Detergent storage and dropping device and roller washing machine

A detergent storage and drum washing machine technology, applied in the field of washing machines, can solve the problems of insufficient use of door body space, etc., and achieve the effects of easy maintenance, improved washing effect, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Such as Figure 6 to Figure 16 As shown, a detergent storage and dosing device of the present invention includes a first cavity 23 for storing detergent and having at least one opening, and a second cavity 24 for putting detergent and having at least one opening, The first cavity 23 communicates with the second cavity 24;

[0056] The second cavity 24 is also provided with a stirring device. The detergent in the first cavity 23 is put into the second cavity 24 and discharged after being stirred by the stirring device, and put into the washing tub of the washing machine.

[0057] Specifically, the first cavity 23 and the second cavity 24 are flat body cavity structures respectively, and the rear wall of the first cavity 23 is matched with the front wall of the second cavity 24 and arranged in close contact. Moreover, the stirring device also includes a stirring motor 251 arranged outside the second chamber 24, a stirring shaft arranged on the second chamber and penetrat...

Embodiment 2

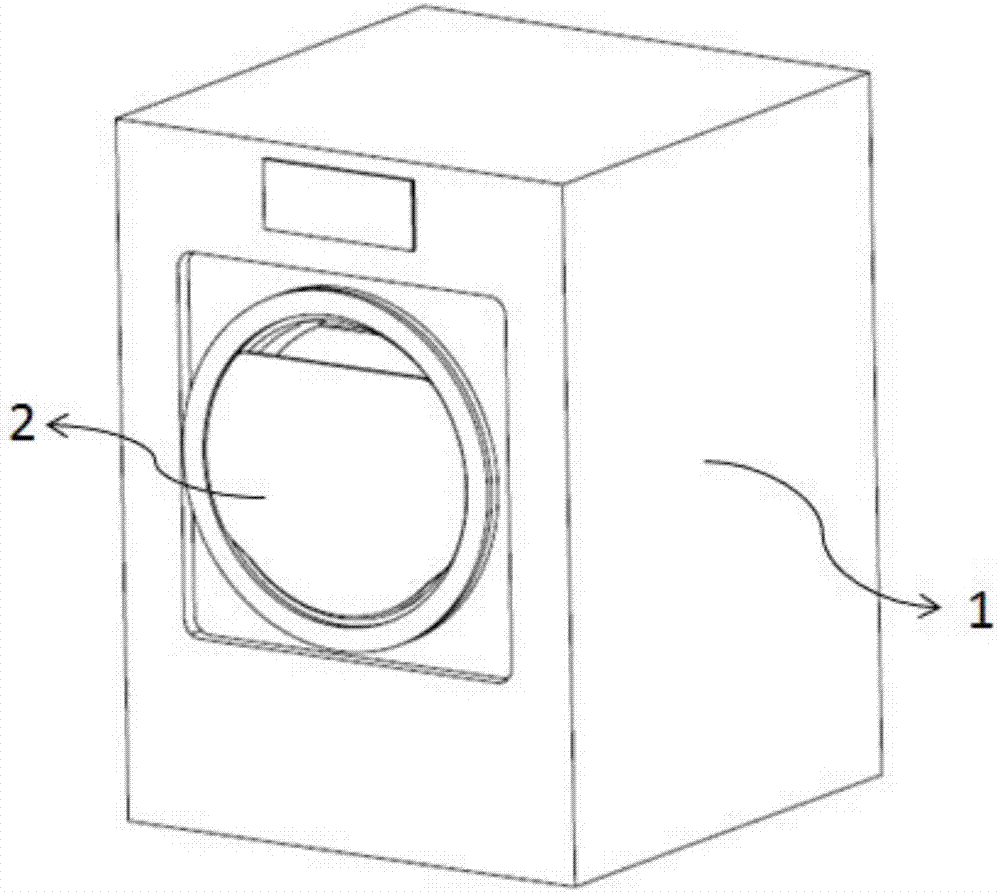

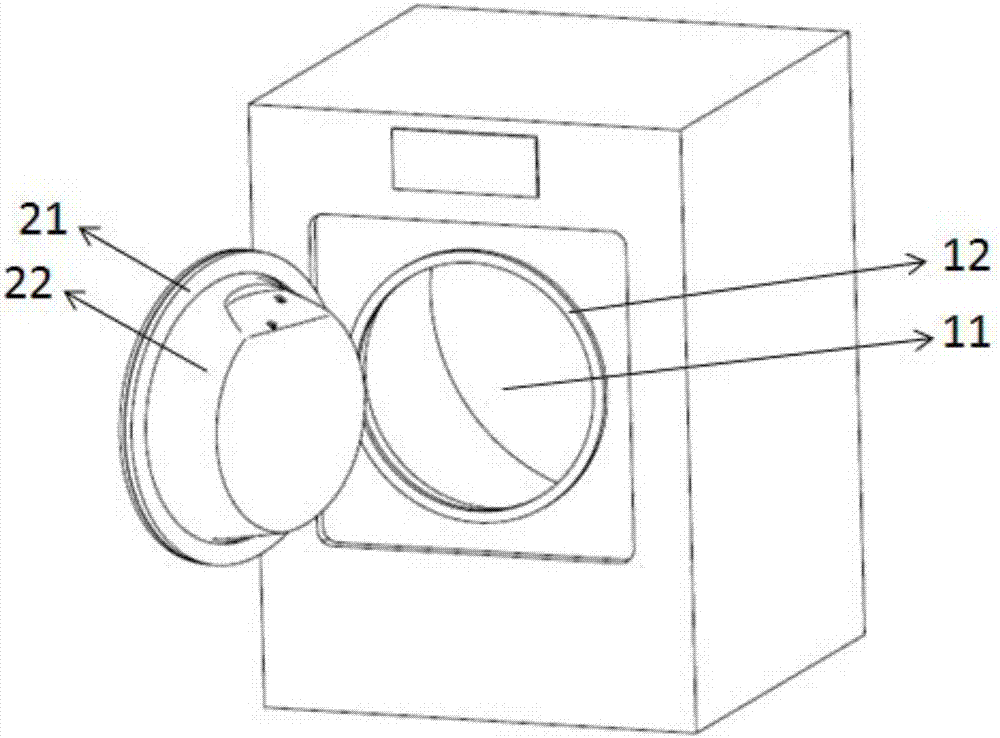

[0075] Such as Figure 1 to Figure 16 As shown, a drum washing machine 1 of the present invention includes a washing drum, a door body 2 and a glass bowl 22 arranged on the door body 2, the detergent storage and delivery device is arranged in the door body 2, and the detergent storage And throwing device throws detergent into the washing tub through the glass bowl 22.

[0076] Further, the first cavity 23 and the second cavity 24 are arranged in the door body 2 of the washing machine. Preferably, the second cavity 24 is arranged on the side of the door body 2 close to the washing tub.

[0077] Specifically, the inside of the drum washing machine 1 is provided with a washing drum, and the front side of the cabinet is provided with a door body 2 that can move axially. The glass bowl 22 is fixed on the door body 2 through the door seal, and the door body 2 drives the glass The bowl 22 moves axially. The door body 2 is matched with the insertion port 11 of the front-loading wash...

Embodiment 3

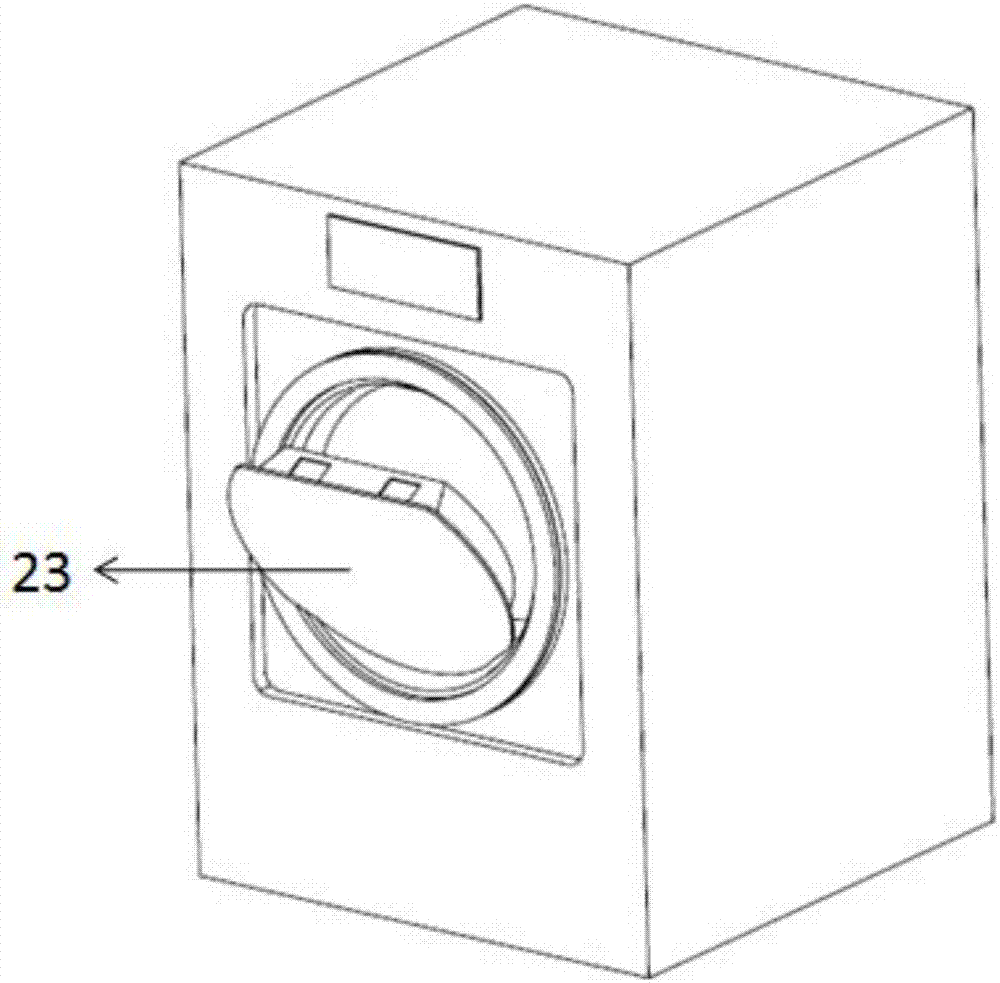

[0108] In this embodiment, a cavity is provided between the upper end of the first cavity 23 and the door body 2 of the drum washing machine 1, and the cavity can accommodate the space for the user to rotate the first cavity 23;

[0109] Preferably, the first cavity 23 is provided with a hand-holding portion toward the cavity, which is convenient for the user to rotate the first cavity 23 and add detergent into the first cavity 23 .

[0110] Alternatively, in this embodiment, the first cavity 23 is fixedly arranged in the glass bowl 22 of the door body 2, and the cabinet of the drum washing machine 1 is provided with a detergent liquid inlet and a liquid inlet pipe. One end of the liquid inlet pipe is connected to the liquid inlet, and the other end is connected to the liquid inlet of the first cavity 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com