Mine rock work technology

A process and rock technology, applied in the field of mine rock operation technology, can solve the problems of difficulty in maintaining the regular circulation of labor, the inability to guarantee the single entry level of rock roadways, and the occupation of many posts, so as to improve the drilling method, improve the blasting efficiency, improve the Effects of the Shipping Rock System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

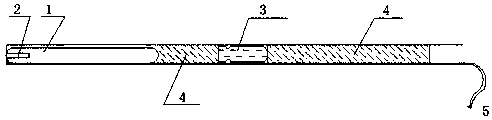

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] A mine rock operation process, comprising the following process steps:

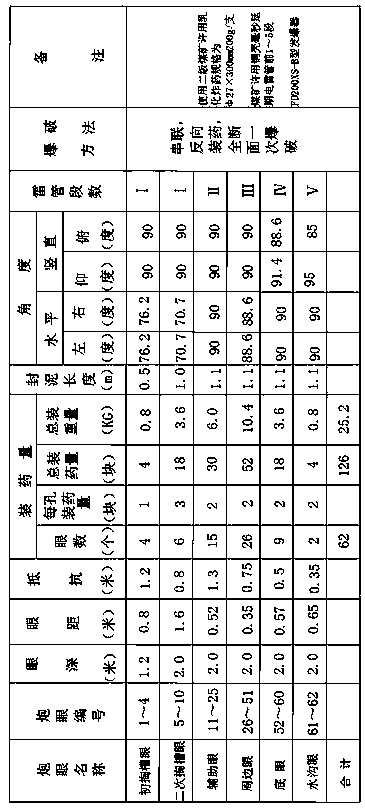

[0017] 1) Drilling process: hydraulic drilling rigs are used for drilling; through innovative practice, hydraulic drilling rigs are used to increase the blasting drilling speed, give full play to the advantages of equipment, shorten the absolute time occupied by drilling, and improve drilling efficiency. The two parts of the hydraulic drilling rig drill at the same time, the average working time for a single hole is 70s, and the drilling of the full section (taking 62 blastholes as an example) does not exceed 80 minutes (the time spent includes drilling, adjusting the drilling arm, moving the machine back and forth, etc. ), compared with three pneumatic drills drilling at the same time for 140 minutes, the work efficiency is improved by 43%.

[0018] 2) Blasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com