Assembling type inclined slow-adhesion pre-stressed concrete road surface structure

A technology of slow-bonding prestressed concrete pavement, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks. Area paving and other issues to achieve the effect of increasing driving comfort, saving steel consumption, and reducing road noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

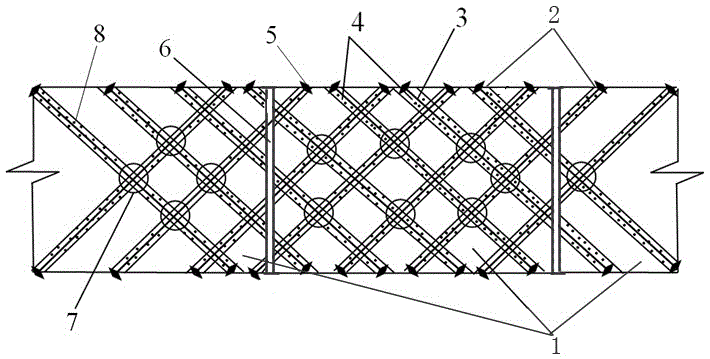

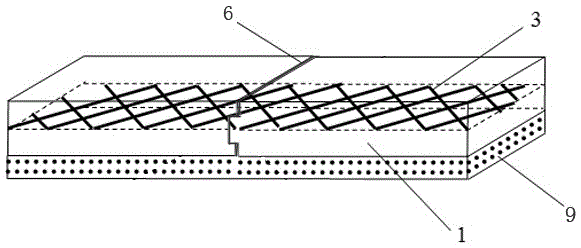

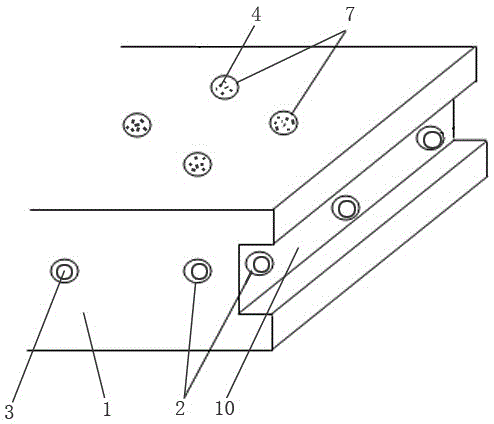

[0029] Such as figure 1 , 2 , 3 and 4, the assembled oblique slow bonded prestressed concrete pavement structure includes rubber water stop, CA mortar connection layer and anchor head, and it is composed of several prefabricated prestressed concrete pavement blocks 1 that are inserted into each other. The fitting positions of each side and the upper end surface of the prefabricated prestressed concrete pavement block 1 are respectively provided with a number of tunnel openings 2 and grouting holes 7, and through the tunnel openings 2, slowly bonded prestressed steel bars are inserted into the reinforcement tunnel 8. 3. Pour cement mortar from the grouting hole 7.

[0030] The above-mentioned insertion is the connection between the grooves 10 respectively provided on the adjacent surfaces and the matching convex keys 11 .

[0031] Above-mentioned splicing, its seam is provided with rubber waterstop 6.

[0032] The above-mentioned steel bar tunnels 8 are arranged vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com