2R1T three degree of freedom space flexible precision positioning platform

A precision positioning, 2R1T technology, applied in the field of machinery, can solve the problems that cannot be achieved, high motion positioning accuracy, and the driving speed of the precision positioning mechanism is difficult to meet the speed requirements of the workbench of the lithography system, so as to achieve the effect of compact structure and elimination of nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

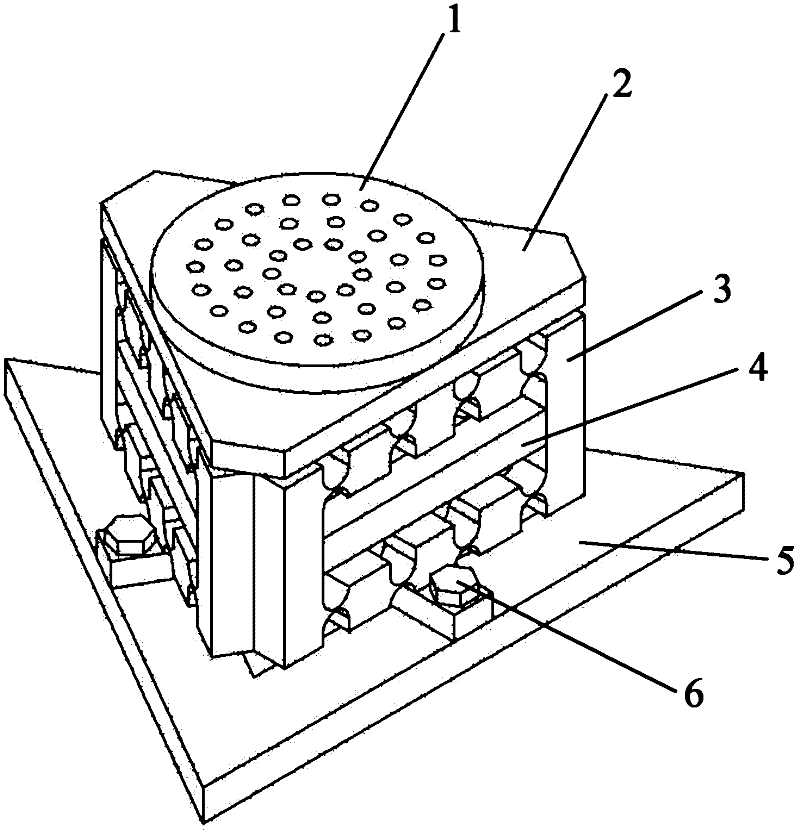

[0023] The 2R1T three-degree-of-freedom space flexible precise positioning platform (referred to as the positioning platform) designed by the present invention includes a moving platform 1 installed in sequence from top to bottom, a rigid end support frame 2, three rectangular branch chains 3, and three piezoelectric Ceramic driver 4 and a rigid base 5.

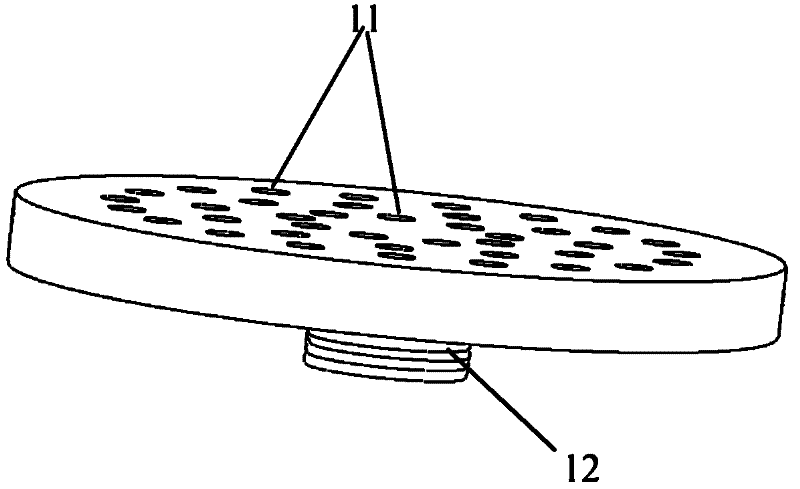

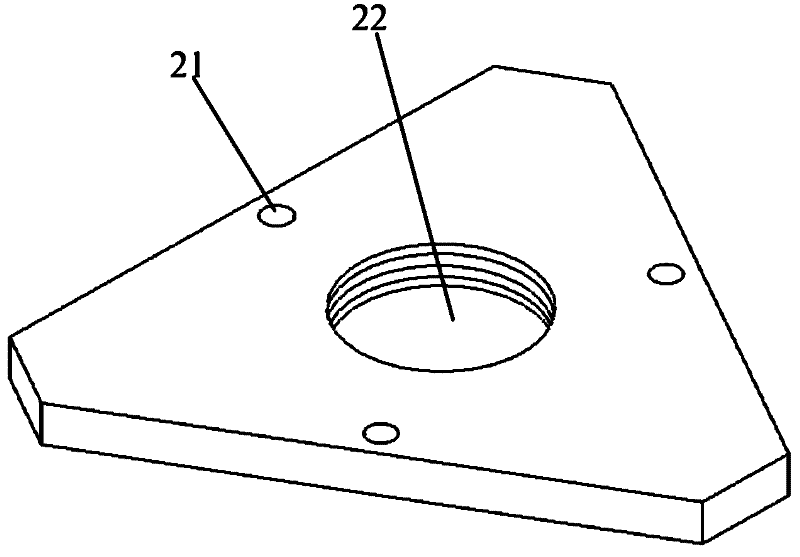

[0024] The moving platform 1 of the present invention (see Figure 1~3 ) is in the shape of an inverted boss, installed on the uppermost end of the positioning platform, a number of threaded holes 11 are opened on the large-diameter circular platform part of the moving platform 1, and the processing parts are fixed through the threaded holes 11, and the outer surface of the small-diameter cylindrical part of the moving platform 1 is processed There are threads 12 for rigid connection with the rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com