Time-sharing transporting and filling system for underground coal and waste rock

A technology of gangue and gangue bin, applied in the field of gangue transportation and filling system, can solve the problems of insufficient lifting amount of gangue filling system, and achieve the effect of improving the dynamic transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

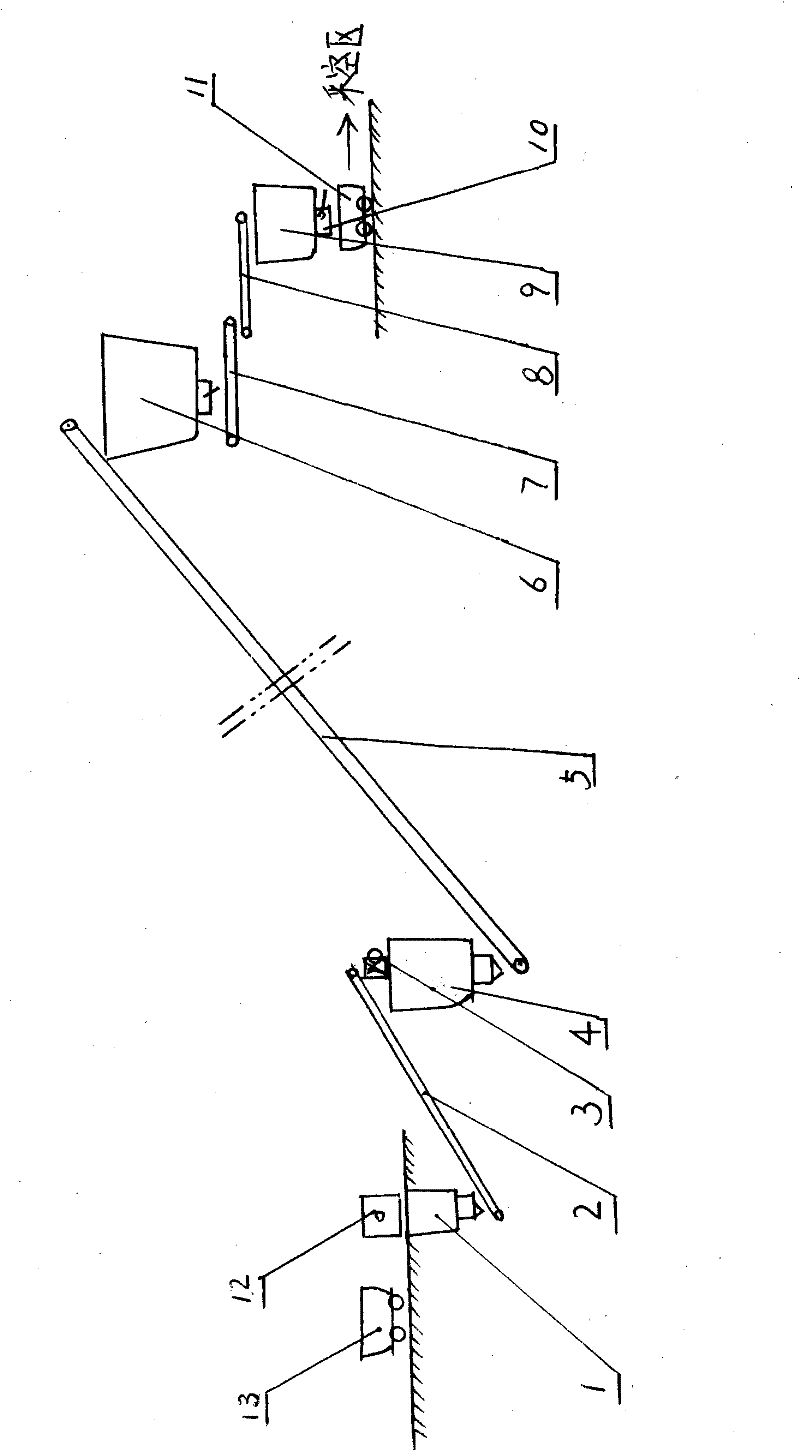

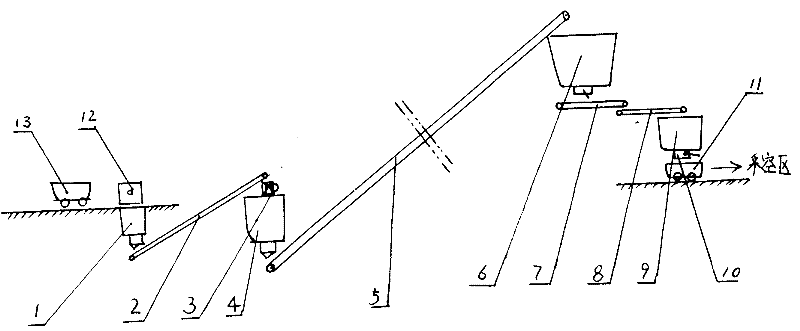

[0010] Those skilled in the art can implement according to the technical scheme and the accompanying drawings. Next, according to the attached figure 1 The gangue transportation process is described, so as to better understand the content of the present invention.

[0011] The gangue mine car 13 coming from the excavation face is unloaded into the gangue unloading pit 1 through the gangue unloading device 12 (such as a cage), and then sent to the gangue crusher 3 through the scraper conveyor 2 for crushing, and the crushed gangue falls into the In the lower coal bunker 4, the broken gangue in the lower coal bunker 4 is lifted to the upper coal bunker 6 by the coal conveyor belt conveyor 5, and the coal feeder 7 is started to reverse, and then transported to the gangue bin 9 by the conveyor 8. The equipment 10 is loaded into the mine car 11 and sent to the goaf for filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com