Automatic assembling machine of LED (light emitting diode) socket adapter robot and working method thereof

A technology for LED sockets and automatic assembly machines, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low production capacity, easy fatigue and errors, and achieve the effects of saving labor, ensuring product quality, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

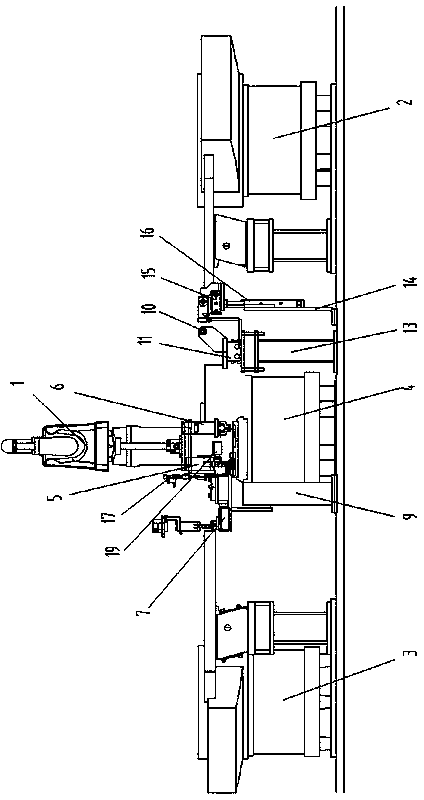

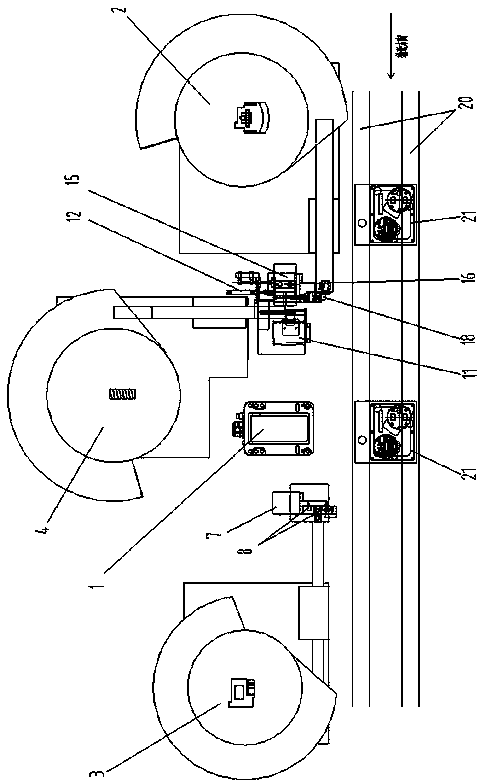

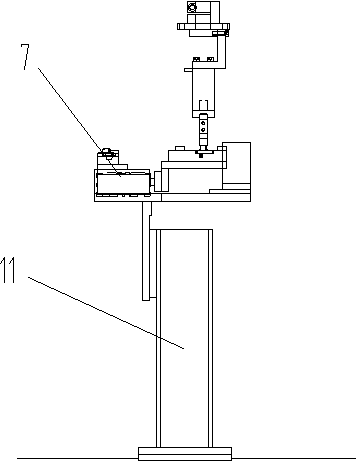

[0019] figure 1 , 2 , 3, 4, and 5 show the structure diagram of the equipment on the IV installation of the LED socket adapter robot automatic assembly machine / big green piece / big spring 2 pieces / small green piece station.

[0020] Robotic automatic assembly machine for LED socket adapter, the frame structure is based on the steel welded body, and it is set on the double-row endless conveyor belt with high conveying position accuracy on the frame body. The structure and layout are tightly and orderly designed, and the following processes are implemented. Arranged circularly in sequence: Manual loading station, I powder loading station 1, II powder loading station 2, III small spring installation station, IV large green parts / spring and small green parts installation station, V cover installation Work station, VI lock screw station, VII withstand voltage detection station, each station is effectively integrated on the double-row belt endless conveyor belt with high conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com