Tea packaging machine

A packaging machine and packaging bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packaging efficiency and achieve the effect of improving processing efficiency and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

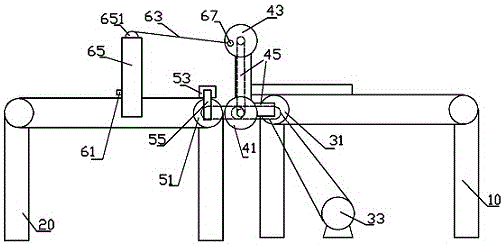

[0028] Such as figure 1 The tea packaging machine shown in the tea packaging machine includes a first support 10 and a second support 20 opposite to the first support 10;

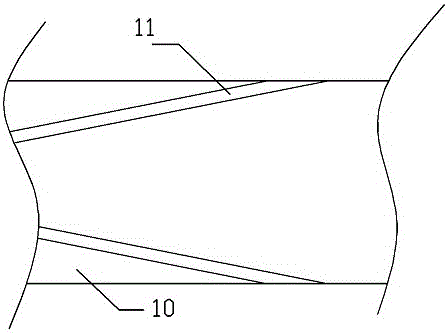

[0029] The first support 10 includes a first transport mechanism, a clamping mechanism for the packaging bag film and a connecting rod 45 connecting the clamping mechanism. The first two sides are provided with inclined fences 11;

[0030] The first transport mechanism includes a first driving roller 31 connected to the first support 10 at both ends, a first driven roller and a first transport belt between them, and the first driving roller 31 is connected with a motor 33 by a belt;

[0031] The clamping mechanism includes a first reel 41 and a second reel 43 wound with packaging bag film, the first reel 41 is connected with the driving roller through the horizontal section of the connecting rod 45, and the first reel 41 is connected with the first driving roller by a belt. The roller 31 is connected, the...

Embodiment 2

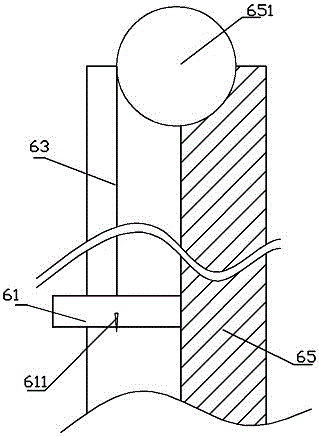

[0040] Different from Example 1, as Figure 4 As shown, in this embodiment, the upper end of the support rod 65 is provided with a through groove 652, and the lower end of the through groove 652 is an arc. The contact surface between the connecting piece 63 and the supporting rod 65 is increased by setting the through groove 652 whose lower end is a circular arc, thereby reducing the friction of the connecting piece 63 during sliding and prolonging the service life of the connecting piece 63 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com