Nano modified composite powder for ocean-engineering concrete structure

A technology of concrete structure and composite powder, which is applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problem of reduced alkalinity of reinforced concrete, difficulty in meeting design requirements, and decreased stability of passivation film, etc. problems, to achieve the effect of improving durability, improving submicroscopic structure, improving structural strength and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

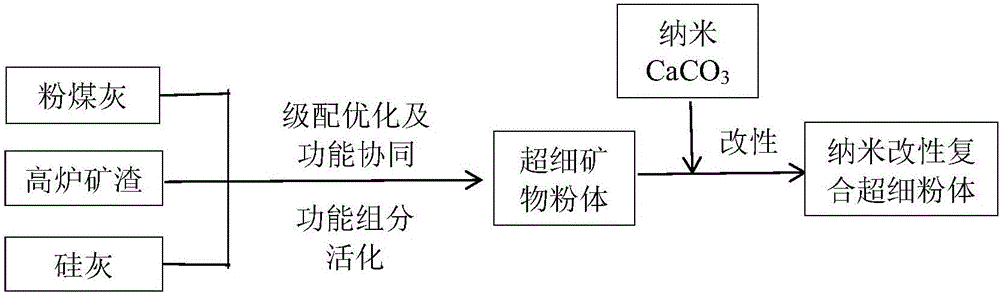

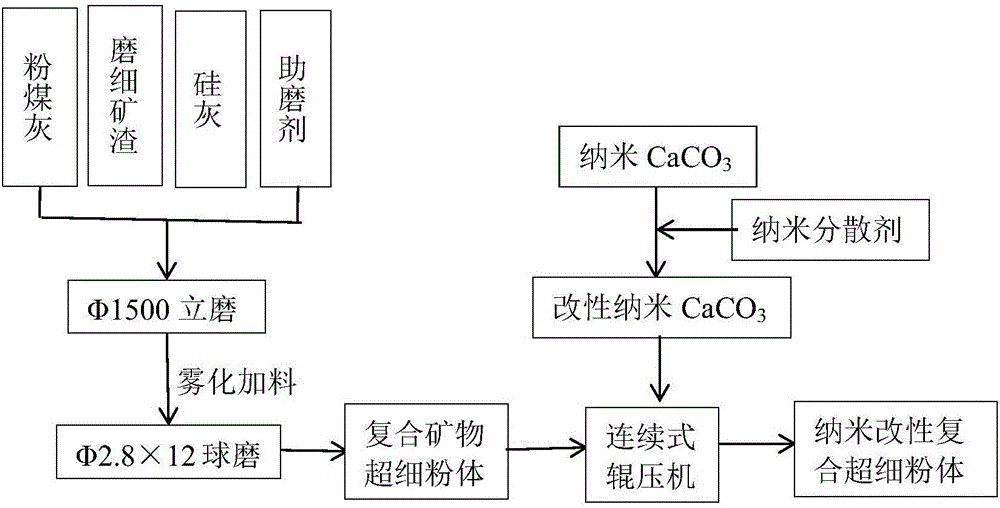

[0031] The preparation method of nano-modified composite powder comprises the following steps:

[0032] (1) The dried nano-CaCO 3 Mix with the nano-dispersant according to the weight ratio, and stir at a constant temperature of 110°C for 30 minutes to prepare the modified nano-CaCO 3 ;

[0033] (2) Take fly ash, blast furnace slag powder and silica fume according to the weight ratio, pre-grind in vertical mill equipment after adding grinding aid; then add in ball mill equipment in the form of atomized feeding, and mix and grind to obtain Mineral ultrafine powder;

[0034] (3) The composite mineral ultrafine powder and modified nano-CaCO 3 After mixing, it is sent to a continuous roller press, and is ground to obtain a nano-modified composite powder.

[0035] The method for using the nano-modified composite powder is to replace an equivalent amount of cement with the nano-modified composite powder for concrete preparation; specifically, the following steps are included:

...

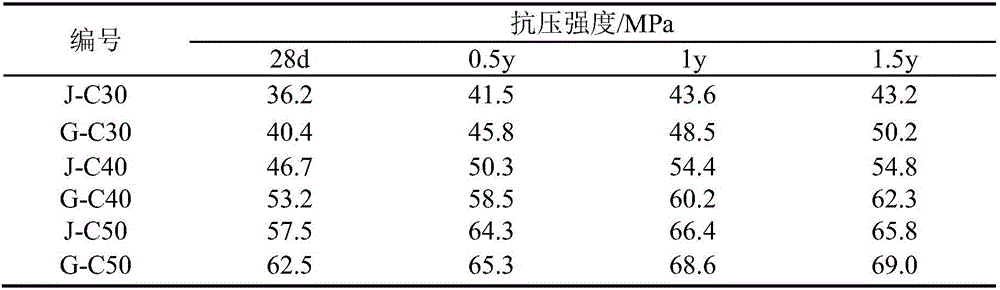

Embodiment 1

[0040] The nano-modified composite powder is made by mixing the following raw material components in parts by weight: 20 parts of fly ash, 40 parts of blast furnace slag powder, 15 parts of silica fume; nano-CaCO 3 7 parts, 1 part of nano-dispersant.

[0041] According to the aforementioned method, the preparation of the nano-modified composite powder and its use in the process of preparing concrete are realized.

Embodiment 2

[0043] The nano-modified composite powder is made by mixing the following raw material components in parts by weight: 30 parts of fly ash, 25 parts of blast furnace slag powder, 20 parts of silica fume; nano-CaCO 3 5 parts, 0.8 parts of nano-dispersant.

[0044] According to the aforementioned method, the preparation of the nano-modified composite powder and its use in the process of preparing concrete are realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com