Recycled aggregate structural concrete and manufacture method

A technology of recycled aggregate and manufacturing method, applied in the field of concrete, can solve the problems of high water absorption, decreased durability, limited application of recycled aggregate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

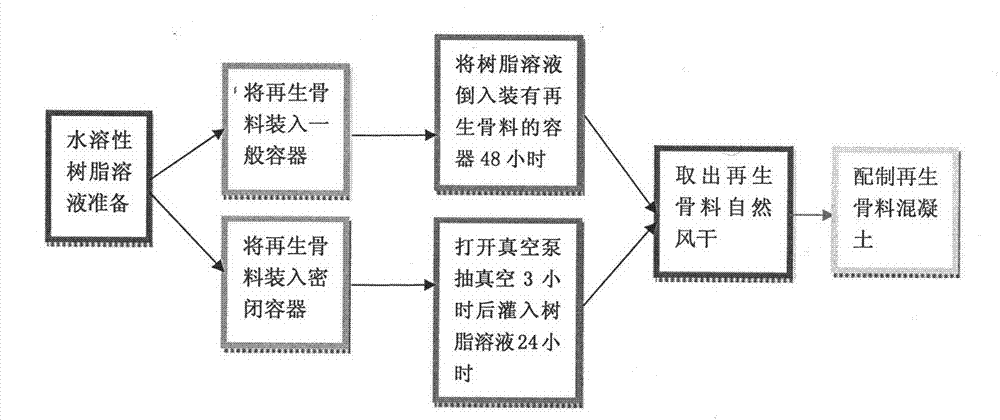

Method used

Image

Examples

Embodiment 1

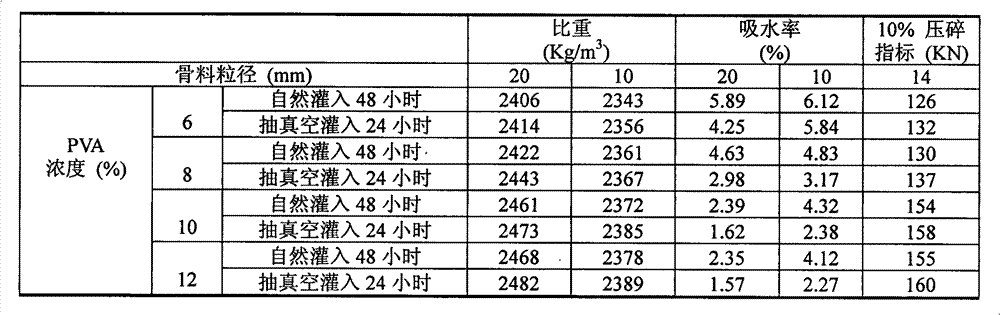

[0017] According to Table 1, the recycled aggregates with a particle size of 20 mm and 10 mm (water absorption before treatment are 6.23% and 7.76%, respectively, and the specific gravity is 2393 kg / m3 and 2356 kg / m3) using different concentrations The physical properties and mechanical properties of the recycled aggregate were measured according to the standard method after the water-soluble resin (PVA) was poured naturally and vacuumized and dried.

[0018] From the data listed in Table 1, it can be seen that with the increase of resin concentration, the specific gravity and crushing index of the recycled aggregate treated by the two filling methods increased, and the water absorption decreased. When the resin concentration exceeds 10%, the performance of the aggregate does not change much. At the same time, it can be seen that although the natural pouring method doubles the time, the effect of improving the performance of the recycled aggregate is not as good as that of the...

Embodiment 2

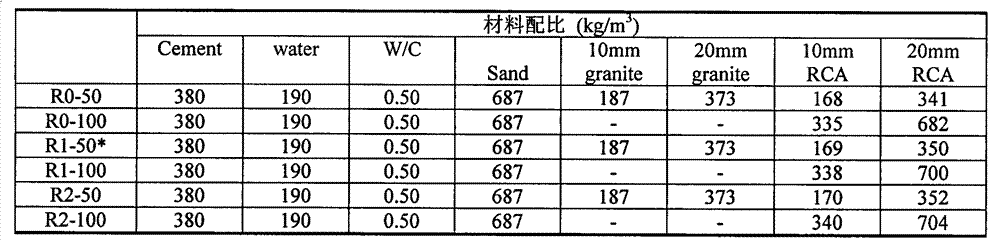

[0022] Table 2 lists the proportions of concrete manufactured with recycled aggregates treated with 10% PVA, while Table 3 lists the mechanical properties and durability of concrete produced according to the proportions of Table 2. It can be seen that the mechanical properties and durability of the recycled aggregate concrete without treatment are poor. Also, the performance of concrete decreases with the increase of recycled aggregate.

[0023] Compared with the concrete made of untreated recycled aggregate, the 28-day compressive strength, splitting strength and elastic modulus of the concrete treated with PVA are greatly improved, the 112-day dry shrinkage rate is reduced, and the 365-day creep is reduced. . 50% recycled aggregate replaces natural aggregate, and its performance fully meets the requirements of structural concrete.

[0024] Table 2 Properties of concrete with different recycled aggregate content

[0025]

[0026] *R1-50, R1-100 refers to the recycled ag...

Embodiment 3

[0030] Table 4 lists the proportions of recycled aggregates treated with 10% PVA at different cement contents, different water-cement ratios, and different mineral additive contents, while Table 5 shows the concrete manufactured according to the proportions in Table 4 performance. It can be seen from Table 5 that the mechanical properties and durability of recycled aggregate concrete can be greatly improved by increasing the cement content, reducing the water-cement ratio, and adding mineral additives such as kaolin powder or silica fume, while adding fly ash will reduce Concrete 28-day strength, but durability of concrete can be improved.

[0031] Table 4 Proportion of recycled aggregate concrete with different cement contents and different water-cement ratios

[0032]

[0033] Table 5 Performance of recycled aggregate concrete with different cement contents and different water-cement ratios

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com