Method for synthesizing bimodal silicon-aluminum mesoporous material

A technology of mesoporous materials and synthesis methods, applied in the direction of crystalline aluminosilicate zeolites, etc., can solve the problems of single pore size distribution, high price, and difficulty in reducing the cost of organosilanes, and achieve unique properties and reduced synthesis costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] ①Weigh 5.0g of fly ash, add 4.0g of NaOH solid, add water to dissolve NaOH, mix thoroughly, dry in an oven, calcinate in a muffle furnace at 700°C for 15min, add distilled water to dissolve, ultrasonically oscillate for 10min, then filter, and filtrate in a water bath at 70°C Volatile to 93mL, this is silicon source;

[0037] ② Dissolve 1.10g of P123 in a small amount of distilled water, stir magnetically for 60min, add the above silicon source dropwise at a rate of 8 seconds per drop, add 30mL concentrated HCl after the drop, stir evenly, and react with magnetic stirring at 40°C for 24 hours;

[0038] ③Put the above reactant into a polytetrafluoroethylene bottle, seal and crystallize at 100°C for 48 hours, cool, wash and filter, and dry at room temperature.

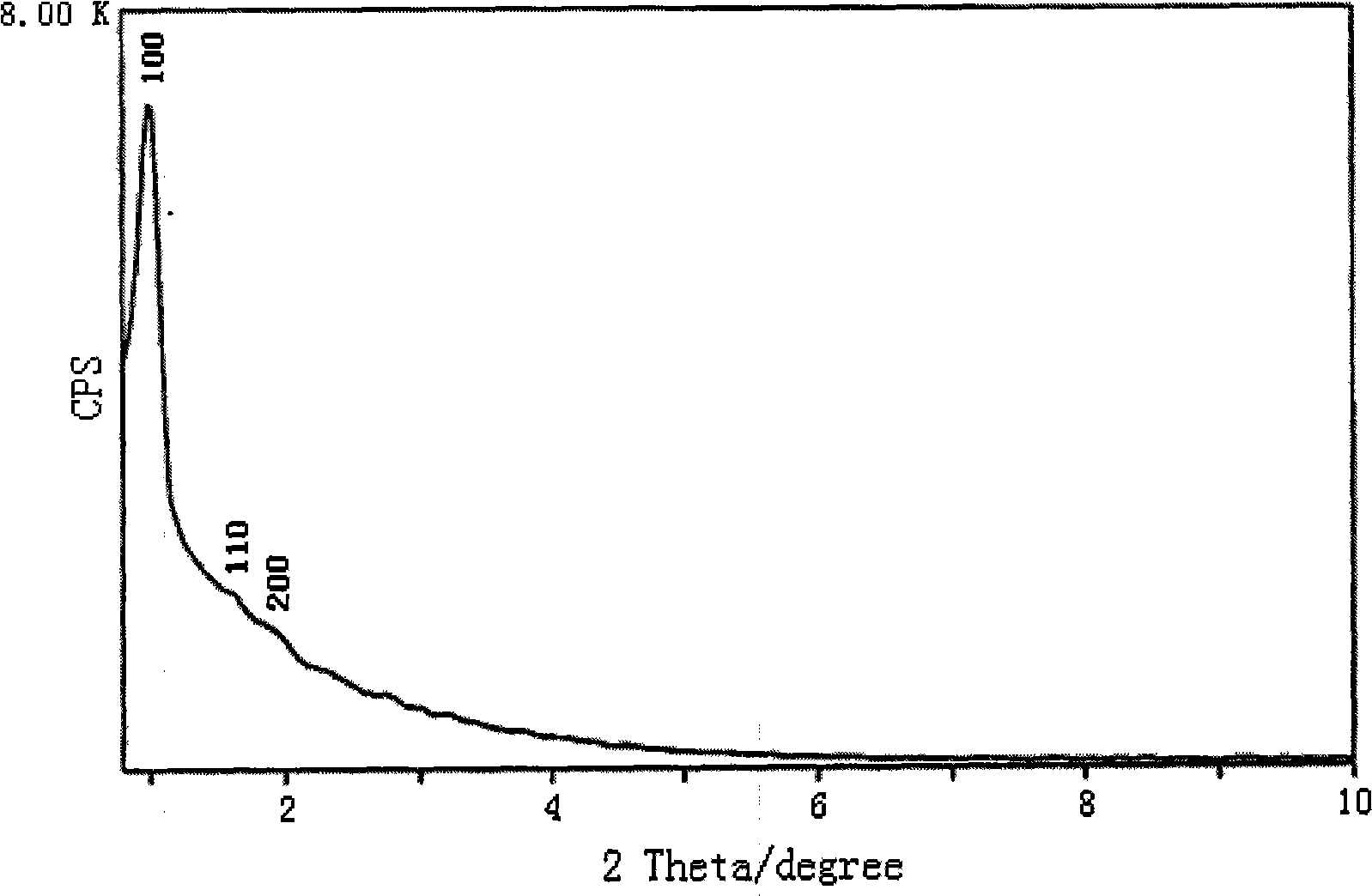

[0039] ④The above-mentioned dry matter was transferred to a Soxhlet extractor, and extracted continuously for 42 hours with absolute ethanol to obtain 1.97 g of mesoporous material product,

[0040] ⑤ The product...

Embodiment 2

[0042] ① Weigh 3.0g of fly ash, add 15.0g of 32°Bé grass pulp black liquor, dry in an oven, calcinate in a muffle furnace at 700°C for 15min, add distilled water and 5mL of 1mol / L NaOH, oscillate ultrasonically for 10min and then filter. The filtrate was evaporated to 42mL in a water bath at 70°C, which was the source of silicon.

[0043] ② Dissolve 1.05g P123 in a small amount of distilled water, stir magnetically for 60min, add the above silicon source dropwise at a speed of 9 seconds per drop, add 15mL concentrated HCl after dripping, stir evenly, stir magnetically at 40°C for 24 hours,

[0044] ③Put the above reactant into a polytetrafluoroethylene bottle, seal and crystallize at 100°C for 48 hours, cool, wash and filter, and dry at room temperature.

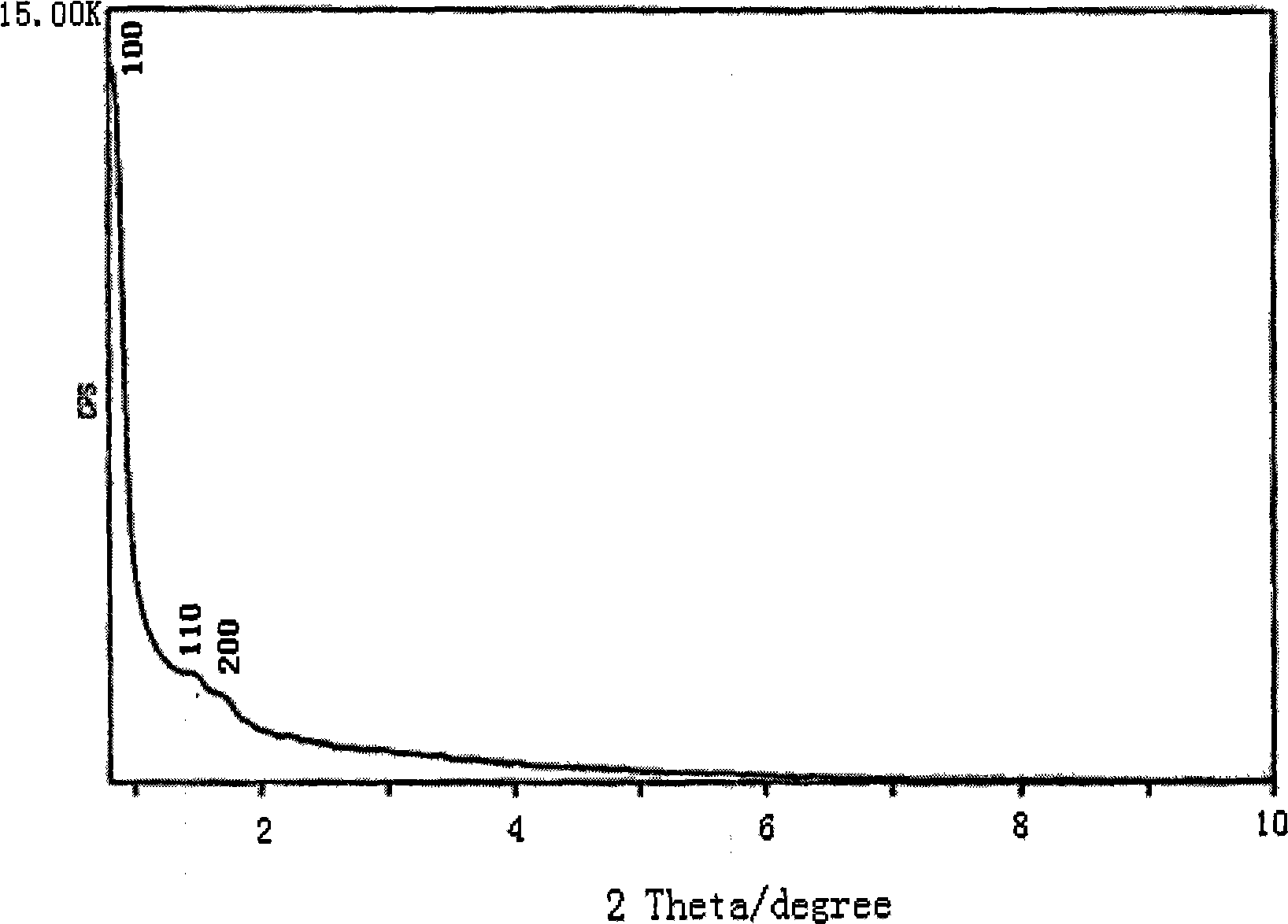

[0045] ④The above dry matter was transferred to a Soxhlet extractor, and extracted continuously with absolute ethanol for 36 hours to obtain 1.24 g of mesoporous material product

[0046] ⑤ The product name is MSPS-160, whi...

Embodiment 3

[0048] ①Weigh 3.0g of fly ash, add 3.0g of NaOH solid, add water to dissolve NaOH, mix thoroughly, dry in oven, calcinate in muffle furnace at 850°C for 15min, add distilled water to dissolve, ultrasonically oscillate for 10min and filter, filtrate in water bath at 70°C Volatile to 48mL, this is silicon source;

[0049] ② Dissolve 1.10g of P123 in a small amount of distilled water, stir magnetically for 60min, add the above silicon source dropwise at a rate of 10 seconds per drop, add 2.15g concentrated HCl after dripping, stir evenly, and react with magnetic stirring at 40°C for 24 hours;

[0050] ③Put the above reactant into a polytetrafluoroethylene bottle, seal and crystallize at 100°C for 48 hours, cool, wash and filter, and dry at room temperature.

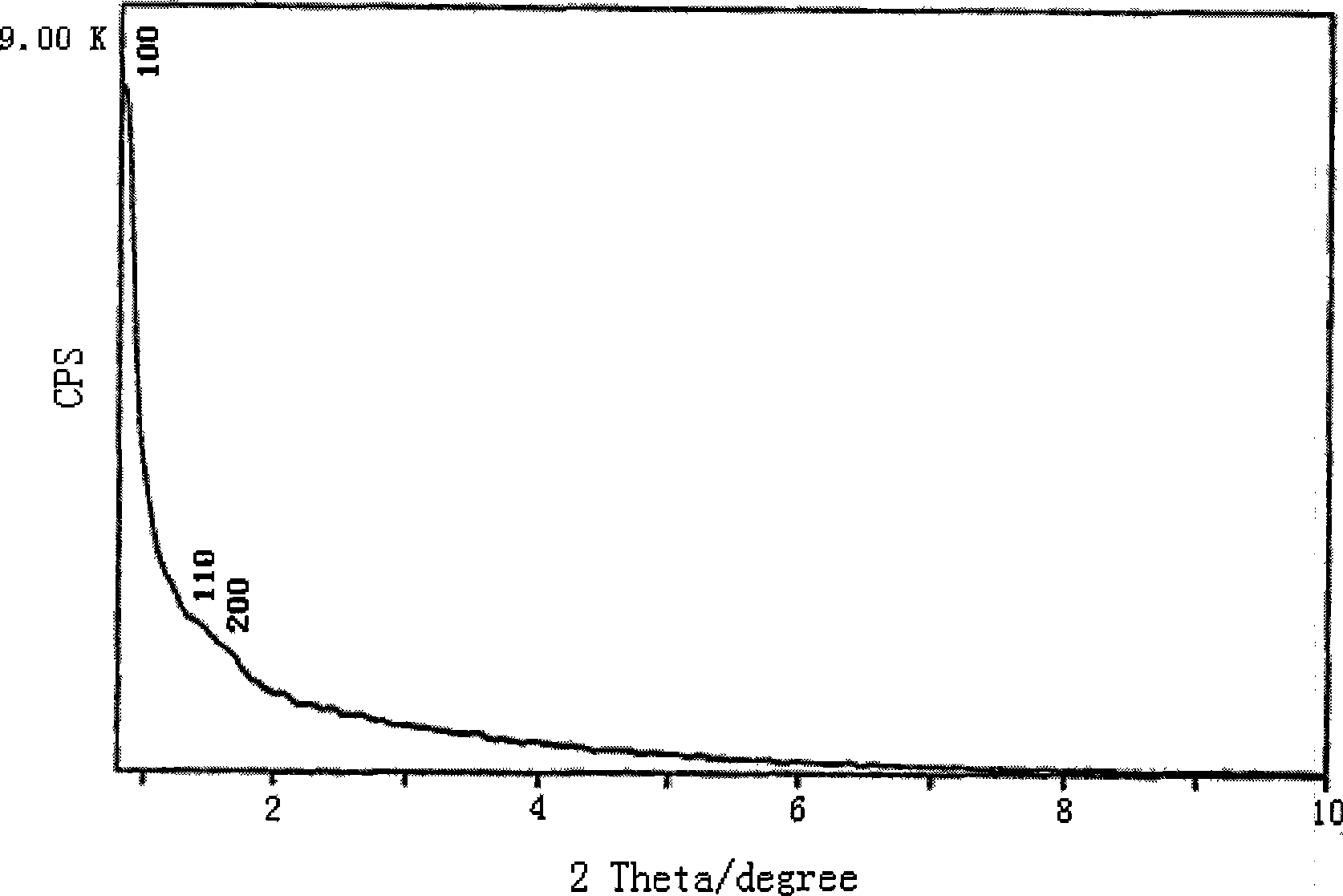

[0051] ④The above-mentioned dry matter was transferred to a Soxhlet extractor, and extracted continuously for 42 hours with absolute ethanol to obtain 1.44 g of mesoporous material product,

[0052] ⑤ The product name is MS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com