Mechanism for feeding cloth in X and Y directions for computerized embroidery machine

A cloth feeding mechanism and embroidery machine technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc. It can solve the problems of short service life of linear guide rails, low service life of rhombic bearings, and poor embroidery quality. The effect of extended service life, reduced maintenance times, high innovation and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

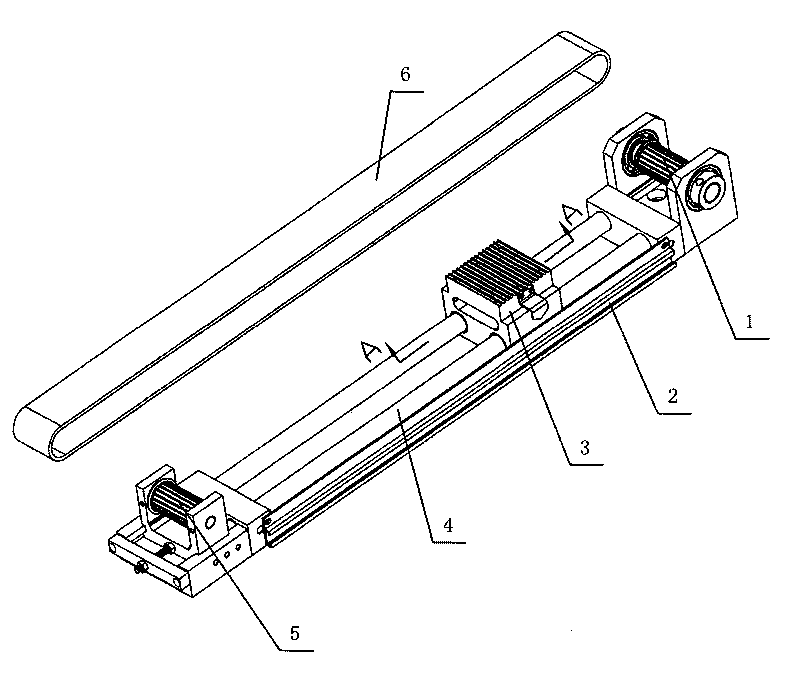

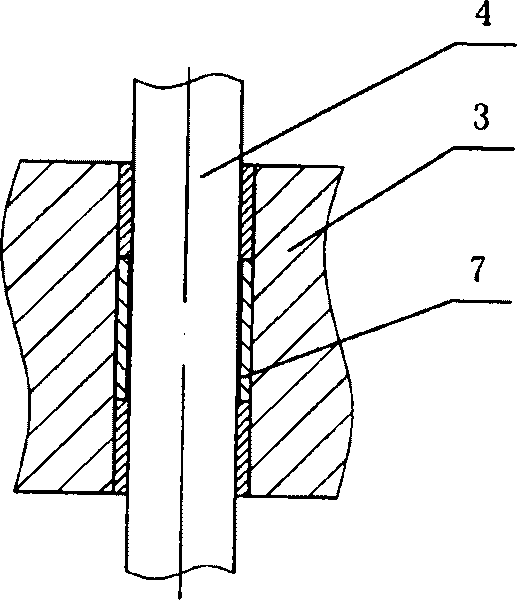

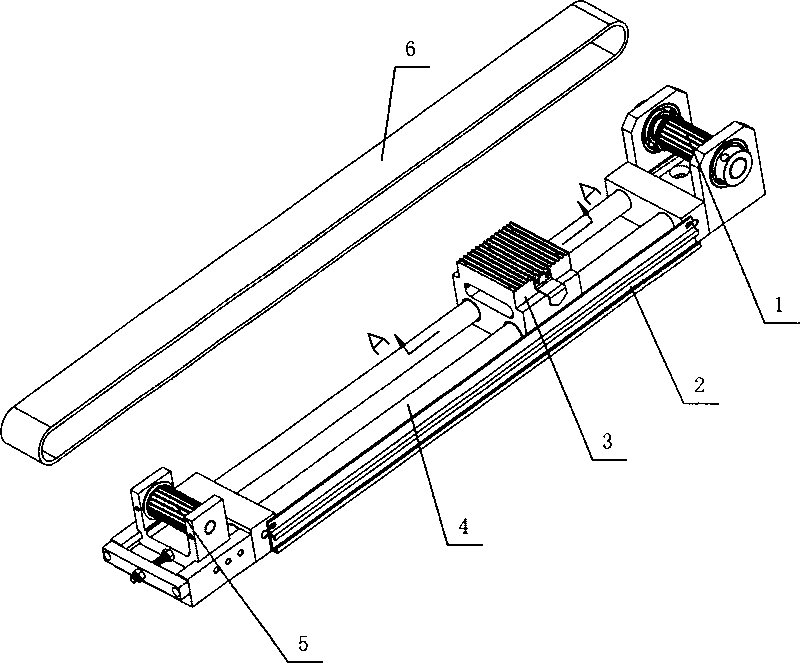

[0013] A cloth feeding mechanism in the X and Y directions of a computerized embroidery machine is suitable for cloth feeding in the X and Y directions of an embroidery machine. Two guide columns are installed in parallel longitudinally on the shaft seat between the driving wheel and the driven wheel. The guide columns are sheathed in the guide holes in the slide block, so that the slide block can be guided and driven on the guide posts through the synchronous belt meshing drive. In order to improve the service life of the whole mechanism and the running effect of the slider, a composite material shaft sleeve 7 with extremely high wear resistance is embedded in the guide hole in the slider. A driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com