Copper germinate nano-wire and preparation thereof

A copper germanate and nanowire technology, applied in chemical instruments and methods, germanium compounds, inorganic chemistry, etc., can solve problems such as no copper germanate nanowire structure, achieve batch preparation, simple preparation process, The effect of low growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

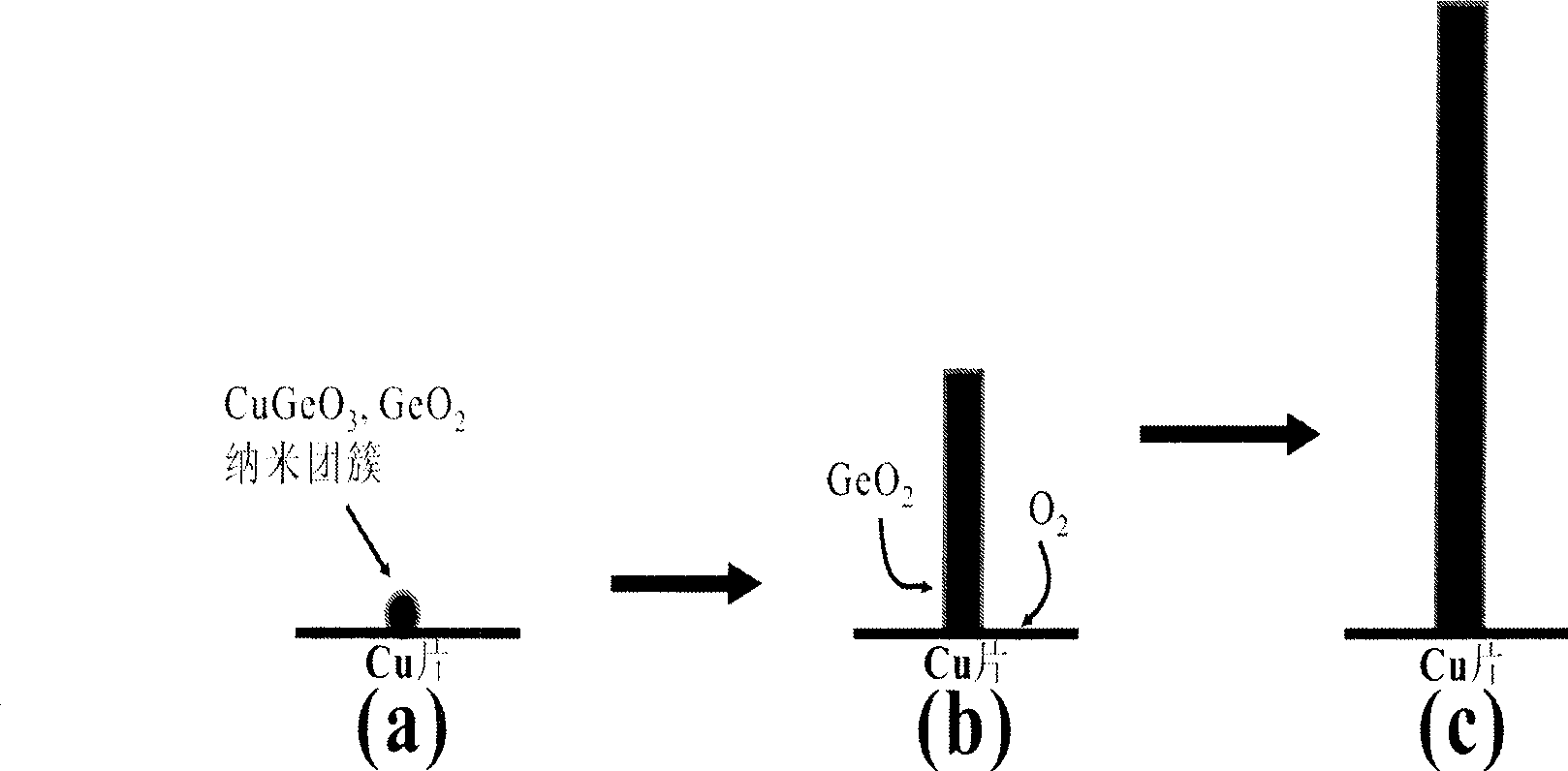

Method used

Image

Examples

Embodiment 1

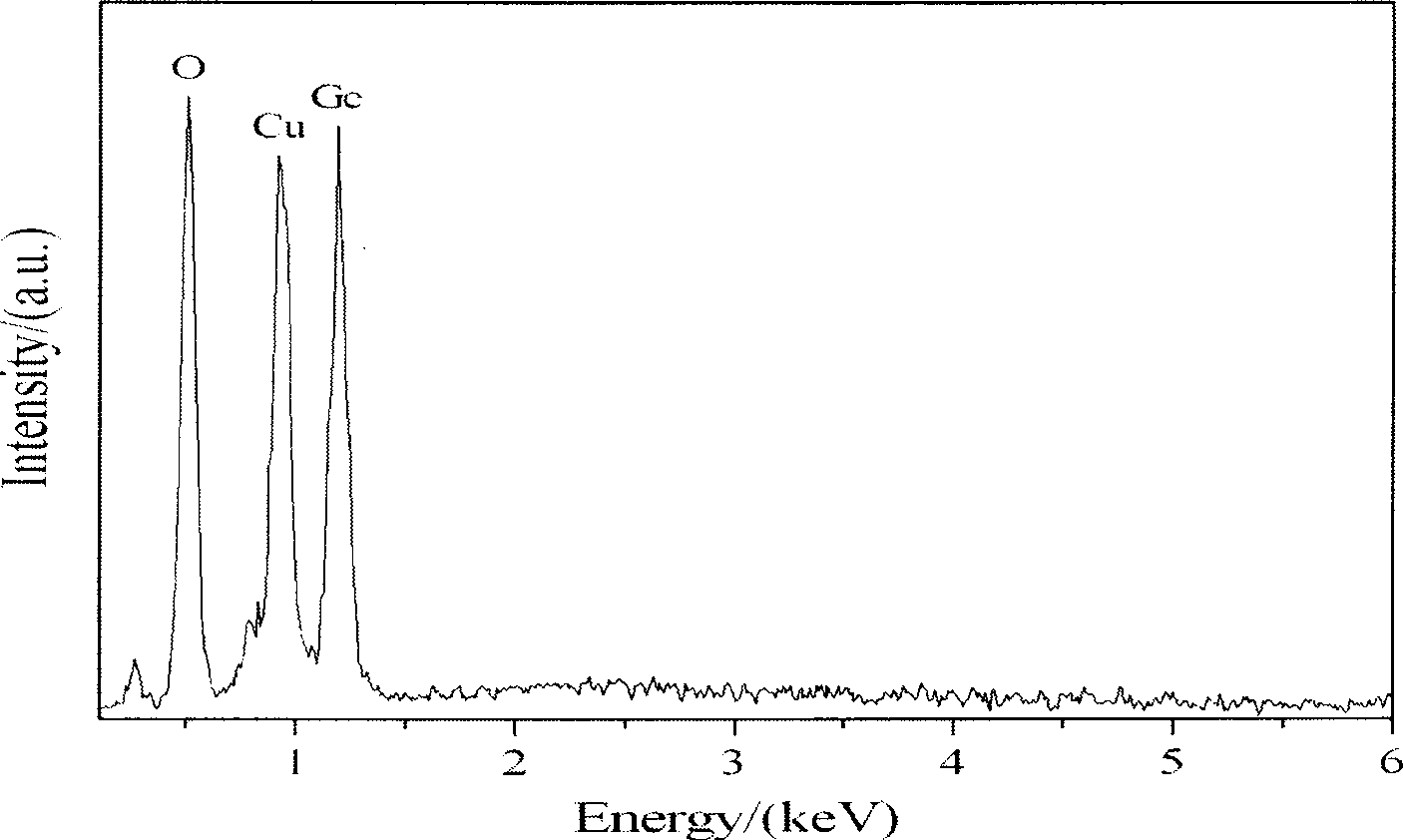

[0029]Example 1: A copper sheet with a size of about 6×2 cm was ultrasonically cleaned in distilled water for ten minutes, then fixed on the stainless steel support in the middle of the reaction kettle, and then germanium dioxide accounting for 1% by weight of the solvent was mixed with distilled water Put it in a sealed reaction kettle, the total amount of germanium dioxide and solvent accounts for 5% of the reaction kettle container, under the uniform stirring of the magnetic stirrer, keep the temperature at 200°C and the pressure of 1-2MPa for 24 hours, and prepare on the copper sheet A velvet-like light blue deposit uniformly deposited on the surface was obtained, and copper germanate nanowires with a length greater than 10 μm, a relatively uniform diameter distribution, and an average diameter of about 100 nm were obtained.

Embodiment 2

[0030] Example 2: Ultrasonic cleaning of a copper sheet with a size of about 6×2 cm in distilled water for ten minutes, then fixing it on the stainless steel support in the middle of the reaction kettle, and then mixing germanium dioxide accounting for 5% by weight of the solvent with distilled water Put it in a sealed reaction kettle, the total amount of germanium dioxide and solvent accounts for 5% of the reaction kettle container, under the uniform stirring of the magnetic stirrer, keep the temperature at 200°C and the pressure of 1-2MPa for 12 hours, and prepare on the copper sheet A velvet-like light blue deposit uniformly deposited on the surface was obtained, and copper germanate nanowires with a length greater than 10 μm, a relatively uniform diameter distribution, and an average diameter of about 100 nm were obtained.

Embodiment 3

[0031] Example 3, ultrasonically clean a copper sheet with a size of about 6×2 cm in distilled water for ten minutes, then fix it on the stainless steel support in the middle of the reaction kettle, and then mix germanium dioxide accounting for 5% by weight of the solvent with distilled water Put it in a sealed reaction kettle, the total amount of germanium dioxide and solvent accounts for 8% of the reaction kettle container, under the uniform stirring of the magnetic stirrer, keep the temperature at 250°C and the pressure of 2-4MPa for 24 hours, and prepare on the copper sheet A velvet-like light blue deposit uniformly deposited on the surface was obtained, and copper germanate nanowires with a length greater than 10 μm, a relatively uniform diameter distribution, and an average diameter of about 100 nm were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com