Turning mechanism of consecutive mining tractor

A tractor and mine-used technology, which is applied in the field of turning mechanism of mine-used continuous tractors, can solve the problems of increased transportation links, large number of personnel, and low transportation efficiency, and achieves easy installation, simple structure, improved transportation efficiency and transportation safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

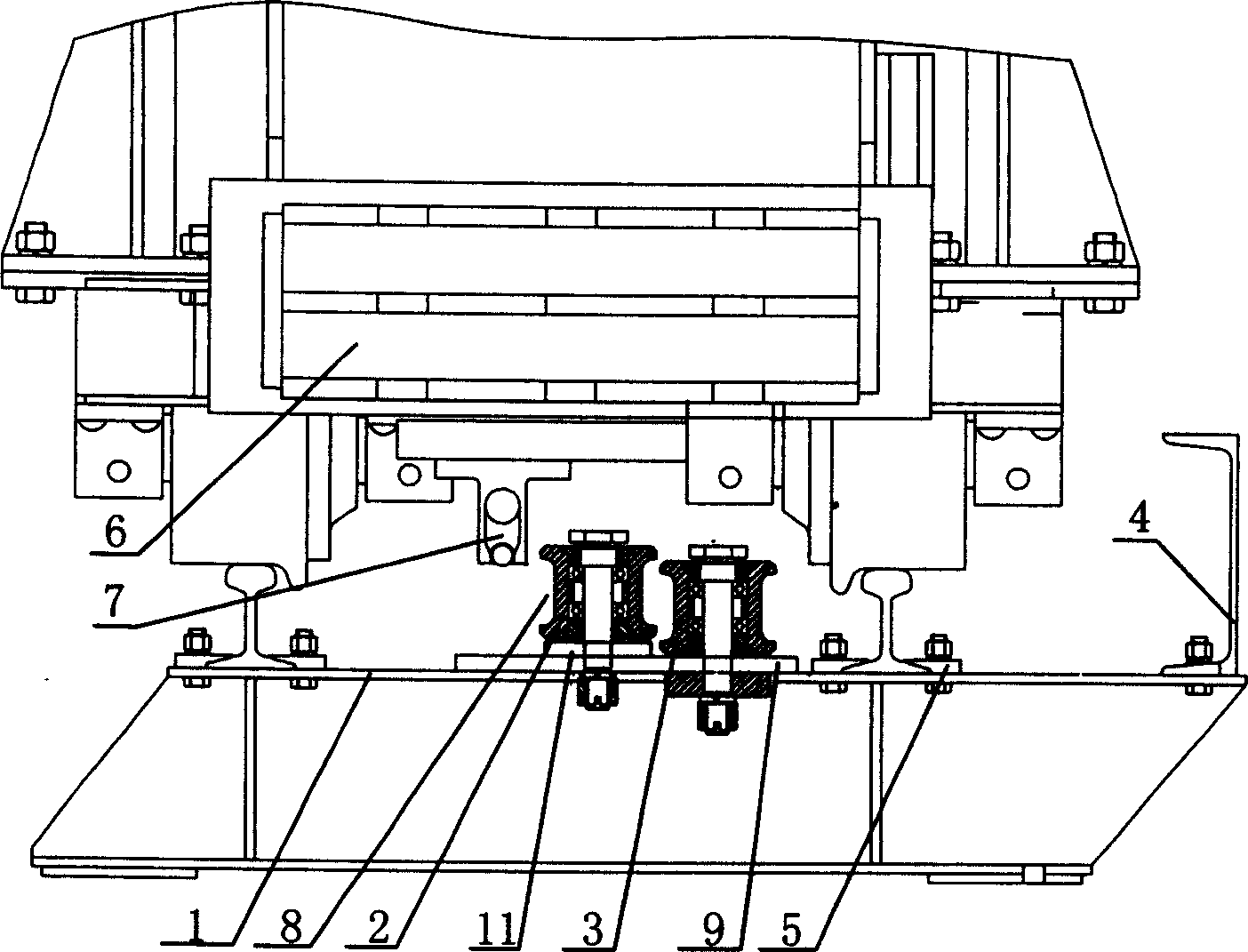

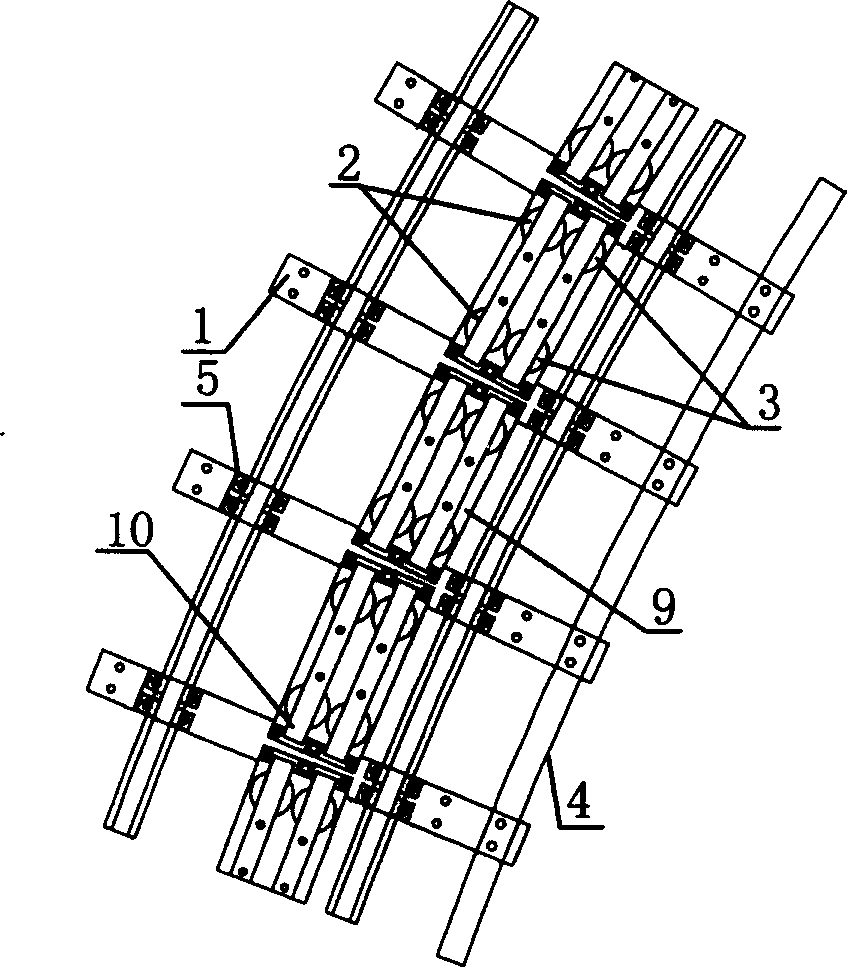

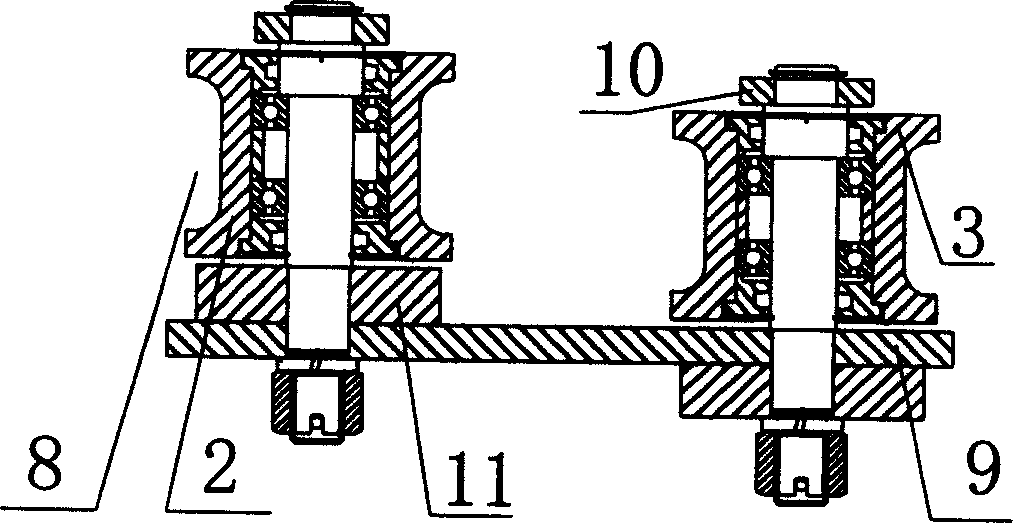

[0011] A turning mechanism of a mine-used continuous tractor, comprising an underframe 1 provided with a ground anchor hole, the underframe 1 is fixed with a main rope curve steering wheel 2 and an auxiliary rope curve steering wheel 3, and the main rope curve turns The surface of wheel 2 and auxiliary rope curve steering wheel 3 has a positioning rope groove 8. Have axle hole on the bottom frame 1, the wheel axle of main rope curve turning wheel 2 and auxiliary rope turning wheel 3 passes through axle hole, and fixes with nut. In order to make the product more integrated, the turning mechanism of the present invention also includes a fixing plate 9 for fixing the main rope curve turning wheel 2 and the auxiliary rope turning wheel 3, so that the main rope turning wheel 2 and the auxiliary rope Curve steering wheel 3 forms a wheel set, which is more convenient for installation.

[0012] During specific installation, the turning mechanism of the present invention is fixed alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com