Method for manufacturing super multi-core cable of super high-speed elevator

An elevator cable and a manufacturing method technology are applied in the manufacturing field of super-multi-core super-high-speed elevator cables, which can solve the problem that the U-shaped bending diameter of the cable cannot meet the requirements of high-speed running elevators, the vertical suspension torsion angle of the elevator cable is not large, and the cable control wire core Insufficient number and other problems, to achieve the effect of small torsion angle, large U-shaped bending diameter, and large number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

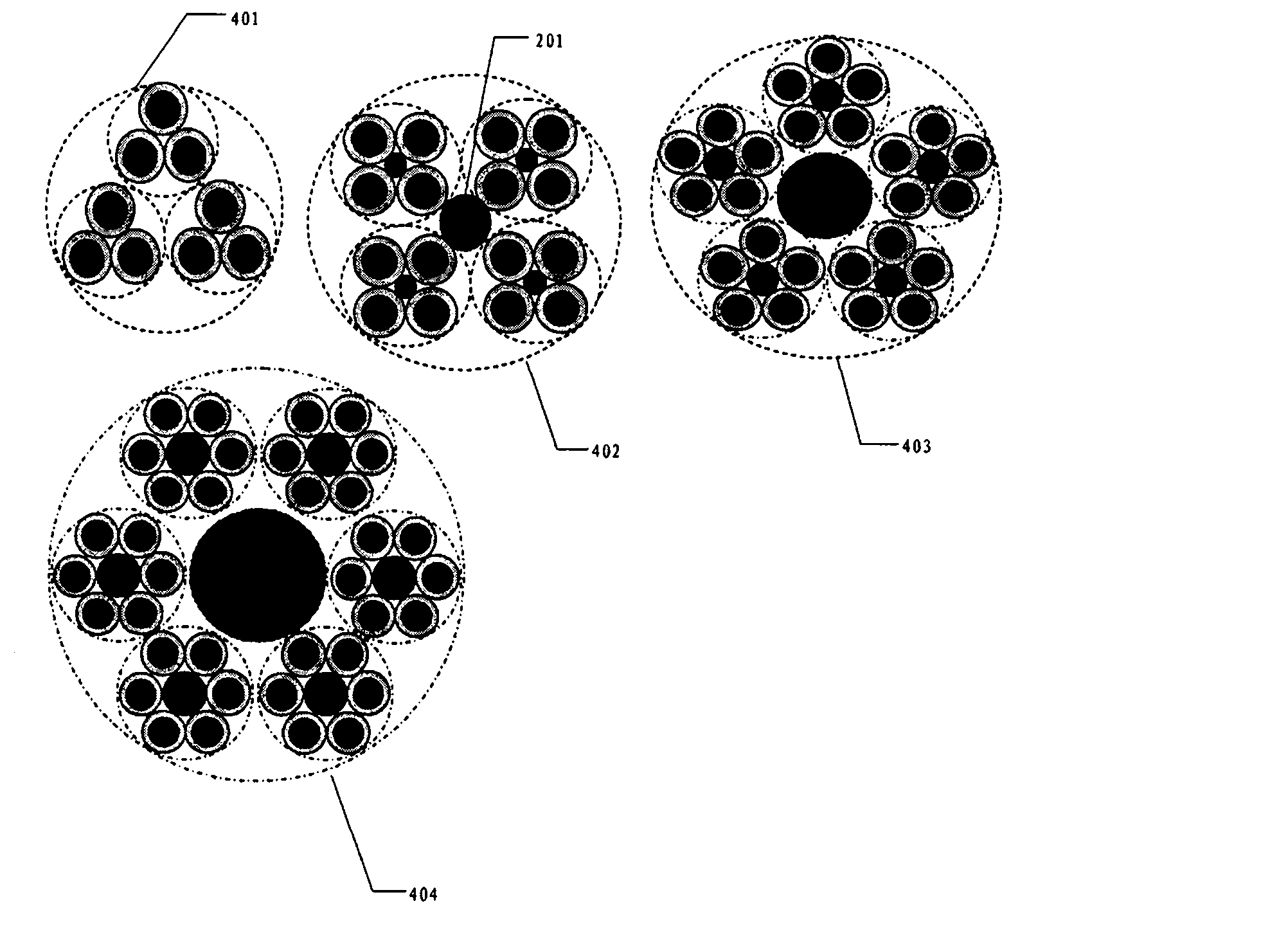

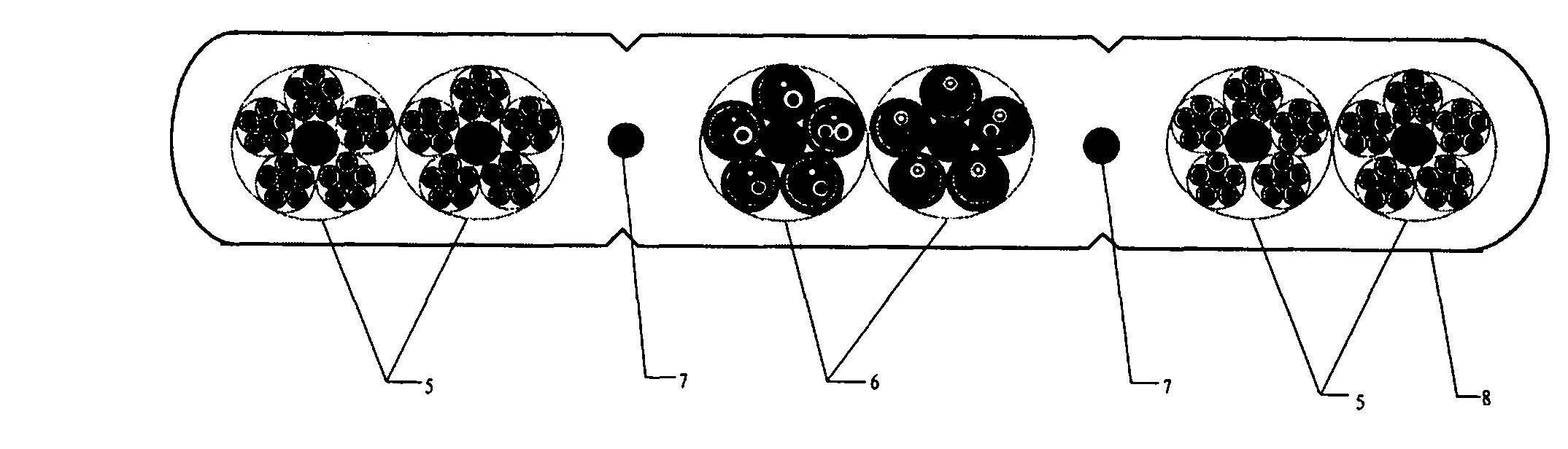

[0022] In order to solve the problems of less control wire cores of ordinary elevator cables, larger twisting angles of vertical suspension of cables, and smaller U-shaped bending diameters, the present invention proposes a manufacturing method such as Figure 4 The method shown for ultra-multicore ultra-high-speed elevator cables.

[0023] refer to Figure 4 , a kind of manufacture method of ultra-multicore ultra-high-speed elevator cable, it comprises the steps:

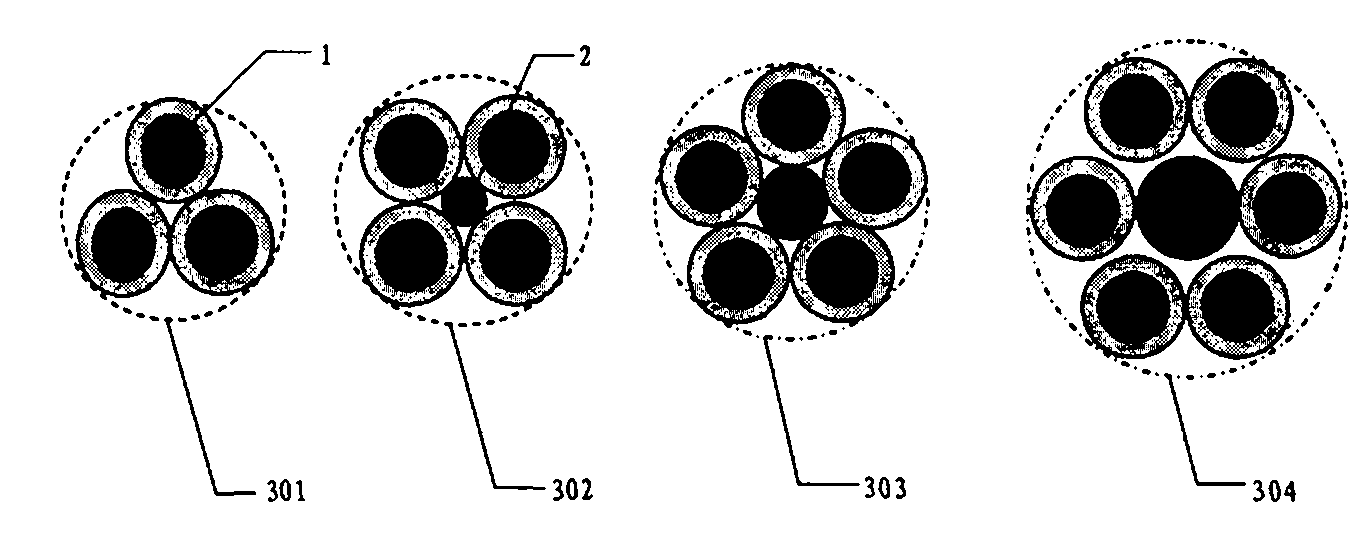

[0024] The first step, refer to figure 1 First, 3, 4, 5, or 6 insulated cable cores 1 are twisted into corresponding 3-core primary composite cable cores 301, 4-core primary composite cable cores 302, 5-core primary composite cable cores 303, Or a 6-core primary composite cable co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com