Method for controlling surrounding rock deformation of gateway subjected to repeated overhead mining by using hollow grouting anchor cable

A grouting anchor cable, hollow technology, applied in mining equipment, earthwork drilling, installation of anchor rods, etc., can solve the problem of insignificant technical effect, and can solve the problem of large deformation of roadway, improve integrity, and reduce roadway support. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

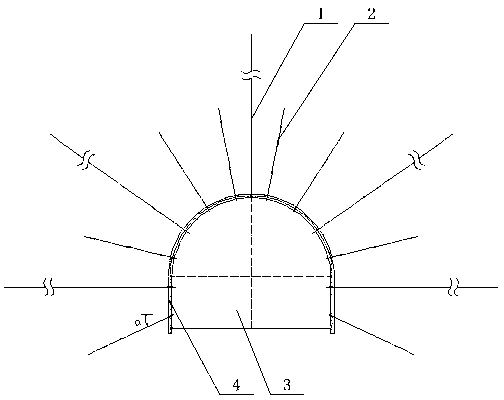

[0021] In the figure, the roadway in this example is a floor roadway with an inclination angle of 13°. The section of the repaired roadway is: bottom width×middle height=4100mm×3350mm, affected by at least 3 times of cross mining on the overlying working face, the hollow injection molding method of the present invention is used. The method of controlling the deformation of the surrounding rock of the multiple-span mining roadway by the slurry anchor cable, the specific implementation steps are as follows:

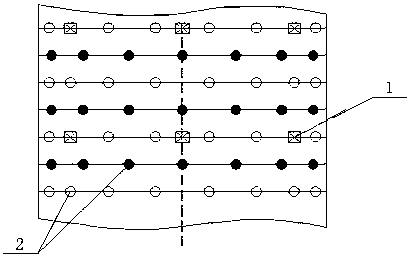

[0022] (1) Repair and expand the section 3 of the roadway. One month after the primary support and shallow hole grouting are completed, Φ22mm high-performance prestressed anchor rods 2 are used to strengthen the support of the 300m ahead working face in the roadway on the mining floor. , the row spacing is 800mm×800mm, all of which are arranged in the space of the primary support bolts, and the metal mesh 4 is laid on the entire section of the roadway at the same time, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com