Method for concrete conveying and lining construction in large-slope long inclined-shaft small-section tunnel

A construction method and concrete technology, which is applied in the direction of tunnel lining, shaft lining, tunnel, etc., can solve the problems of long process time, inflexible construction equipment, loose construction organization, etc., so as to speed up the speed of dismantling and erecting, improve the use efficiency and pouring speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

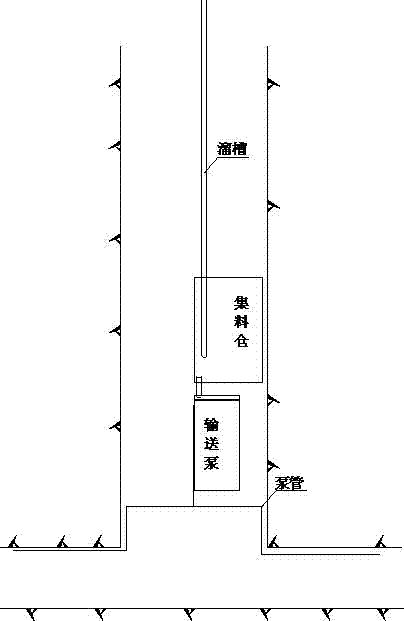

[0023] Such as figure 1 , the inclined shaft penetrates into the main tunnel from the side of the tunnel, the inclination angle of the inclined shaft is 17-24°, a chute is installed on the inclined shaft, and a concrete mixing system is installed near the top of the inclined shaft, and the mixed concrete enters the inclined shaft through the chute installed on the inclined shaft The collection bin at the bottom of the well, the collection bin is larger than 2.5m³, and a delivery pump and two delivery pump elbows are installed under the collection bin to transport the concrete to the pouring surface of the upper and lower sections of the tunnel. The horizontal transportation slope in the tunnel is -0.24% to 0.24 %, it can achieve up to 1.4km downhill pumping relay transportation, and the maximum distance of a single pump relay can reach 640m. In order to ensure the smooth flow of the trackless transportation channel, a place with a relatively large section is selected as the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com