Sealing device of circular cooler

A technology of a sealing device and a ring cooler, which is applied in the field of the sealing device of the ring cooler, can solve the problems that the expected sealing effect cannot be obtained, the working conditions of the ring cooler are bad, and the sealing effect becomes a problem, so as to solve the maintenance difficulty and improve the adjacent Condition, sealing effect improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

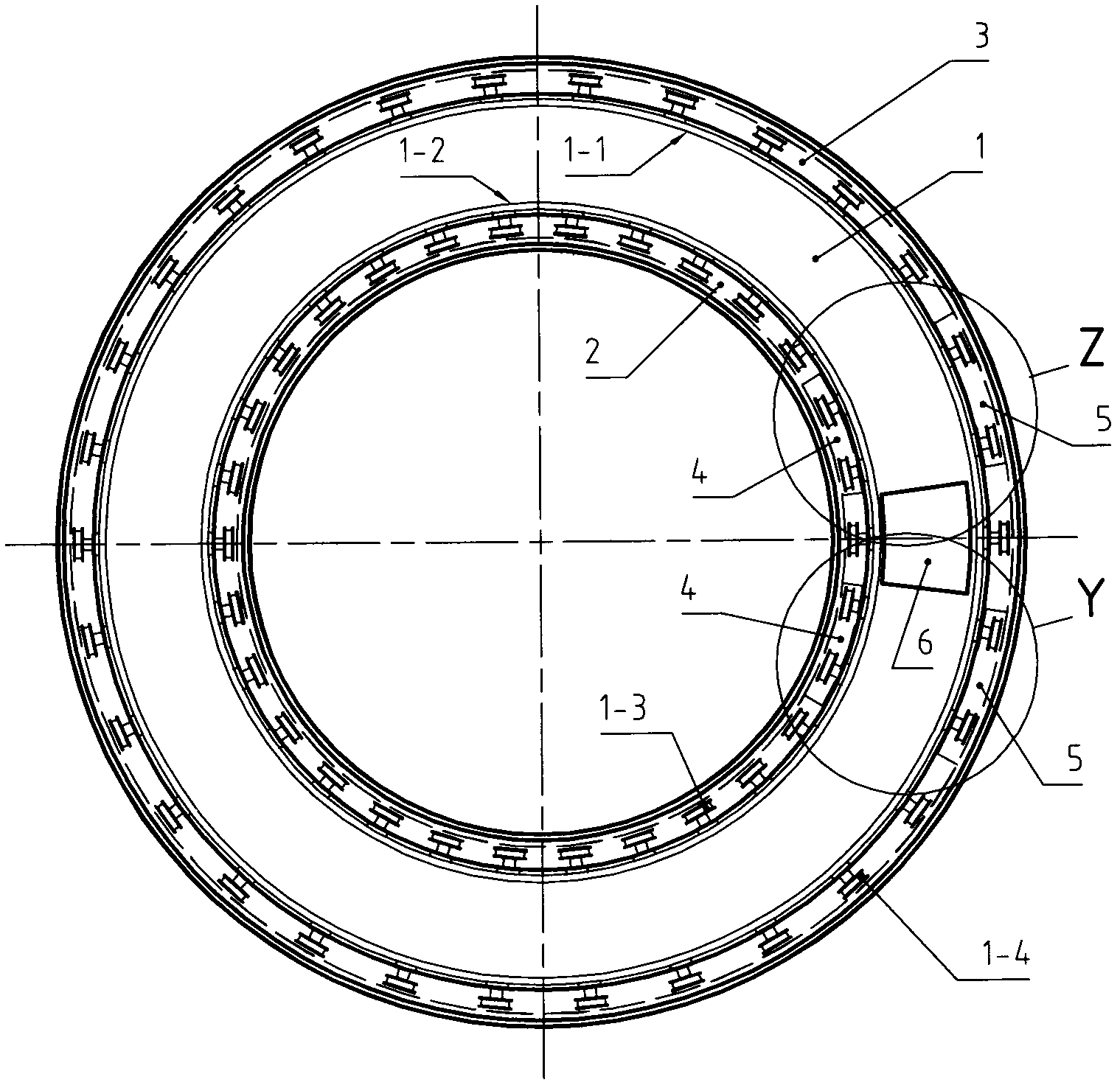

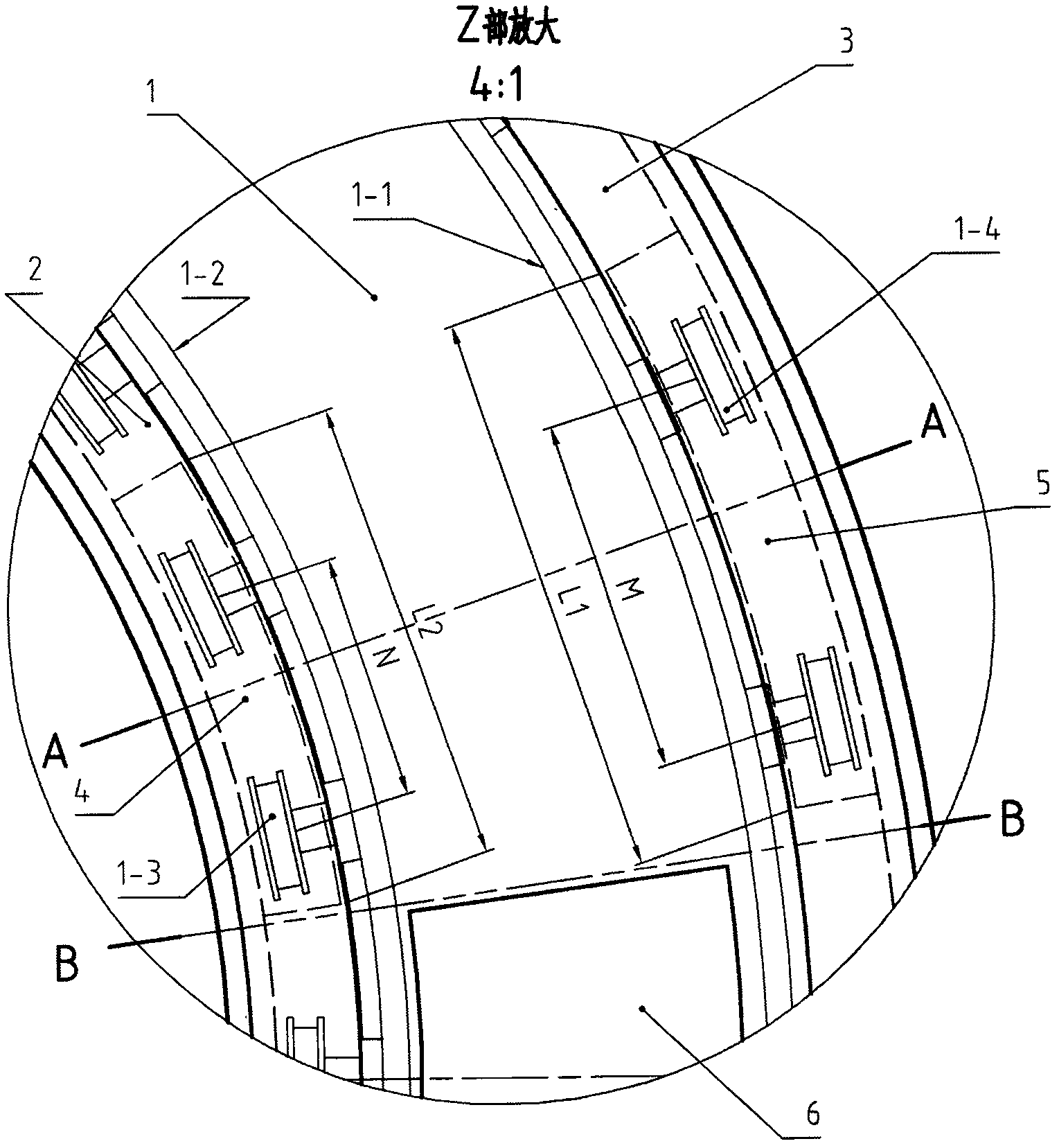

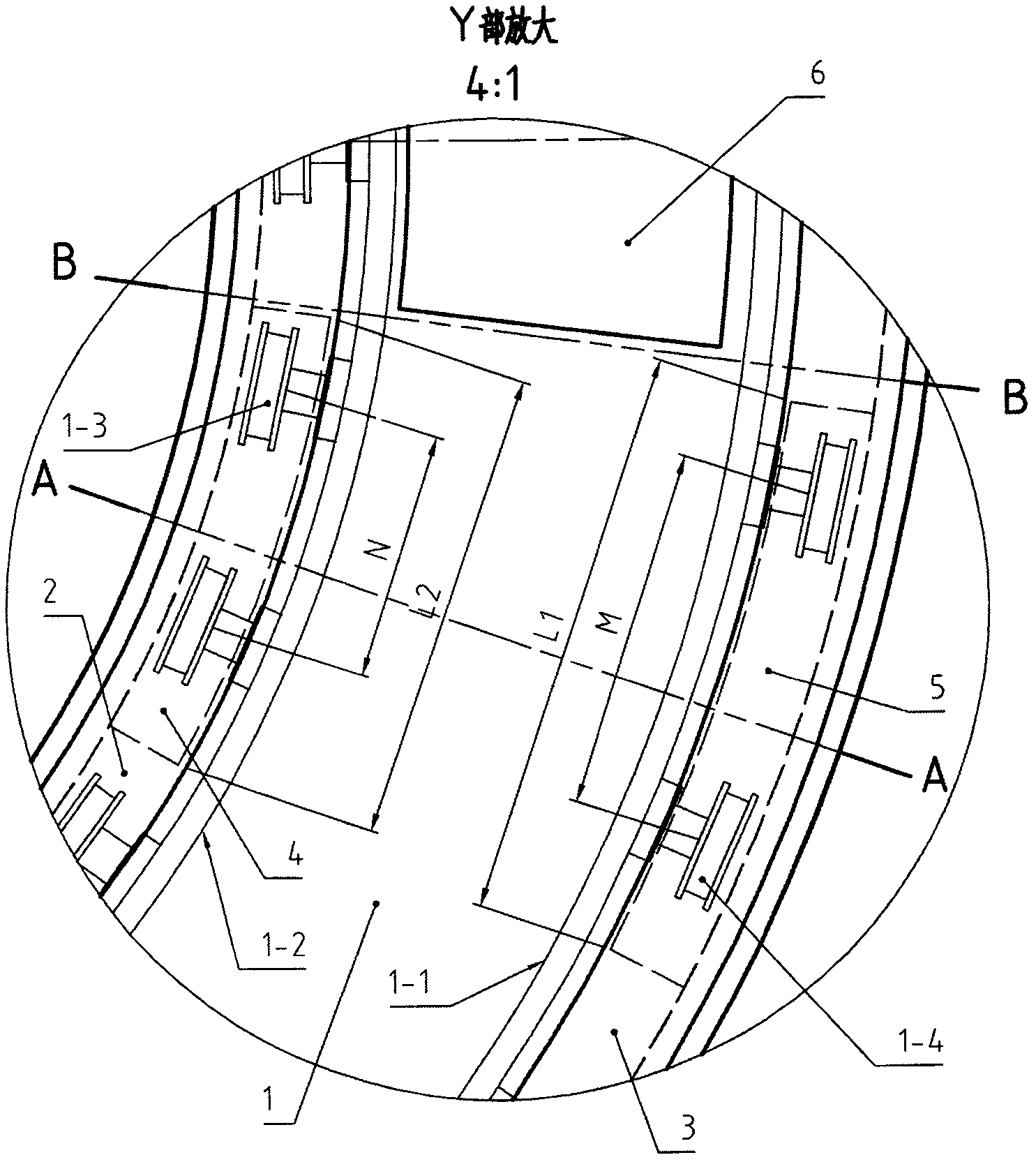

[0023] Example 1, such as Figure 1 to Figure 5 shown.

[0024] exist figure 1 Among them, 1 is the general outline of the circular motion part of a certain annular cooler; among them, 1-1 is the outer ring of the rotary frame assembly (hereinafter referred to as the outer ring) of the circular cooler part of the annular cooler, and 1-2 is the The inner ring of the rotary frame assembly of the circular motion part of the annular cooler (hereinafter referred to as the inner ring), and their rotary motion is synchronous; 1-3 is the wheel of the circular motion part of the annular cooler - the wheel in the grate plate assembly The inner wheel in (hereinafter referred to as the inner wheel), and 1-4 is the outer wheel (hereinafter referred to as the outer wheel) of the wheels in the wheel-grit plate assembly of the circular motion part of the annular cooler. 2 is a closed cover-type structure that includes a sealing mechanism, contains the air leakage belt of the annular cooler...

Embodiment 2

[0032] Example 2, such as Figure 6 ~ Figure 11 shown.

[0033] This embodiment is a change carried out on the basis of Embodiment 1, and its main difference with Embodiment 1 is that it is on the wind blocking section, specifically the gap reserved in the wind blocking section (such as Figure 4 Shown by the dimension H in ), a flexible windshield is installed, and the rest are the same as in Embodiment 1. In this embodiment, the flexible windshield is made of silicone rubber, but it does not exclude the use of other rubbers, especially other heat-resistant rubbers, and it can also be made of elastic metal Sheet or metal foil, etc.

[0034] Image 6 is in Figure 4 The situation after the flexible windshield 9 has been added on the basis of the above. Due to structural requirements, the windshield 9 is divided into many pieces, which are respectively marked as 9-1, 9-2, 9-3, ... and so on. due to Image 6 It is difficult to distinguish its details in , so the Image 6...

Embodiment 3

[0041] Example 3, such as Figure 12 to Figure 20 shown.

[0042] This embodiment is a modification made on the basis of Embodiment 1, and the meanings of symbols that are not described again are also the same as those of Embodiment 1. Its main difference with embodiment 1 is:

[0043] 1. The hood structure 2 and 3 are disconnected at the discharge port 6 to leave enough space for easy maintenance of the trolley.

[0044] 2. The sealing mechanisms 2-2 and 3-2 included in the cover structure 2 and 3 are replaced by the elastic plate-slider type mechanisms 2-4 and 3-4.

[0045] Figure 12 It is a top view of this embodiment, showing the situation that the bell structures 2 and 3 are disconnected at the discharge port 6 . It should be noted that when the cover structures 2 and 3 are disconnected, in order to maintain the continuity of the sealing mechanism, the continuity of at least one of the elastic plate or the sliding plate must be maintained; in this embodiment, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com