Method for regenerating waste solid for use in road foundation

A technology of road base and solid objects, which is applied in roads, roads, buildings, etc., can solve the problems of polluting the environment, wasting garbage and transportation fees, etc., and achieve the effect of reducing pollution and helping to protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Recycled construction waste waste concrete blocks and waste bricks are used as raw materials, and after being crushed by a crusher and separated by a magnetic separator, it becomes a continuously graded recycled graded solid material with a particle size of 0-30mm.

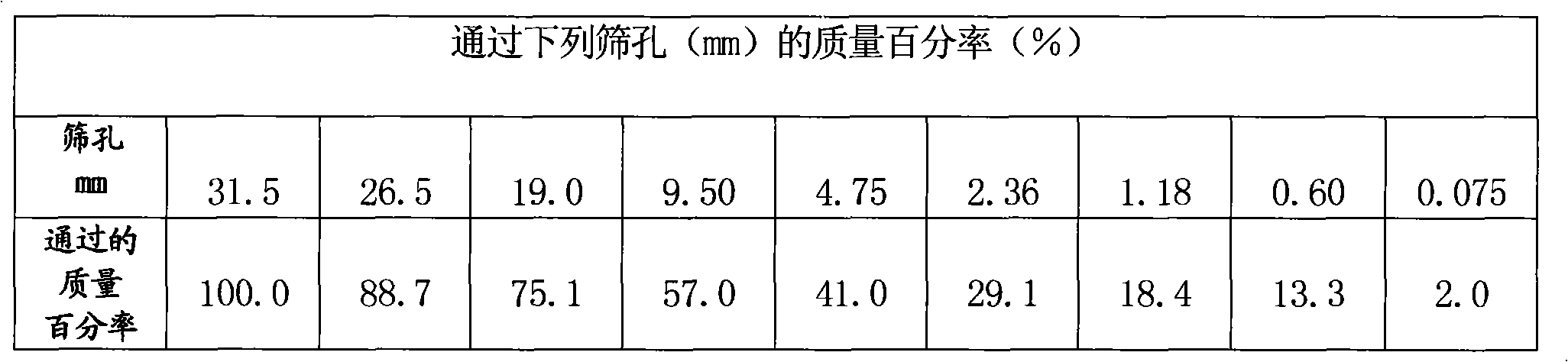

[0024] See the following table for the specific particle gradation of recycled grade solid materials:

[0025]

[0026] The crushing value of the obtained regenerated graded solid material is 33.4%. Among the regenerated graded solid materials with a particle size above 0.5mm, the content of waste concrete blocks accounts for 52.2%, the content of waste bricks accounts for 47.8%, and the content of waste bricks accounts for 47.8%. The plasticity index of fine-grained soil is 8.1.

[0027] After testing, the recycled graded solid material complies with "Technical Specifications for Construction of Highway Pavement Base" (JTJ 034-2000), "Code for Design of Highway Asphalt Pavement" (JTG D50-2006), "Constru...

Embodiment 2

[0030] Lime, fly ash, and cement components were mixed in the same regenerated graded solid material as in Example 1.

[0031] The effective CaO+MgO used in the lime is 56.8% grade III slaked lime.

[0032] The fly ash with the indicators listed in the table below is adopted for the fly ash:

[0033] indicators

(%)

loose square density

(Kg / m 3 )

SiO 2

(%)

Al 2 o 3

(%)

Fe 2 o 3

(%)

CaO

(%)

MgO

(%)

SO 2

(%)

detection value

8.44

680

47.55

32.48

5.44

2.67

0.75

0.45

[0034] Fly ash fineness: 0.3mm sieve through the mass percentage of 100%; 0.15mm sieve through the mass percentage of 99.2%; 0.075mm sieve through the mass percentage of 88.2%.

[0035] The cement adopts 32.5MPa retarded cement, and the initial setting time of the cement is more than 3 hours and the final setting time is more than 6 ho...

Embodiment 3

[0039] Using construction waste containing waste concrete blocks, waste bricks, waste tiles, and waste gravel as raw materials, after being crushed by the RM80 type stone crusher and separated by a magnetic separator, it becomes a continuously graded regeneration with a particle size of 0-30mm grade solid materials.

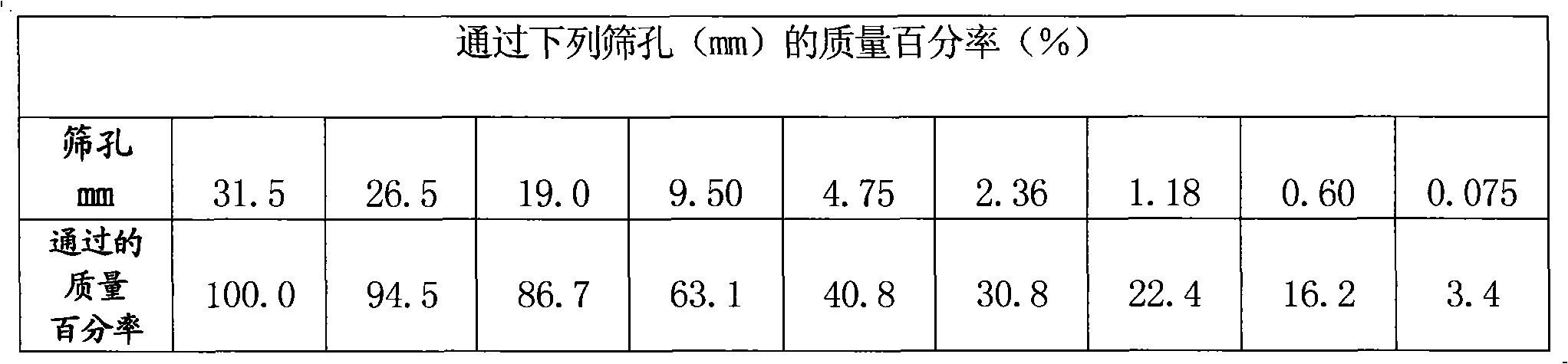

[0040] The specific particle gradation of the recycled graded solid material is shown in the table below:

[0041]

[0042] The crushing value of the obtained regenerated graded solid material is 28.4%. Among the regenerated graded solid materials with a particle size above 0.5 mm, the content of waste concrete blocks accounts for 62.7%, the remaining waste bricks account for 13.2%, and the content of waste tiles accounts for 21.6%, the waste gravel content accounts for 2.5%, and the plasticity index of fine-grained soil below 0.5mm in the material is 6.8.

[0043] Mix cement and fly ash into the above-mentioned regenerated graded solid material, mix the regene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com