A single-line and double-line interchangeable intelligent beat assembly line system

An assembly line and rhythmic technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of production efficiency and product quality, small order quantity, time waste in finding accessories, etc., and achieve benefits to a wide range of Promote application, reduce initial investment cost, and apply to a wide range of industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

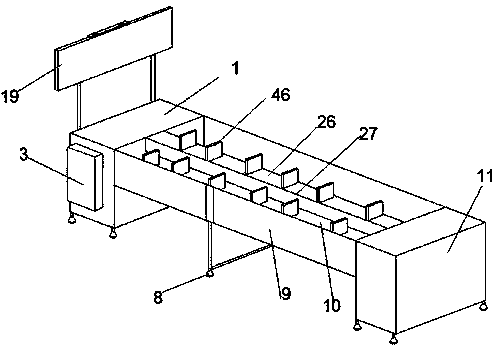

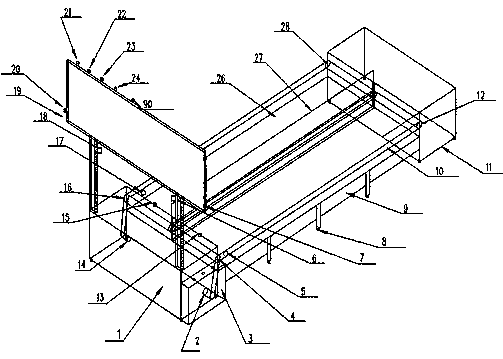

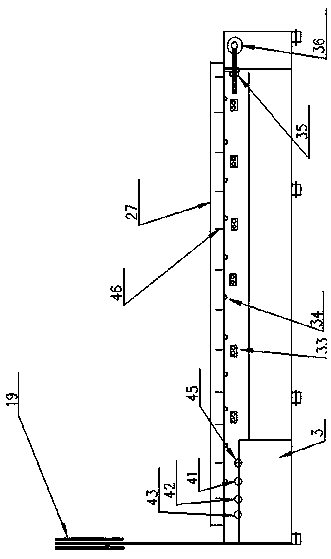

[0024] like Figure 1-6As shown, a single-line and double-line interchangeable intelligent rhythm assembly line system includes the main power frame 1 at the front of the equipment, the distribution box 3, the B-line drive motor 2, the A-line drive motor 14, the connecting frame 9 in the middle of the equipment, and the double-line The lifting partition 27 in the middle of the transmission belt, the rear frame 11 of the equipment, and the displays 19 on both front and rear sides. The equipment level adjustment feet 8 are equipped with support leg level adjustment nuts 57, the power distribution box 3 is installed on the front power main frame 1 of the equipment through bolts, and the front and rear displays 19 are installed on the front of the equipment through connecting rods. On the main frame 1 of the internal power, the front and rear dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com