High-altitude board installation mechanical system

A mechanical system and board technology, applied in the field of high-altitude board installation mechanical systems, can solve problems such as difficulty in meeting large-scale board installation requirements, limited installation range, and robot self-healing, so as to improve installation work efficiency and safety, and large working space. , the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

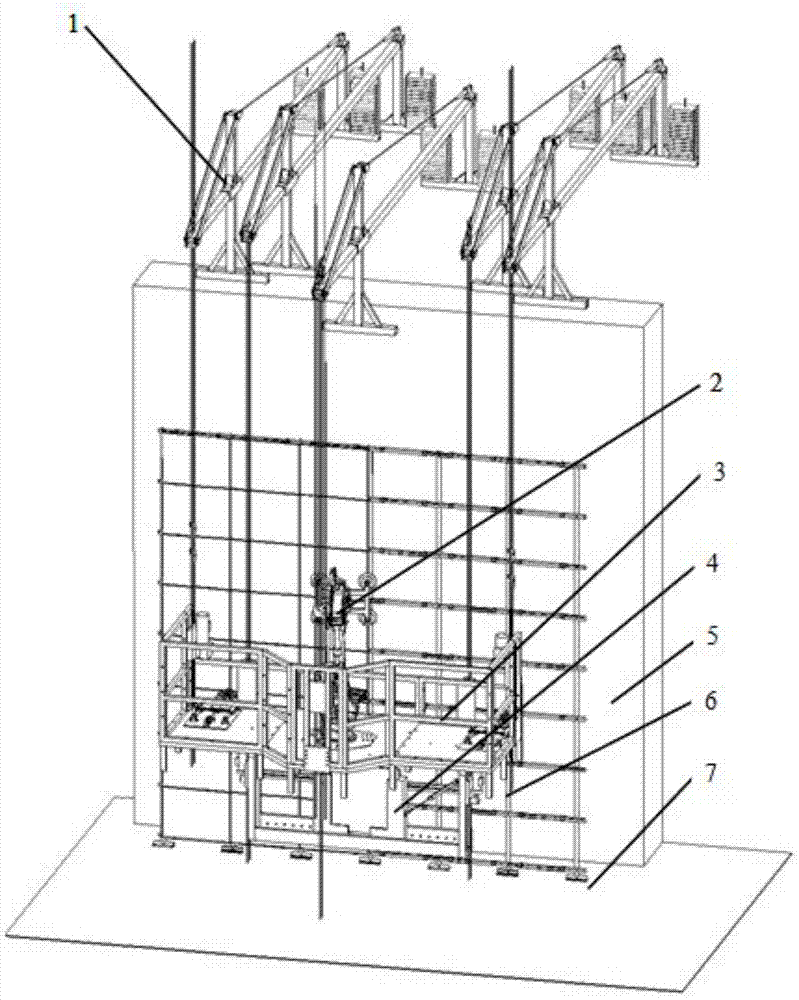

Embodiment 1

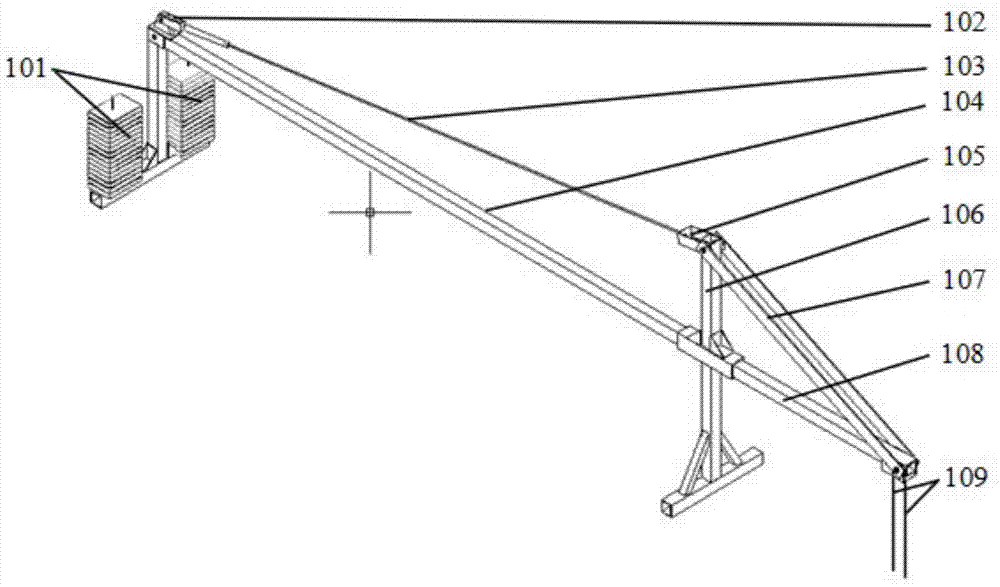

[0041] The present embodiment adopts the above connection method, wherein the length of the front beam 108 in the suspension mechanism 1 is 1460 millimeters; the length of the middle beam 104 is 6000 millimeters, and the height of the column 106 is 1000 mm; the front beam 108, the column 106 and the middle beam 104 are all Made of square steel pipe (100×100), with a thickness of 10mm and a cross-sectional area of 0.36e -2 m 2 ; The horizontal angle of the cable-stayed steel wire rope 103 is 28.1°, and the flexural modulus is 0.984e -3 , the moment of inertia is 0.492e -5 I y Swing arm type safety lock 110 is installed on the sling 109, this lock can automatically lock the sling and stop running, and can not reset automatically. The body 301 of the aerial work platform is 3900×1800×1600 mm in length, width and height, and it is built by welding and bolting with the material of round structural steel Q235. The aerial work platform 3 includes a platform body 301, a platform...

Embodiment 2

[0043] The connection and positional relationship of each part in the present embodiment are the same as embodiment 1, the difference is that the horizontal included angle of the cable-stayed wire rope 103 is 45 ° in the present embodiment, the length ratio of the length of the middle beam 104 and the front beam 108 is 3.5; The work platform 3 also includes a platform hoist mounting plate 303, the platform hoist 302 is fixed on the guardrail 3012 through the platform hoist mounting plate 303, the aspect ratio of the bottom plate 3011 is 3:1, and a main beam 30112 is attached to the bottom of the bottom plate 3011 (see Figure 9 ), the main beam 30112 extends from the vicinity of the edge of the bottom plate to the bottom of the manipulator mounting seat 3013, the projection of the main beam on the bottom plate and the projection of the suspension force point of the sling 109 on the guardrail 3012 on the bottom plate to the center of the installation seat ring 30132 The connect...

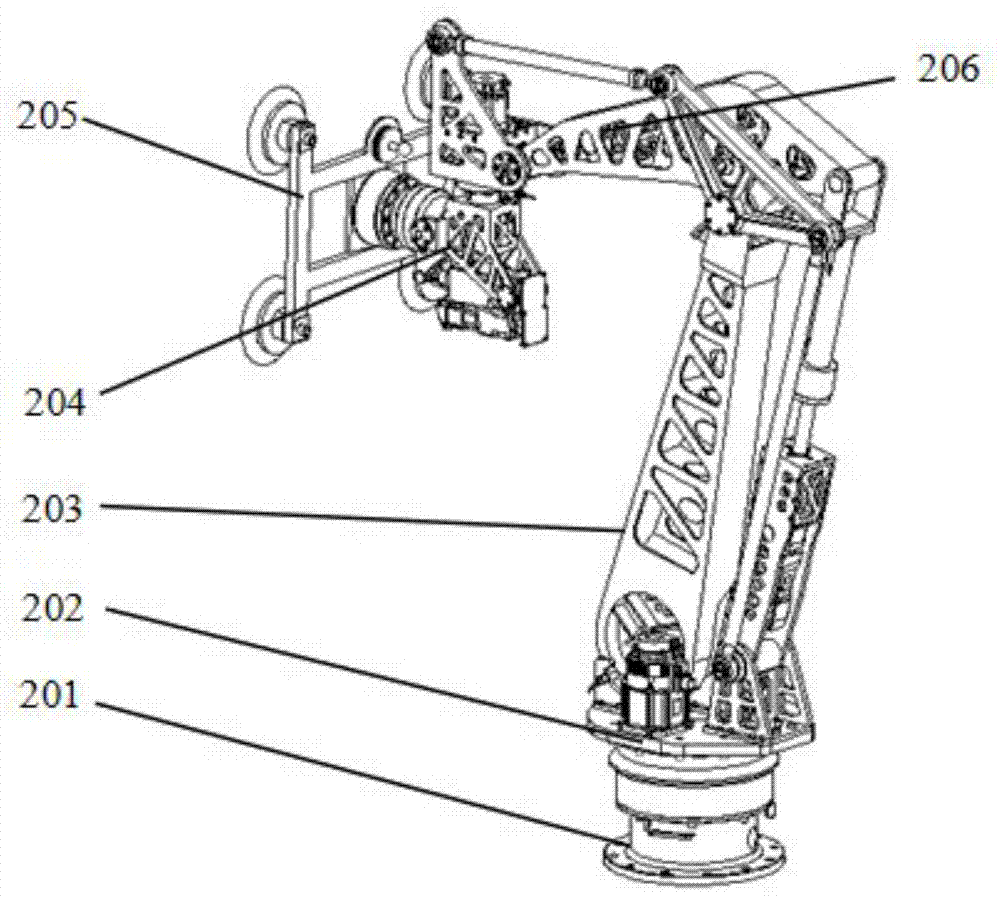

Embodiment 3

[0045] The present embodiment is the same as the connection and positional relationship among the embodiment 2, the difference is that the horizontal included angle of the cable-stayed wire rope 103 is 25 ° in the present embodiment, the length ratio of the length of the middle beam 104 and the front beam 108 is 4.5; the base plate 3011 The aspect ratio is 1.6:1. Both the robot arm 2033 and the robot forearm 2063 are made of hollowed-out plates, and the hollowed-out shape is triangular. The selection of the hollowed-out shape is based on the requirement of ensuring the strength and rigidity of the manipulator itself, and further reduces the weight of the manipulator itself. The end effector 205 includes a suction cup holder 2051, an actuator suction cup 2053 and a six-dimensional force sensor 2052. The shape of the suction cup holder 2051 is I-shaped, and one actuator suction cup 2053 is connected to each of the four corners of the I-shaped suction cup holder. One side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com