Medical thinprep clamp automatic assembly robot

An automatic assembly and robotic technology, applied in the field of medical machinery, can solve the problems of increasing the workload of medical staff, having no supply device for the base of the film clip, and reducing the efficiency of film production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

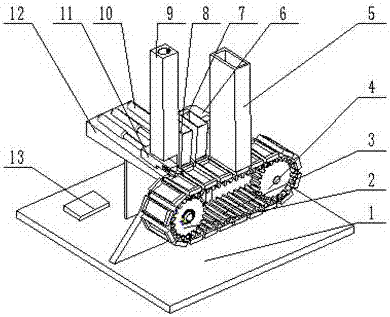

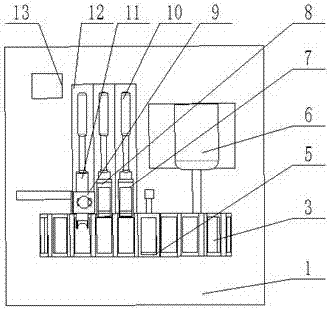

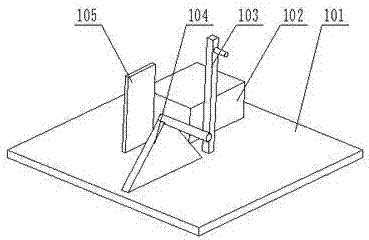

[0036] An automatic assembly robot for medical film-making clips is composed of a frame 1, a first gear set 2, a track set 3, a second gear 4, a base channel 5, a stepping motor 6, a first piece slot 7, and a second piece slot 8. The cylinder channel 9, the hydraulic cylinder 10, the push head 11, the hydraulic cylinder seat 12 and the controller 13 are composed. The controller 13 is installed on the frame 1, and the first gear set 2 is installed on the first gear of the frame 1. On the group fixed plate 104, the second gear 4 is installed on the stepping motor 6, and the stepping motor 6 is installed on the motor seat 102 of the frame 1, and the track group 3 is installed on the first gear set 2 and the second gear 4, The base channel 5 is installed on the base channel fixing plate 103 of the frame 1, the hydraulic cylinder seat 12 is fixed on the hydraulic cylinder seat fixing plate 105 of the frame 1, and the first slot 7 and the second slot 8 are fixed on the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com