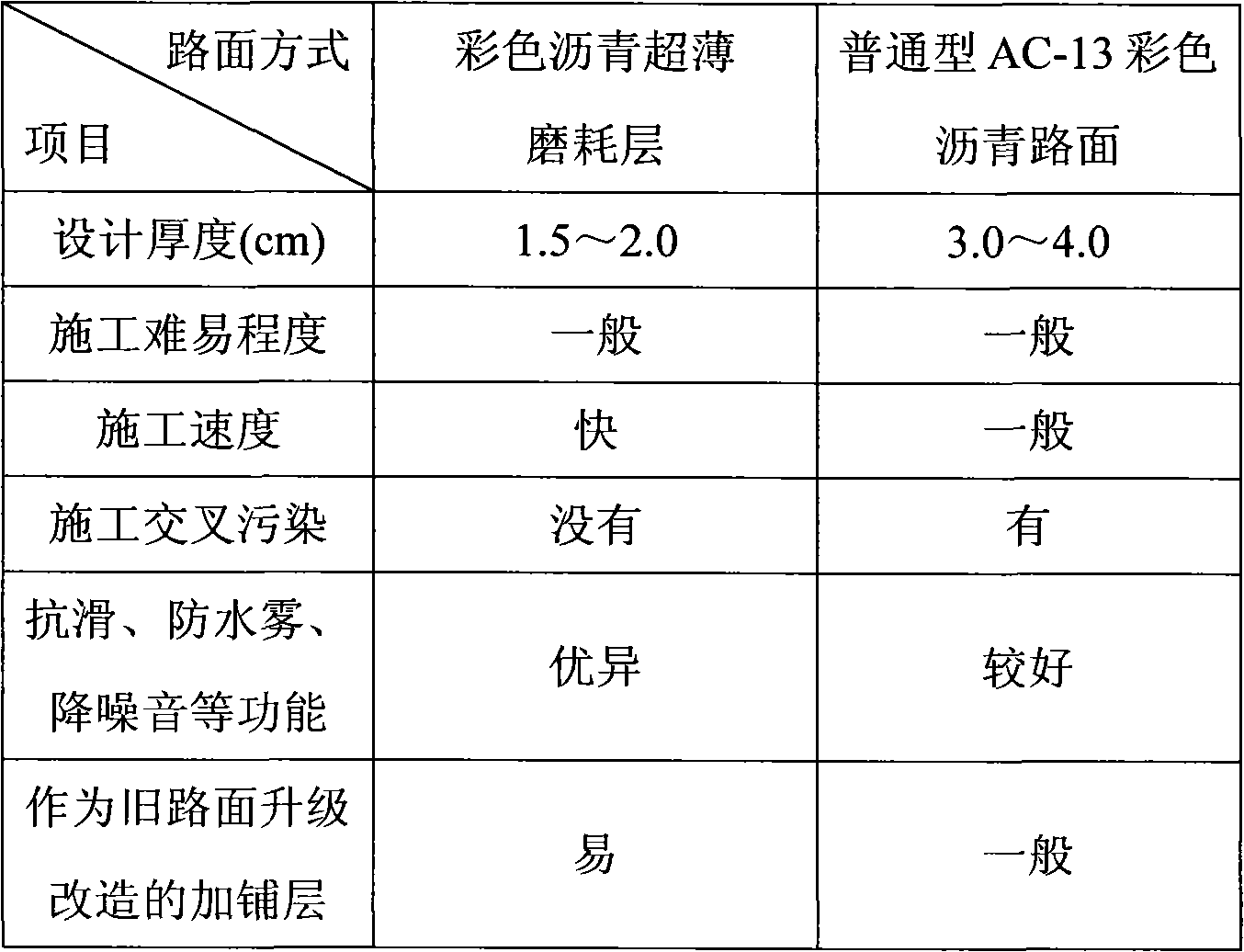

[0034] The ultra-thin wearing layer of colored asphalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com