Self-moving loader for open-pit mining face

A self-moving and loader technology for surface use, applied in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of low operation efficiency and high production cost, and achieve the effect of improving work efficiency and saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

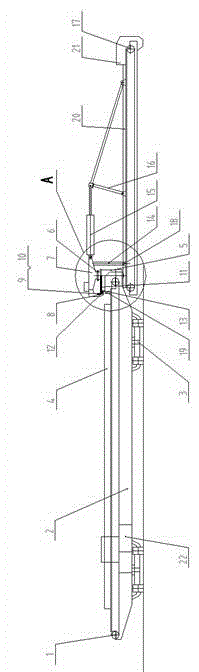

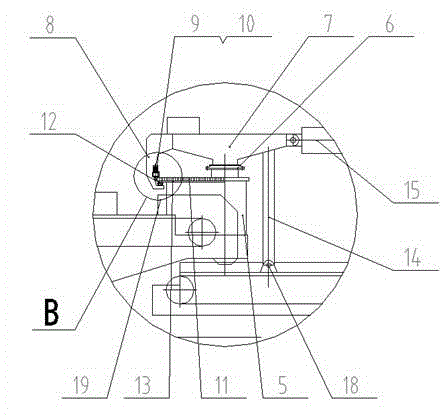

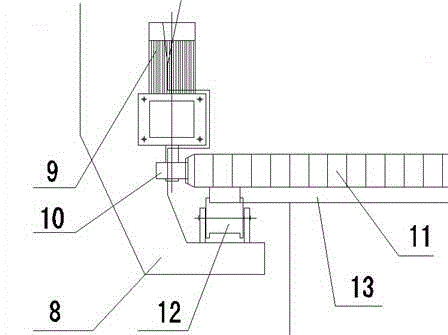

[0010] see figure 1 , it includes two belt conveyors arranged in front and back, wherein the rear is a material receiving belt conveyor 1 with a material receiving trough 4, the front is a discharge belt conveyor 17, and the discharge belt conveyor is The material-receiving end is placed under the reloading chute 19 of the material-receiving belt conveyor discharge end, and the material-receiving belt conveyor is installed on the support frame 2 with the walking crawler belt 3 . see figure 2 , the head of the support frame is provided with a steel structure platform 5, and a slewing support 6 is set between the steel structure platform and the column of the T-shaped frame 7, so that the steel structure platform and the T-shaped frame can rotate relatively, and the T-shaped frame is horizontal The left end of the bar is connected with a C-shaped arm frame 8, the right end of the T-shaped horizontal bar is hinged with one end of the hydraulic cylinder 15, the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com