Multi-axes synchronous hybrid device

A multi-axis linkage and hybrid technology, which is applied to large fixed members, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as small workspace, complex CNC programming, and strong motion coupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

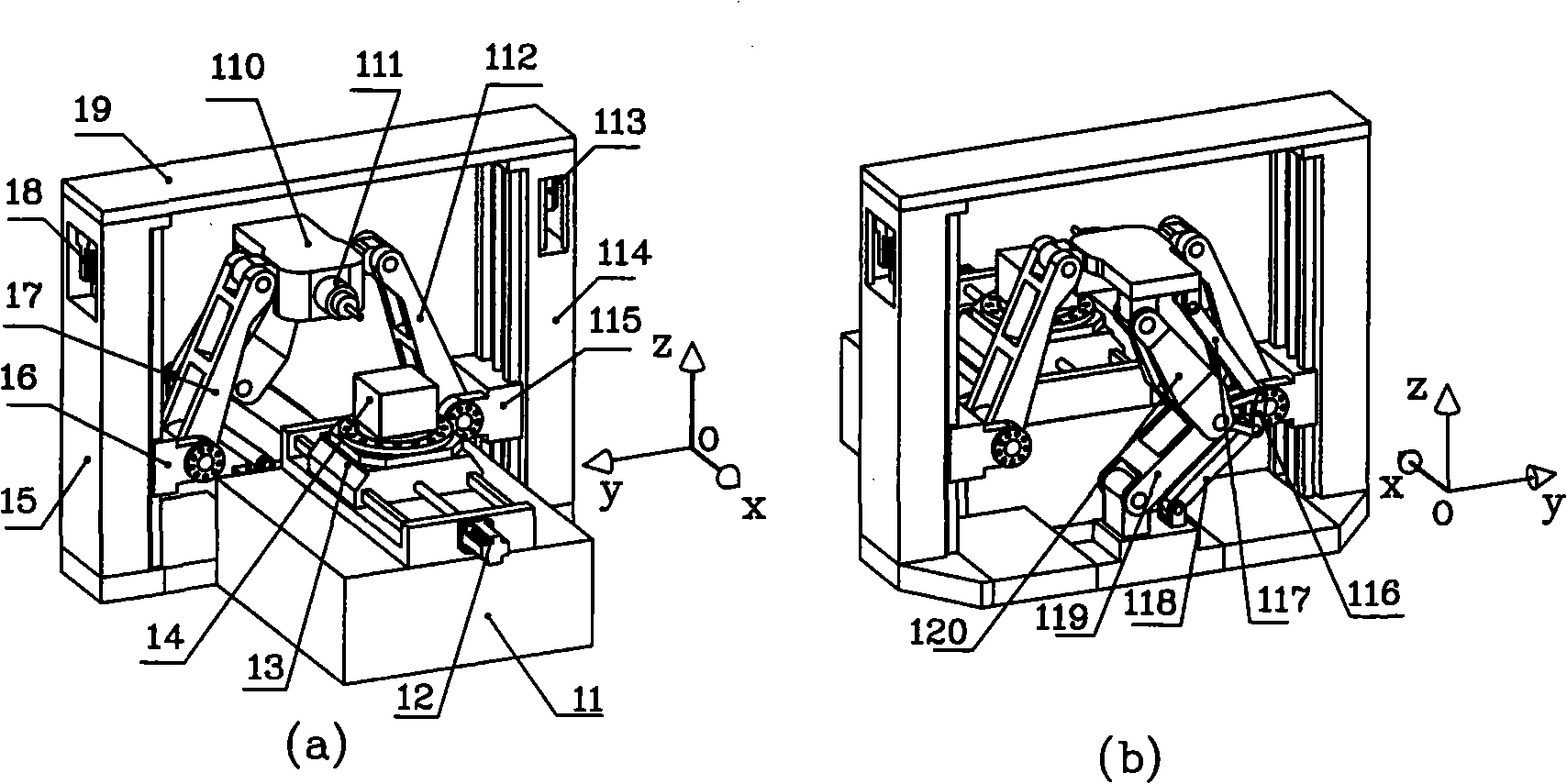

[0024] The structure of the multi-axis hybrid device in this embodiment is as follows: figure 1 shown, where figure 1 (a) is the front view, figure 1 (b) is a rear view, including the bed 11, the moving platform 110, the articulated swing head 111 for installing the main shaft, the workbench 13 for installing the workpiece 14 to be cut, and the symmetrical arrangement arranged on the bed and connected by a horizontal connector 19 The two columns 15,114 and the first, second, and third branch chains, the three branch chains are respectively connected between the columns 15,114, the bed 11 and the moving platform 110, and are connected to the column 15 , 114, the bed 11, and the moving platform 110 form a space parallel closed-chain mechanism, and the workbench 13 is driven by the servo motor 12 through a ball screw pair.

[0025] The first and second branch chains are PRR type motion branch chains, including the two columns 15, 114, a slider 16, a slider 115, a connecting rod...

Embodiment 2

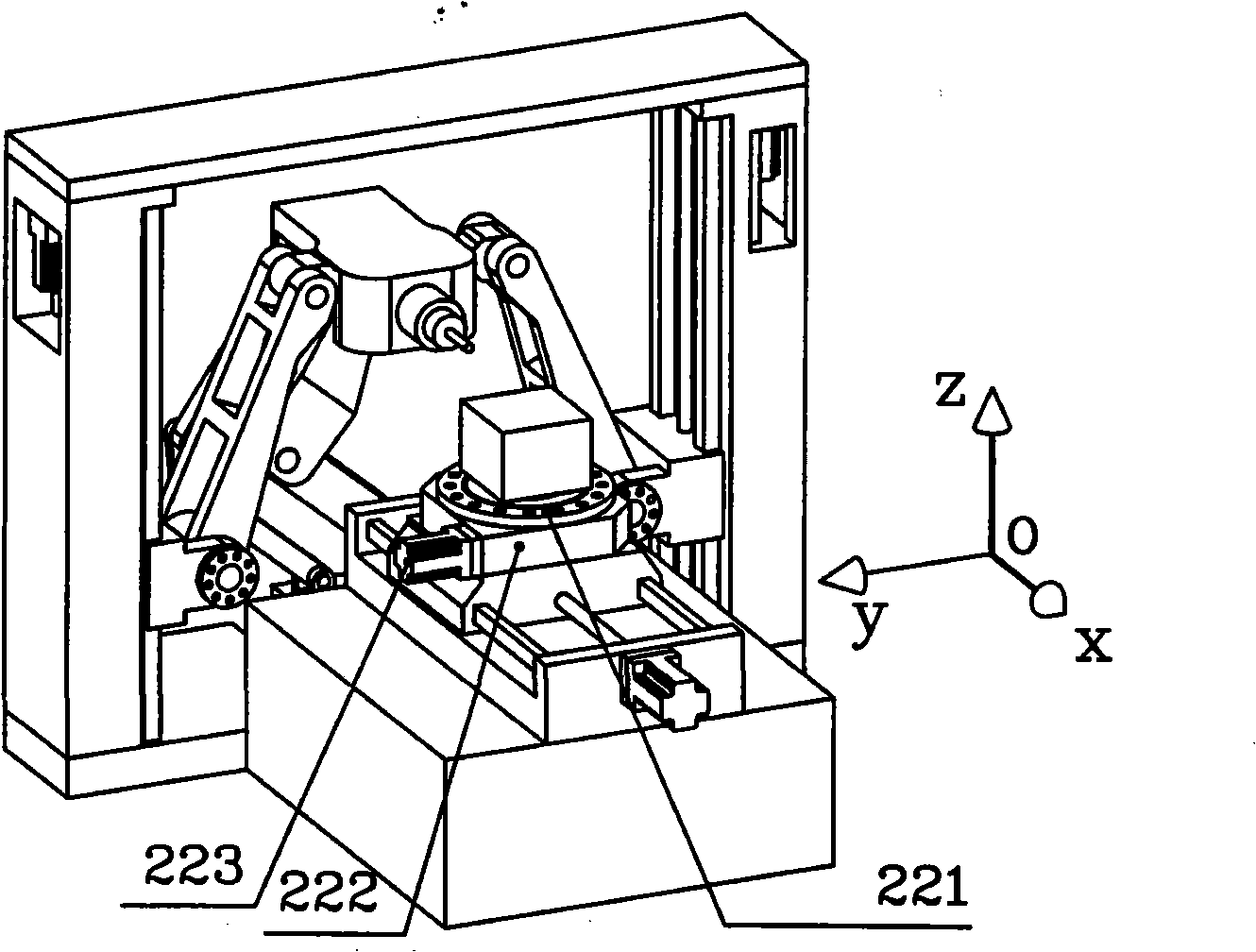

[0028] The structure of the multi-axis hybrid device in this embodiment is as follows: figure 2 As shown, the difference between this device and Embodiment 1 is that the worktable is composed of a platform 221 that rotates around the z-axis and a platform 222 that moves along the x-axis, and the platform 221 is driven by a servo motor 223 . The table has a degree of freedom of movement along the x-axis and a degree of freedom of rotation around the z-axis. Other structures and working processes of this embodiment are the same as those of Embodiment 1. The device realizes horizontal four-axis linkage control motion.

Embodiment 3

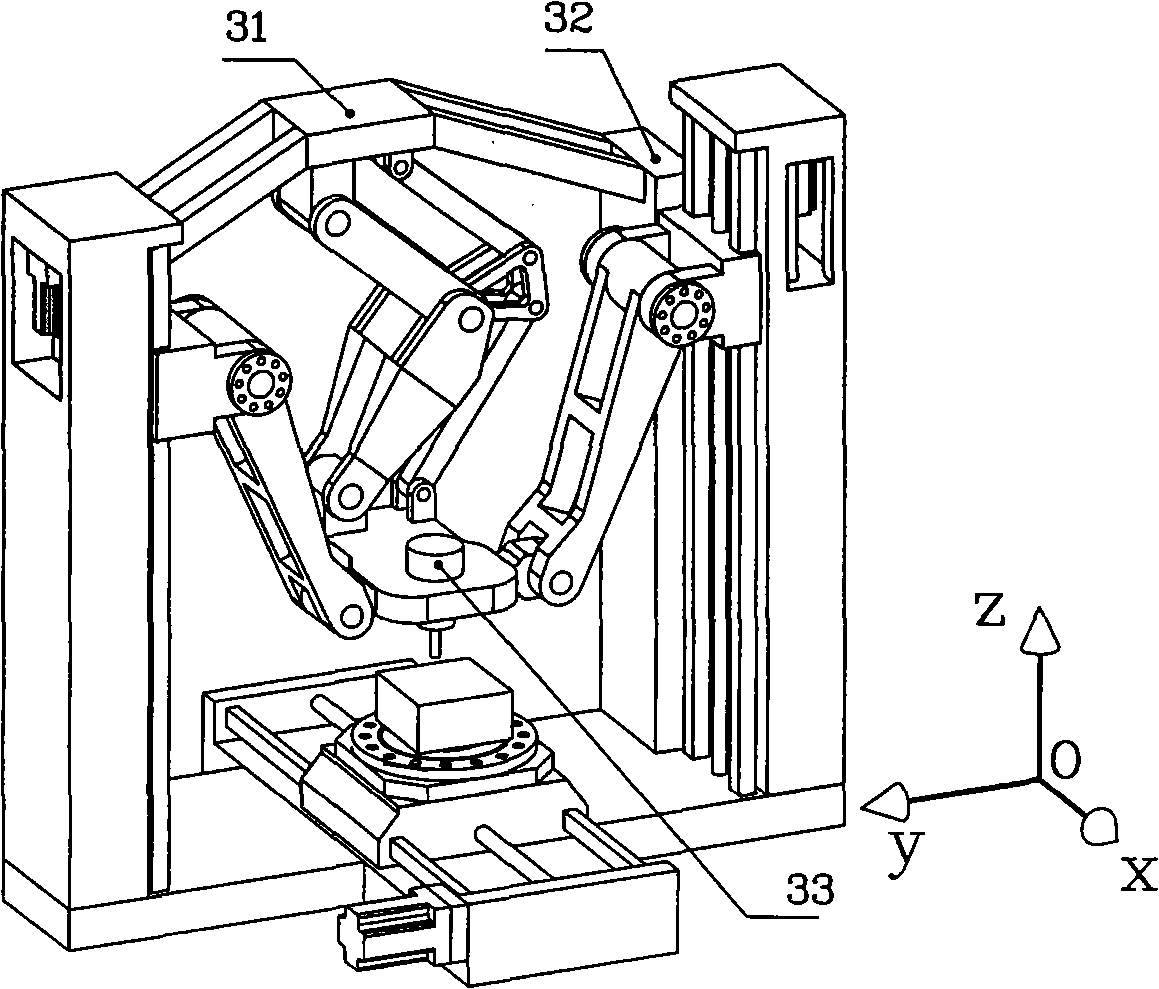

[0030] The structure of the multi-axis hybrid device in this embodiment is as follows: image 3 As shown, the difference between this device and Embodiment 1 is that the third branch chain is connected to the moving platform through the vertical extension 32 and the horizontal extension 31 of the bed, and the articulated swing head 33 is placed vertically, and is connected with the moving platform. The platforms are fixedly connected to form a vertical structure. Other structures and working processes of this embodiment are the same as those of Embodiment 1. The device can realize vertical three-axis linkage control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com