A kind of high energy density supercapacitor and preparation method thereof

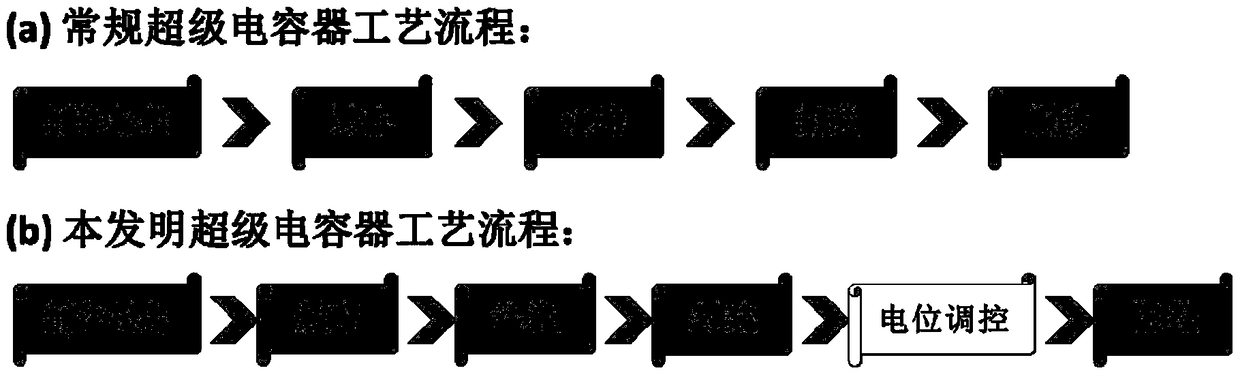

A supercapacitor, high energy density technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of insufficient utilization of the electrolyte voltage window and high specific capacity of the electrode material, and greater impact on the cycle life of the device. problems, to achieve the effects of increased energy density, ultra-long cycle life, and simplified operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

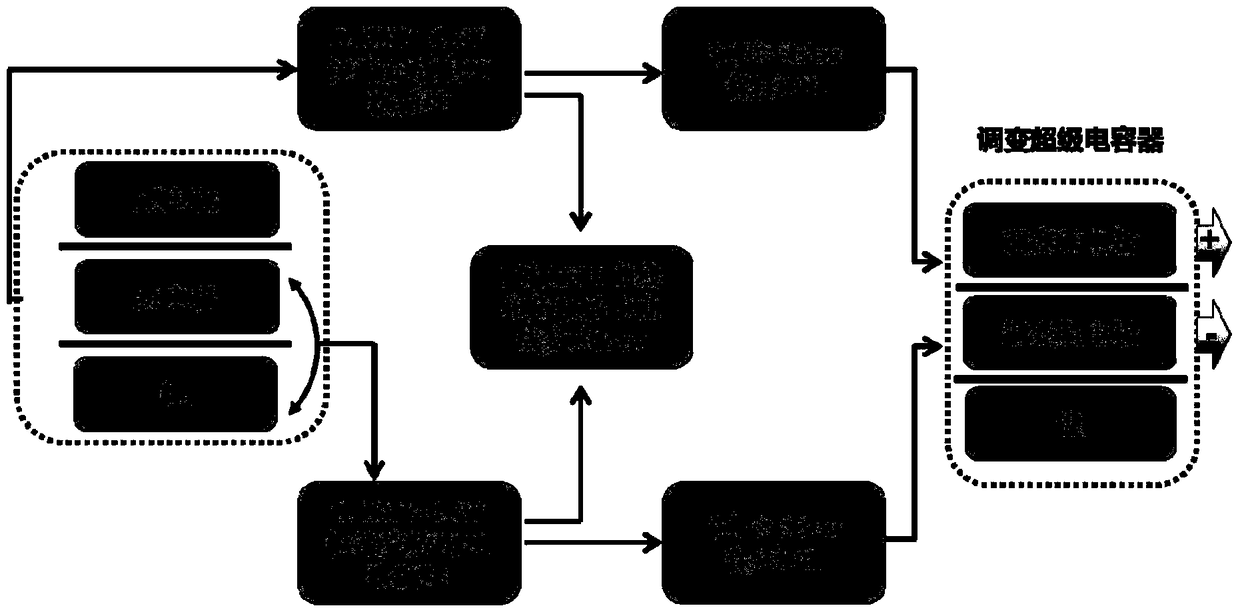

[0038] Regulate graphene as electrode material (oxygen content 6.5at%, specific surface area 412m 2 / g) and with LiPF 6 The ethylene carbonate / dimethyl carbonate solution is the process of the supercapacitor system of the electrolyte as follows:

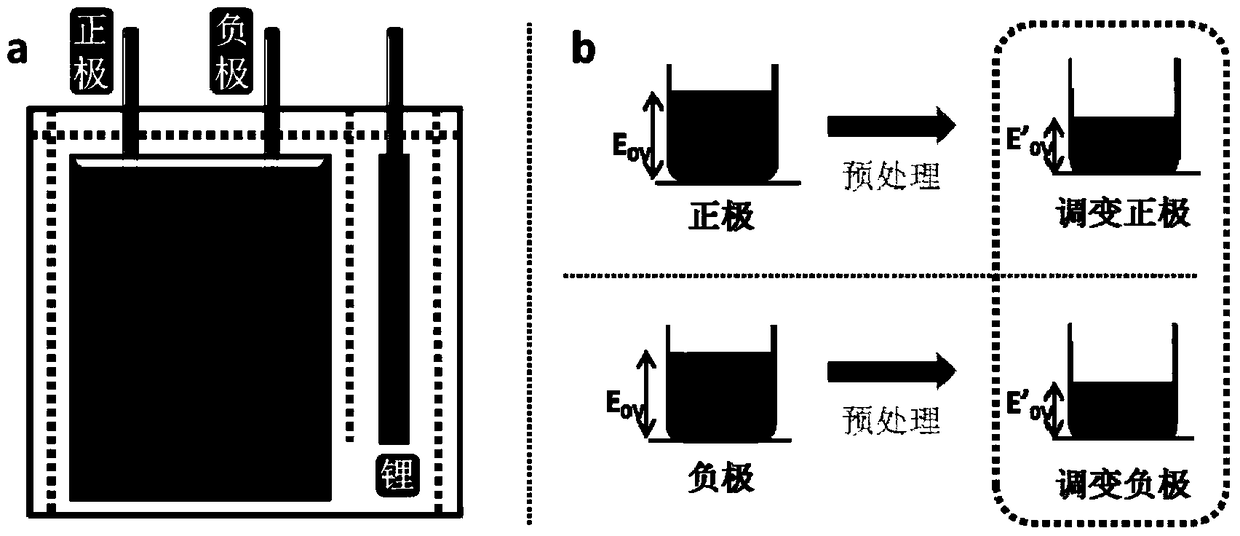

[0039] Graphene materials are used to make electrode sheets, and LiPF 6 Ethylene carbonate / dimethyl carbonate solution as electrolyte (where LiPF 6 The concentration is 1mol / L, the volume ratio of ethylene carbonate to dimethyl carbonate is 1:1), and it is used as positive and negative electrodes and lithium foil electrodes to assemble supercapacitor devices. The upper limit of the available potential window of the electrolyte is between 4.3V and 0.001V vs. Li, so that the positive and negative electrodes are charged and discharged at a constant current of 175mA / g with respect to the lithium electrode for 20 cycles respectively. Obtain the intersection point E'ov of the positive electrode discharge curve and the negative electrode...

Embodiment 2

[0044] Multi-walled carbon nanotubes (diameter2 / g, oxygen content 4.5at%) made into electrode sheet, with LiPF 6 Ethylene carbonate / dimethyl carbonate solution as electrolyte (where LiPF 6 The concentration is 1mol / L, the volume ratio of ethylene carbonate to dimethyl carbonate is 1:1), and it is used as positive and negative electrodes and lithium foil electrodes to assemble supercapacitor devices. The upper limit of the available potential window of the electrolyte is between 4.3V and 0.001V vs. Li, so that the positive and negative electrodes are charged and discharged at a constant current of 175mA / g with respect to the lithium electrode for 20 cycles respectively. Obtain the intersection point E'ov of the positive electrode discharge curve and the negative electrode charge curve. Then charge (discharge) the positive and negative electrodes to E’ov constant voltage for 12 hours at the same time. A modulated supercapacitor device is obtained.

[0045] Such as Image 6 ...

Embodiment 3

[0048] Single-walled carbon nanotubes (diameter2 / g, oxygen content 6.5at%) made into electrode sheet, with LiPF 6 Ethylene carbonate / dimethyl carbonate solution as electrolyte (where LiPF 6 The concentration is 1mol / L, the volume ratio of ethylene carbonate to dimethyl carbonate is 1:1), and it is used as positive and negative electrodes and lithium foil electrodes to assemble supercapacitor devices. The upper limit of the available potential window of the electrolyte is between 4.3V and 0.001V vs. Li, so that the positive and negative electrodes are charged and discharged at a constant current of 175mA / g with respect to the lithium electrode for 20 cycles respectively. Obtain the intersection point E'ov of the positive electrode discharge curve and the negative electrode charge curve. Then charge (discharge) the positive and negative electrodes to E’ov constant voltage for 12 hours at the same time. A modulated supercapacitor device is obtained.

[0049] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com