Anti-disturbance concrete and preparation method thereof

An anti-disturbance, concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low early strength of ordinary concrete, long time interval between initial setting and final setting, etc., and achieve high crack resistance. properties, improved strength and durability, high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

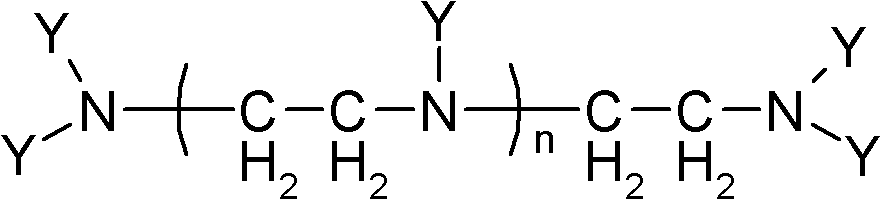

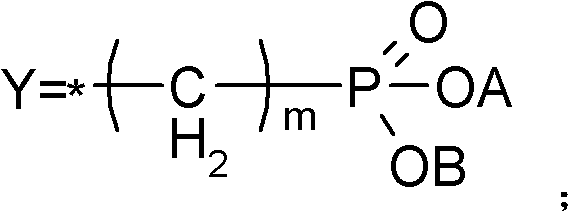

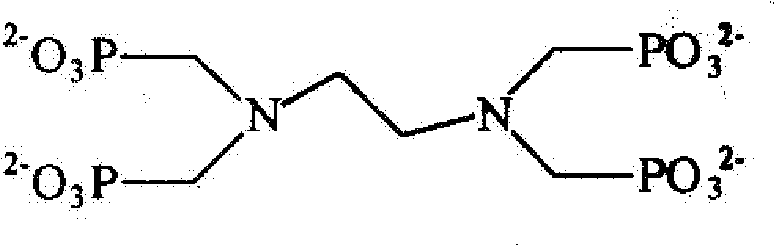

Image

Examples

Embodiment Construction

[0058] The present invention is further set forth below in conjunction with embodiment. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

[0059] Anti-disturbance concrete under different cementitious material dosages in Examples 1-3

[0060] During the preparation, the ordinary Portland cement with a strength grade of 42.5 produced by Chongqing Kehua Cement Factory was selected as the cement, and the first-class fly ash produced by Guizhou Zunyi Power Plant was used as the fly ash. The polycarboxylate superplasticizer is a polycarboxylate superplasticizer SP1 produced by Mapei Co., Ltd., with a solid content of 30%. The anti-disturbance concrete admixture is powder, and the dosage is between 5-8%.

[0061] The preparation method of anti-disturbance concrete admixture of the present invention is as follows:

[0062] First of all, select various raw materials that meet the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com