Preparing method of nano-modified high permeability resistant concrete

A nano-modification and concrete technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems that cannot meet the requirements of concrete materials, the impact of concrete comprehensive performance and impermeability of concrete, and the impermeability of concrete Improve limited and other issues to achieve the effect of improving structural strength and impermeability, improving impermeability, and optimizing particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

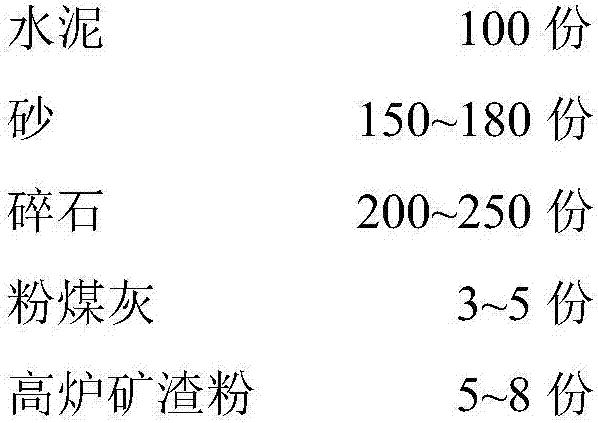

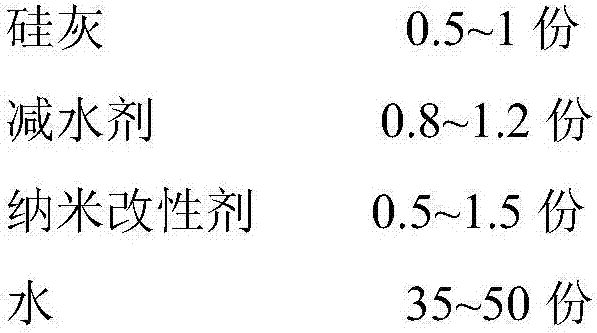

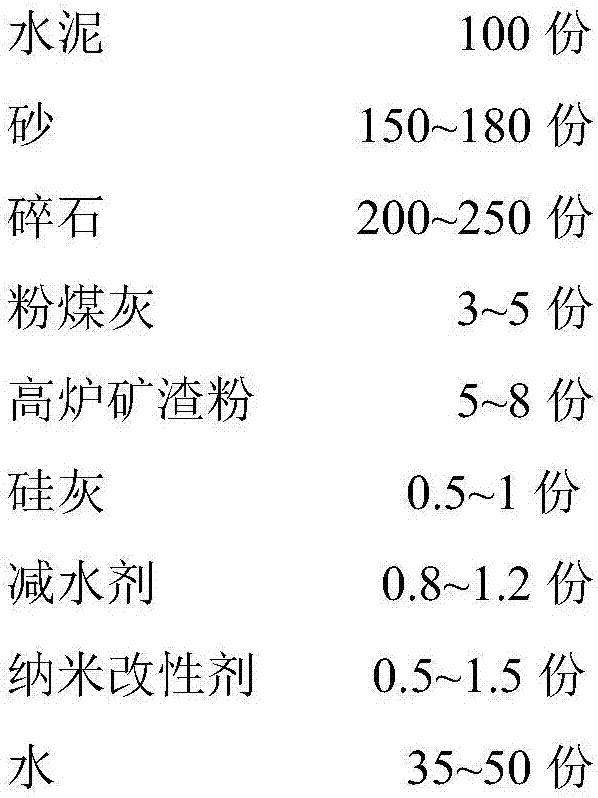

[0026] Nano-modified high-impermeability concrete is made by mixing the following raw material components in parts by weight: 100 parts of cement, 150 parts of sand, 200 parts of crushed stone, 3 parts of fly ash, 8 parts of blast furnace slag powder, and 0.5 parts of silica fume ; 1.2 parts of water reducer, 1.5 parts of nano-montmorillonite, 50 parts of water.

[0027] The preparation method of above-mentioned nano-modified high impermeability concrete is as follows:

[0028] (1) Add cement, sand, gravel, fly ash, blast furnace slag powder, and silica fume according to the proportion by weight to the concrete mixer and dry mix for 2 minutes until each base material is fully mixed;

[0029] (2) Stir the nano-montmorillonite and water reducer in the weight ratio and half of the weight of water to fully mix, use a centrifuge to carry out centrifugal dispersion, and then add it to the mixture of step (1) and stir for 2 minutes; Add the other half of the weight of water into the...

Embodiment 2

[0032] Nano-modified high-impermeability concrete is made by mixing the following raw material components in parts by weight: 100 parts of cement, 180 parts of sand, 250 parts of crushed stone, 5 parts of fly ash, 5 parts of blast furnace slag powder, and 1 part of silica fume ; 0.8 parts of water reducer, nano-CaCO 3 0.5 parts, 35 parts of water.

[0033] The preparation method of above-mentioned nano-modified high impermeability concrete is as follows:

[0034] (1) Add cement, sand, gravel, fly ash, blast furnace slag powder, and silica fume according to the proportion by weight to the concrete mixer and dry mix for 2 minutes until each base material is fully mixed;

[0035] (2) the nano-CaCO of described weight ratio 3 Stir with the water reducer and half of the weight of water to mix well, use a centrifuge for centrifugal dispersion, add to the mixture of step (1) and stir for 2 minutes; then add the other half of the weight of water into the mixer and continue stirring ...

Embodiment 3

[0038] Nano-modified high-impermeability concrete is made by mixing the following raw material components in parts by weight: 100 parts of cement, 160 parts of sand, 230 parts of gravel, 4 parts of fly ash, 7 parts of blast furnace slag powder, and 0.8 parts of silica fume ; 1 part of water reducer, nano-SiO 2 1 part, 45 parts of water.

[0039] The preparation method of above-mentioned nano-modified high impermeability concrete is as follows:

[0040] (1) Add cement, sand, gravel, fly ash, blast furnace slag powder, and silica fume according to the proportion by weight to the concrete mixer and dry mix for 2 minutes until each base material is fully mixed;

[0041] (2) the nano-SiO of described weight ratio 2 Stir with the water reducer and half of the weight of water to mix well, use a centrifuge for centrifugal dispersion, add to the mixture of step (1) and stir for 2 minutes; then add the other half of the weight of water into the mixer and continue stirring for 2 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com