Stone dumper for pile foundation filling

A technology of riprap boats and pile foundations, which is applied in the field of machine-installed throwing and filling in bridge construction. It can solve the problems of destroying the surface layer of pile foundations and pier abutments, affecting the direction of ships, and affecting structures, and achieves the effect of improving monitoring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

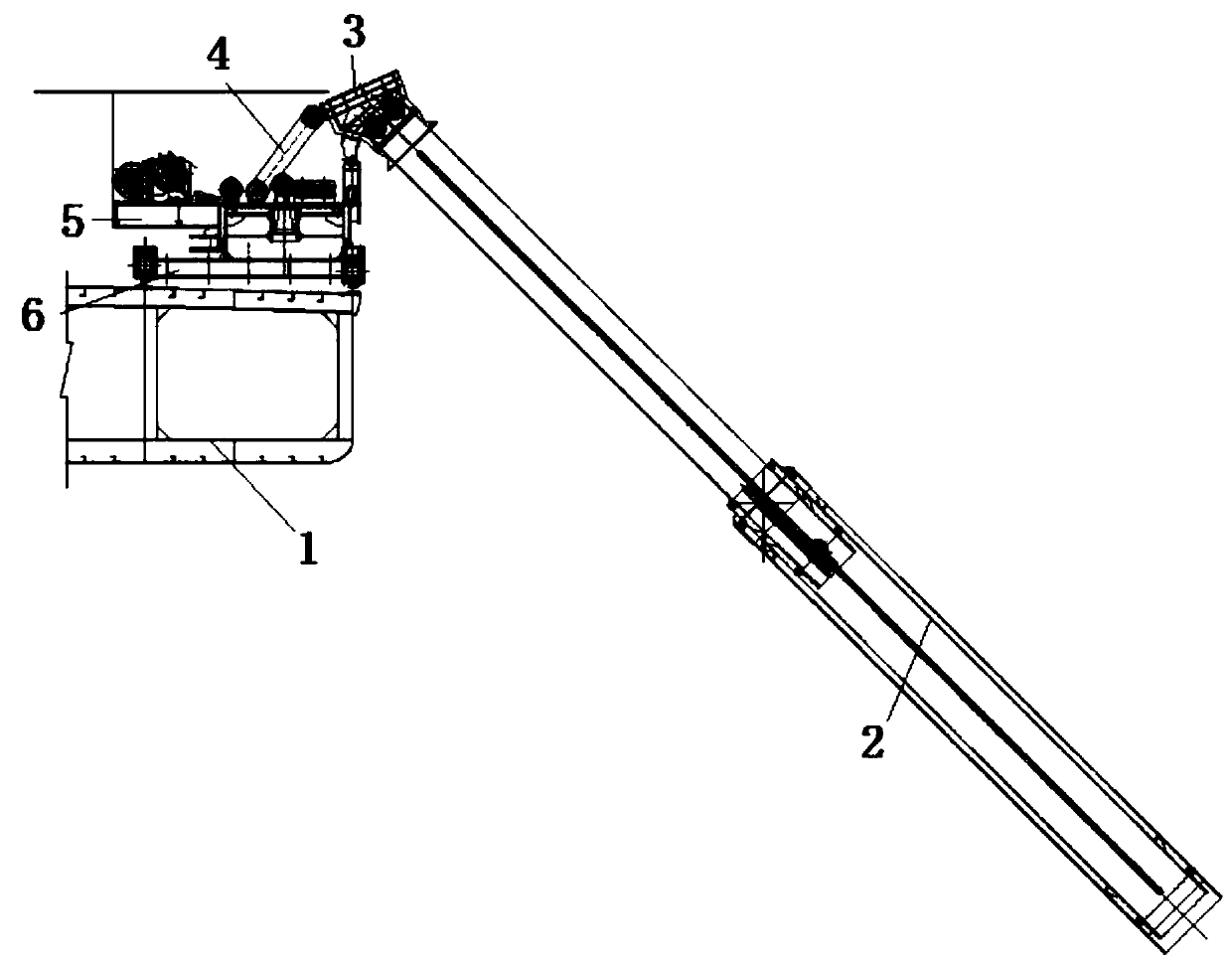

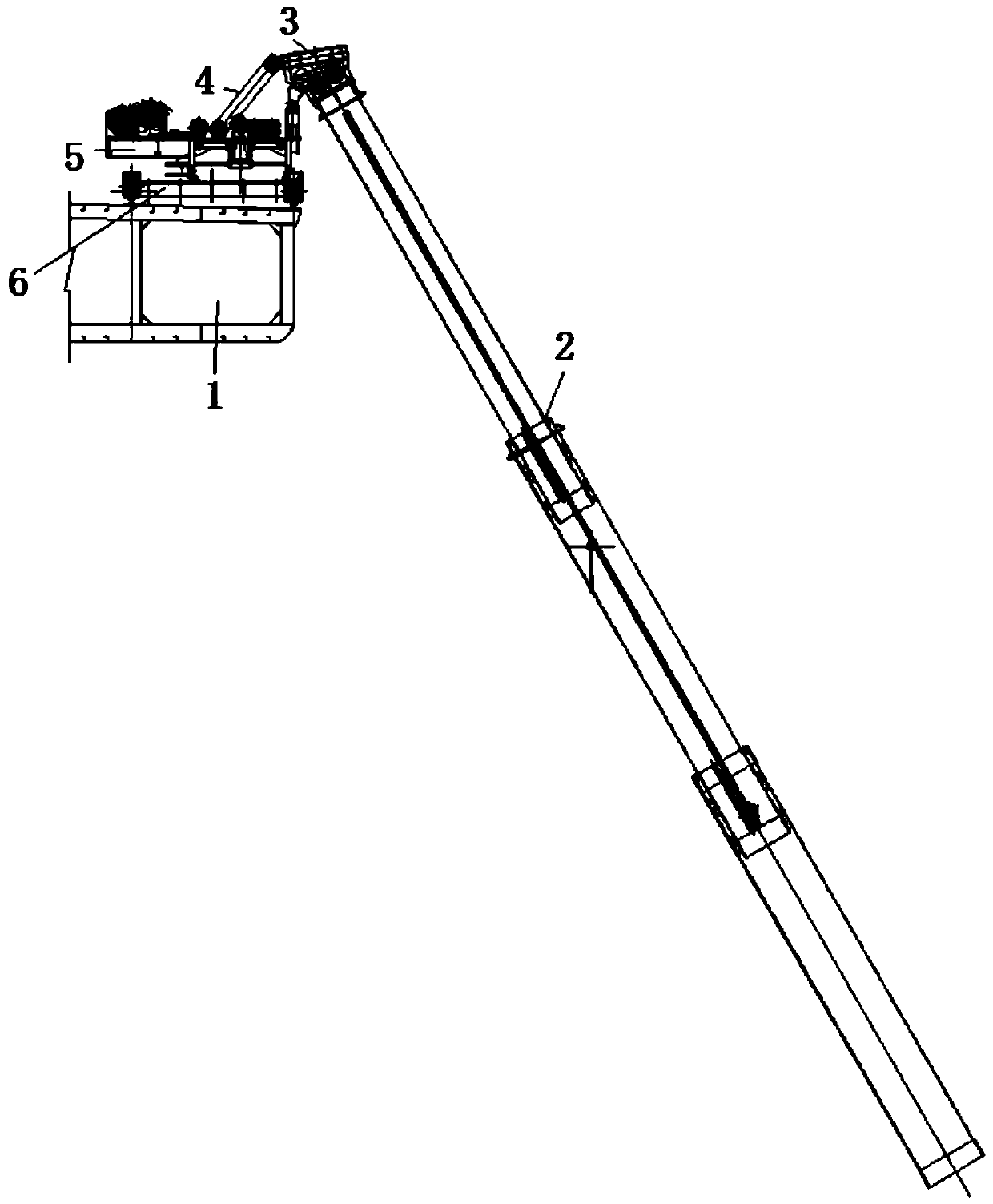

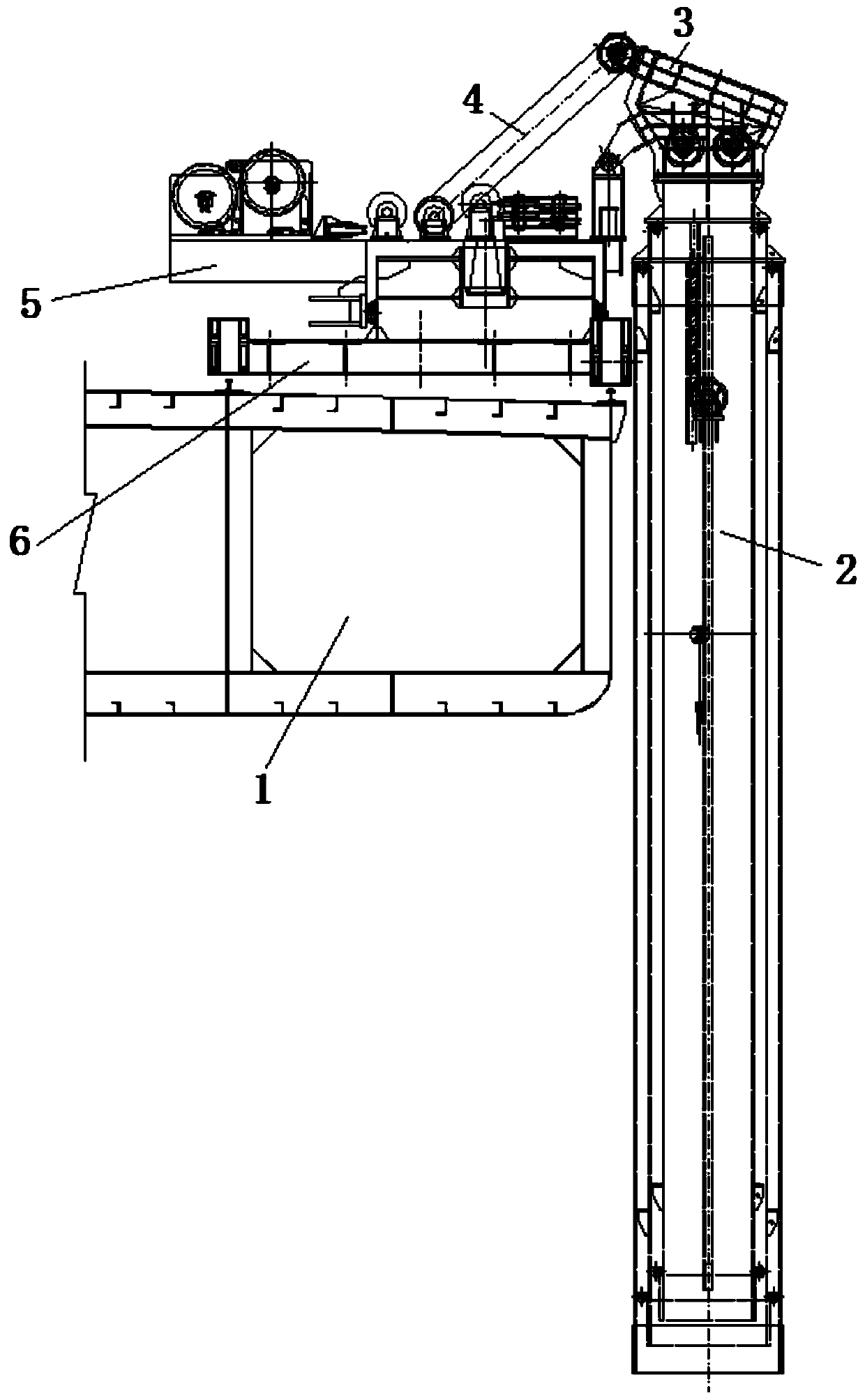

[0045] A kind of riprap boat that is used for pile foundation throwing and filling in the present embodiment, comprises hull 1, also comprises:

[0046] A chute 2, the chute 2 is arranged on the side of the hull 1, and the chute 2 is used for filling and throwing of the pile foundation;

[0047] A feed hopper 3, which is arranged on the top of the chute 2 and is used for feeding the chute 2;

[0048] Material conveying mechanism 4, the material conveying mechanism 4 is fixed on the deck of the hull 1, when filling and throwing, the material conveying mechanism 4 is used to convey the material to the chute 5, and realize the continuous feeding of the material;

[0049]The opening of the feeding hopper 3 faces upwards, the end of the material conveying mechanism 4 is arranged downward, and the feeding port 3 of the feeding hopper is arranged opposite to the end of the material conveying mechanism 4 .

[0050] In this technical solution, compared with the prior art, which uses t...

Embodiment 2

[0056] In this embodiment, the structure and adjustment of the chute are mainly introduced.

[0057] Refer to attached figure 1 As shown, it also includes a walking flat car 6 that can move along the window 1, and the walking flat car 6 is connected with the chute, and then the walking flat car 6 is controlled to realize the construction of the chute at different positions of the hull 1; a rotating platform is also provided 5. The rotating platform 5 is arranged on the upper part of the trolley 6, and the rotating platform 5 is used to realize the expansion and contraction of the chute 2, the vertical luffing and the adjustment of the left and right angles.

[0058] Compared with the prior art, by setting a turntable on the walking flat car, and then hinged the inclined chute, and by rotating the turntable and the walking flat car, throwing and filling at different positions is realized.

[0059] In this technical solution, specifically, the upper part of the chute is hinged ...

Embodiment 3

[0086] In this embodiment, the material conveying mechanism is mainly introduced.

[0087] Refer to attached Figure 5 As shown, the material conveying mechanism includes a hopper (not shown in the drawing) and a conveyor belt, and a safety distance is set between the hopper and the conveyor belt, and the safety distance is 0.6-1m.

[0088]The height of the receiving hopper is 0.7-1m. By setting the spacing, the sudden drop of bagged gravel can avoid damage to the conveyor belt. If the distance is less than 0.6m, the bagged gravel is easy to squeeze, which will lead to blockage at the receiving hopper; if the distance is greater than 1m, the gravel will fall, and it will easily damage the conveyor belt after long-term use.

[0089] The receiving hopper is made of steel, and the steel hopper is in the shape of a four-sided trumpet, with an opening on the starboard side elevation. The four corners are reinforced with channel steel, and diagonal braces are added to increase sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com