Method for disassembling LCD display panel

A liquid crystal display, panel technology, applied in the direction of instruments, optics, manipulators, etc., can solve problems such as large movement range, shorten the time, and improve the speed of disassembly and investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

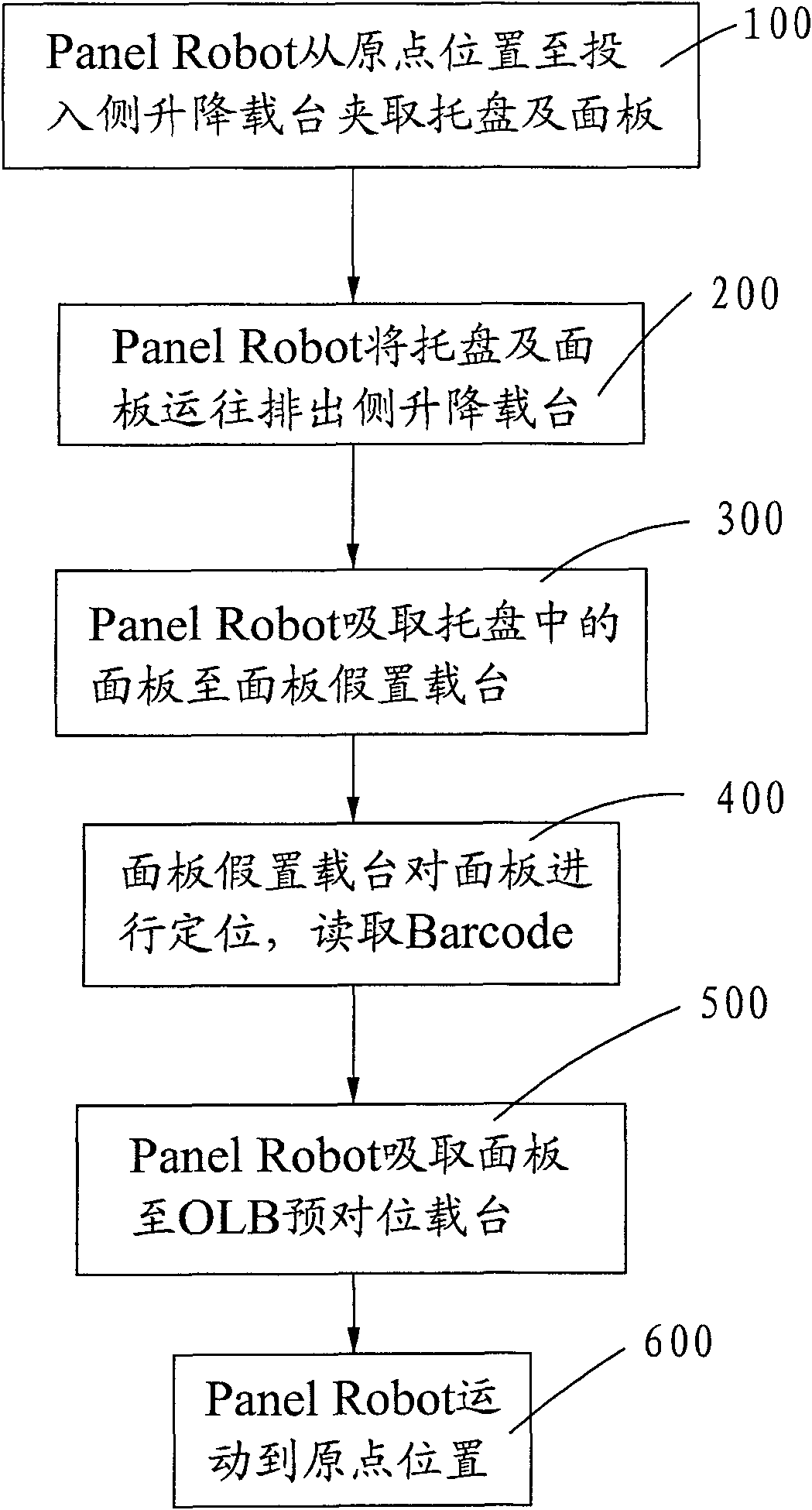

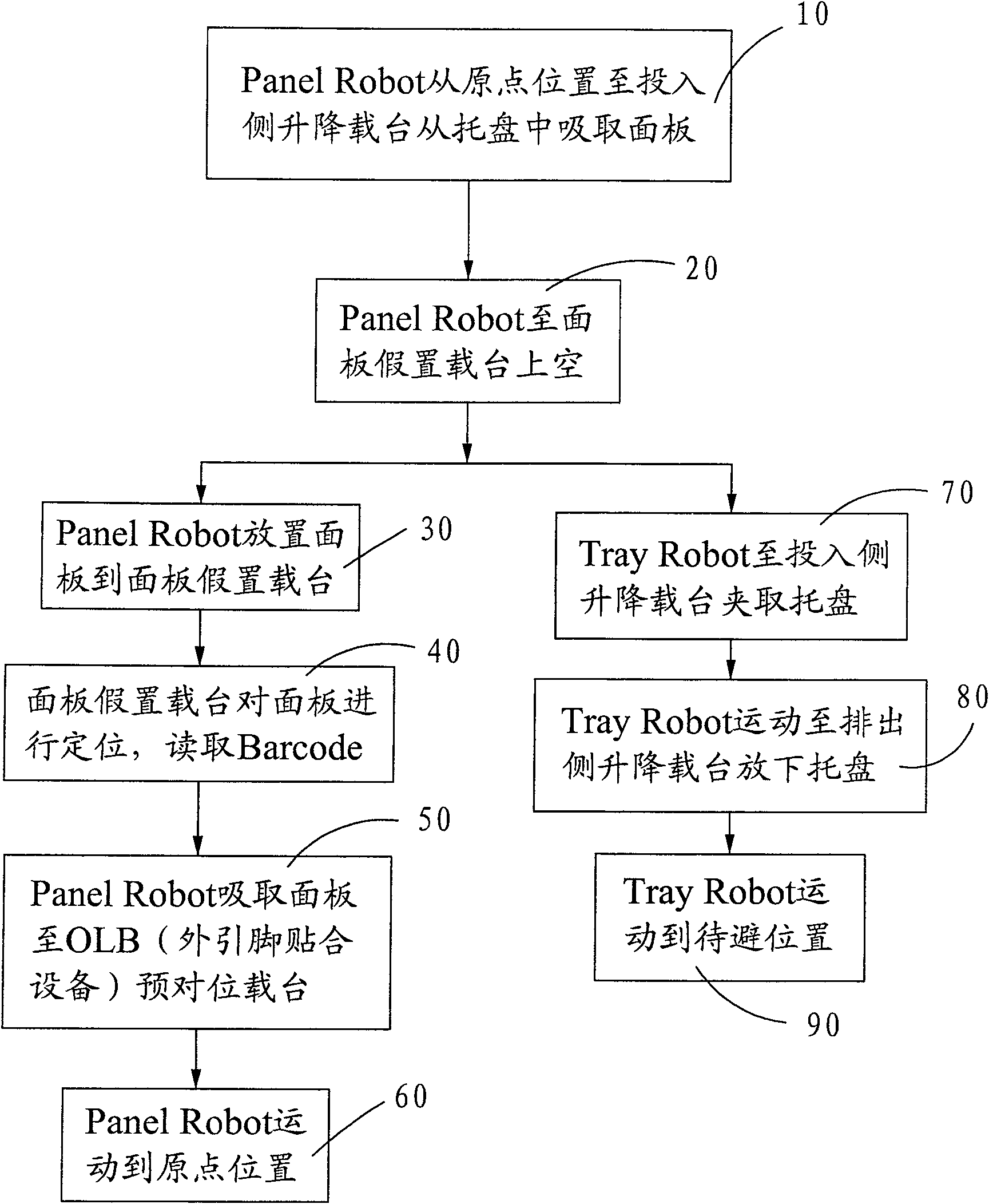

[0020] see figure 2 As shown, compared with the prior art, the present invention adds a Tray Robot to work at the same time, mainly responsible for tray discharge. Specific steps are as follows:

[0021] Step 10: The Panel Robot lifts the carrier from the origin position to the input side to pick up the panel from the tray;

[0022] Step 20: Panel Robot goes to the space above the panel dummy carrier;

[0023] Step 30: Panel Robot places the panel on the panel dummy carrier;

[0024] Step 40: Place the panel on the stage to position the panel and read the Barcode;

[0025] Step 50: The Panel Robot picks up the panel to the OLB pre-alignment carrier;

[0026] Step 60: Panel Robot moves to the origin position;

[0027] While performing step 30, Tray Robot performs the following steps 70 to 90 in sequence;

[0028] Step 70: The Tray Robot grabs the tray from the evacuation position to the lifting platform on the input side;

[0029] Step 80: The Tray Robot moves to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com