Telescopic ladder

A technology of telescopic ladders and telescopic rods, which is applied in the direction of ladders, buildings, building structures, etc., can solve the problems of high center of gravity, large space occupation, and occupancy, so as to enhance stability and use safety, save work space, reduce The effect of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

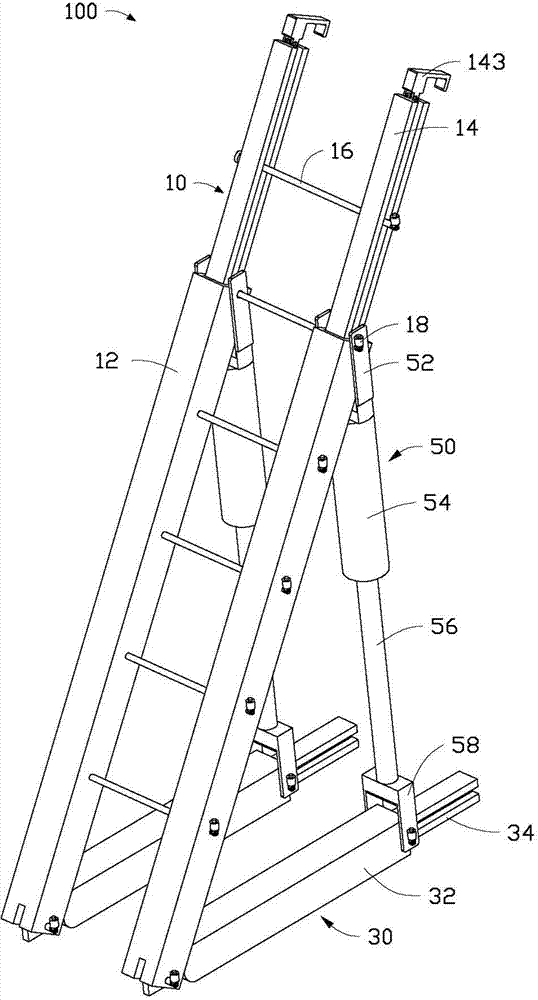

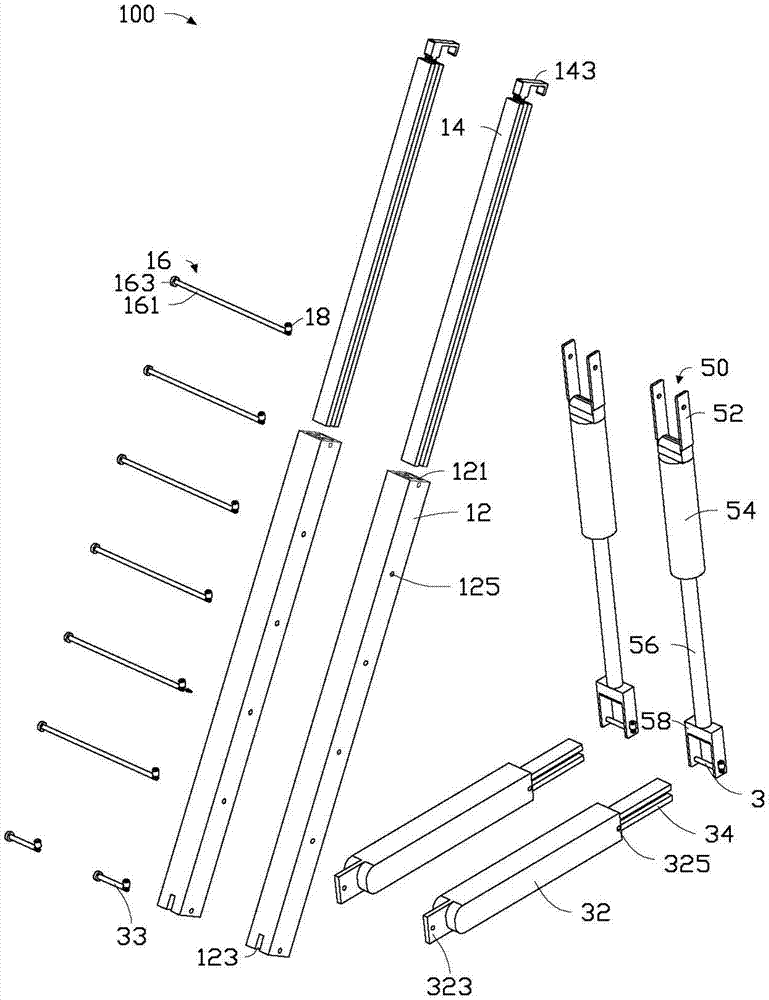

[0015] see figure 1 , the telescopic ladder 100 according to the embodiment of the present invention includes a ladder frame 10 , two base assemblies 30 disposed at one end of the ladder frame 10 , and two support assemblies 50 supported between the ladder frame 10 and the two base assemblies 30 . The ladder frame 10, the base assembly 30 and the support assembly 50 together form a triangular support structure.

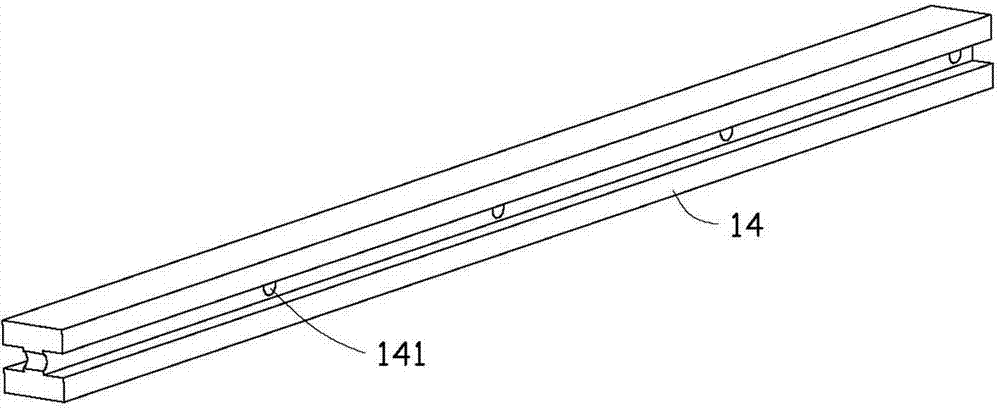

[0016] The ladder frame 10 includes two sleeve rods 12 arranged parallel to each other, two telescopic rods 14 accommodated in the two sleeve rods 12 respectively, and a plurality of transverse rods 14 straddling between the two sleeve rods 12 and the two telescopic rods 14. The rod 16 and the locking assembly 18 fixed on one end of the cross rod 16 .

[0017] Please also see figure 2 The sleeve rod 12 is roughly in the shape of a hollow rectangular rod, and a receiving groove 121 with a cross-section of "I" shape is opened in the axial direction, and the receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com