Semi-underground multiple-row lifting and transferring cubic garage

A technology of lifting and moving, three-dimensional garage, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of maximizing the area utilization rate, increase stability and use safety, and avoid direct force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

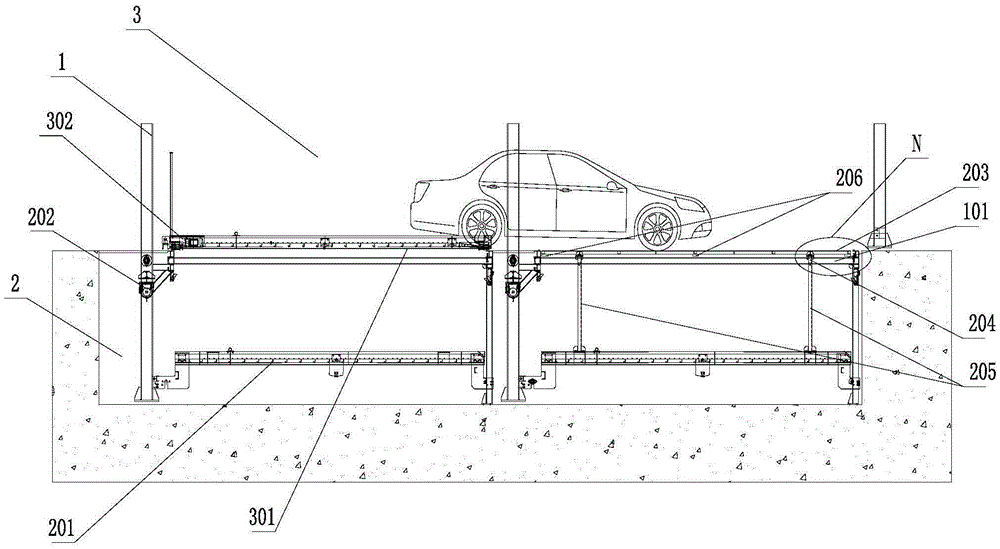

[0027] see figure 1 , a semi-underground multi-column lift-and-transfer three-dimensional garage, including a main frame 1 spliced by a plurality of support beams and columns, the main frame 1 is a multi-row multi-row berth including a pit layer 2 and a ground layer 3, Among them, the third berth on the ground floor is provided with a traversing vehicle-carrying plate 301 and a first traversing drive mechanism 302 for controlling the lateral movement of the traversing vehicle-carrying plate 301; The pit lifting drive mechanism 202 used to control the up and down lifting of the pit vehicle-carrying plate 201; the pit patch 203 is respectively provided on the support beams of the first row of berths on the pit floor 2, so that the rear row of vehicles can pass through the front row of pits. Access the car.

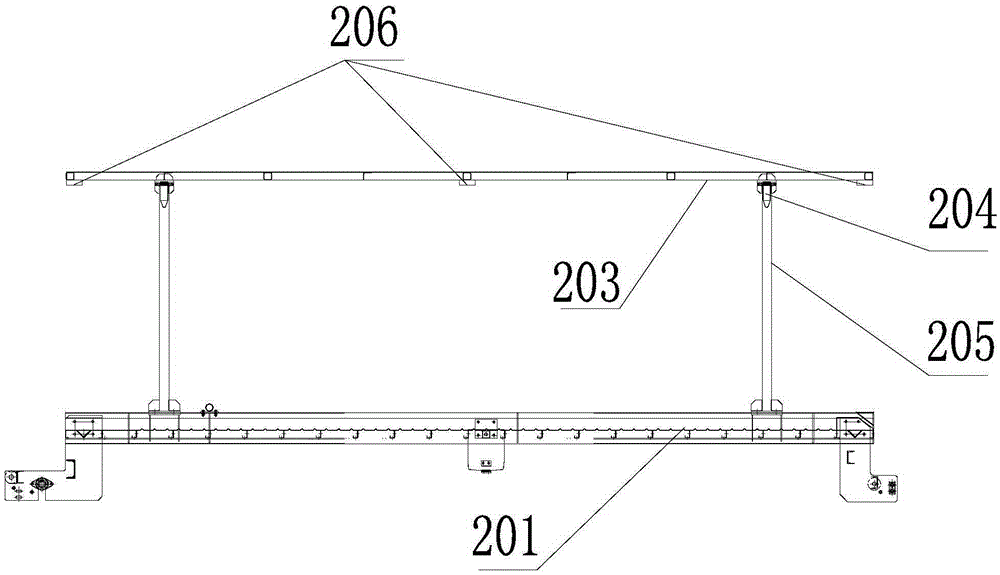

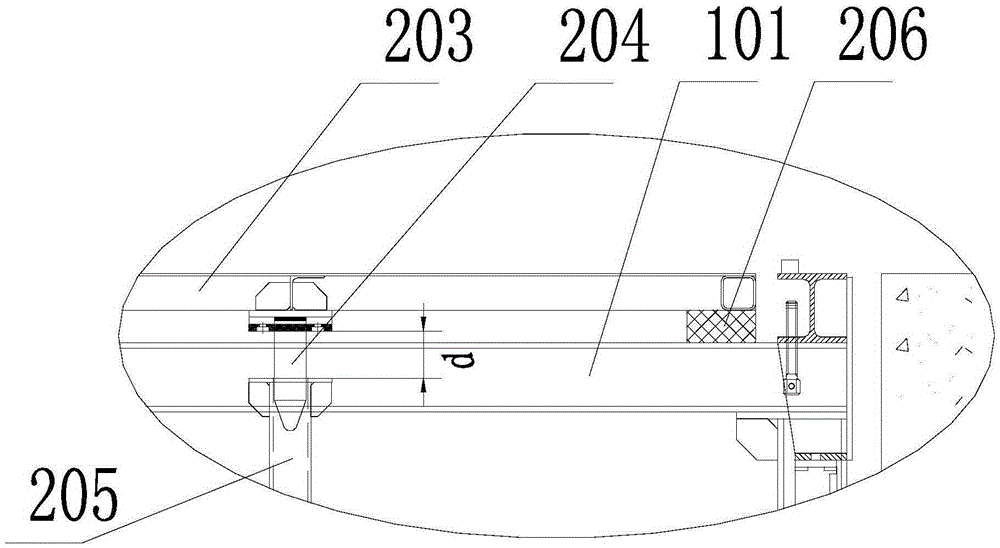

[0028] see Figures 2 to 4 , the pit patch 203 is arranged on the support beam 101 of the main frame 1, the pit patch 203 is provided with a connecting guide 204, and th...

Embodiment 2

[0035] see Figure 5 The difference between this embodiment and Embodiment 1 is that a second floor is also provided above the ground layer 3, and the berth on the second floor is provided with a lifting vehicle loading plate 400 and is used to control the lifting vehicle loading plate 400 to lift up and down. The lifting drive mechanism 500.

Embodiment 3

[0037] see Figure 6 The difference between this embodiment and Embodiment 1 is that several layers are arranged above the ground layer 3, including an intermediate layer 4 and a top layer 5, and the intermediate layer 4 berths are provided with a traversing trolley frame 401 placed on the traversing trolley. The first lifting vehicle loading plate 402 in the frame 401, the first lifting driving mechanism 403 and the second lateral movement driving mechanism 404, the first lifting driving mechanism 403 is used to control the first lifting vehicle loading plate 402 to lift up and down, and the second lateral movement The driving mechanism 404 is used to control the lateral movement of the trolley frame 401; the top floor 5 berth is provided with a second lifting vehicle loading plate 501 and a second lifting driving mechanism 502 for controlling the second lifting vehicle loading plate 501 to lift up and down.

[0038] The intermediate layer 4 consists of several layers. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com