Wooden floorboard conveying device

A transportation device and floor technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as stability, poor reliability, poor stability, and falling, and achieve high safety, continuous transportation, and increased The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

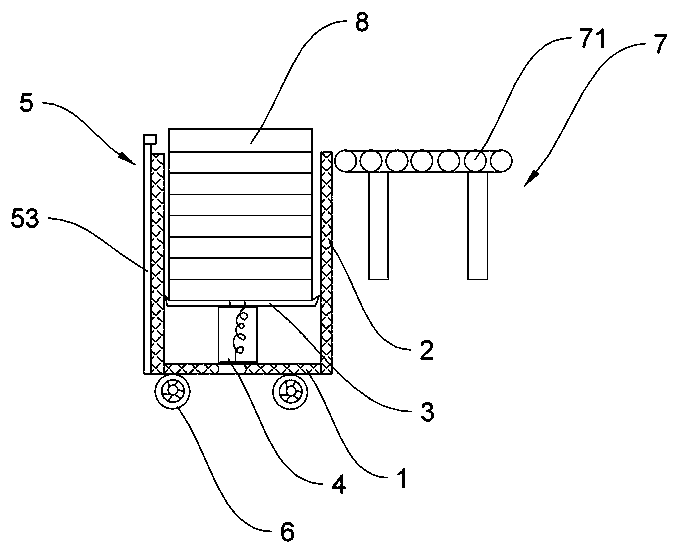

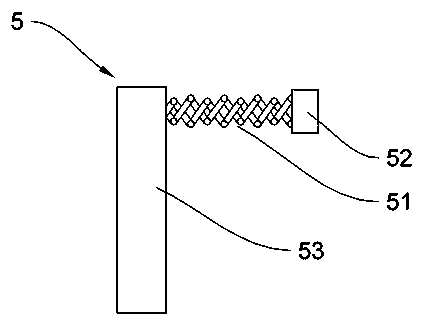

[0019] see figure 1 , figure 2 , a wooden floor transportation device, including a fixing mechanism, the fixing mechanism includes a telescopic bottom plate 1, auxiliary boards 2 arranged on both sides of the telescopic bottom plate 1 for limiting the floor 8, for placing the floor 8 A variable-area carrier 3, the carrier 3 is fixedly connected to the elastic member 4 fixed on the telescopic floor 1, and also includes a telescopic mechanism 5 for pushing the floor 8, the telescopic mechanism 5 includes a telescopic frame 51 and an elastic block 52 fixed at the end of the telescopic frame 51.

[0020] The working principle of this wooden floor transport device is as follows:

[0021] Adjust the area of the working area of the telescopic bottom plate 1 and the carrier 3 to adapt to the floor 8 to be transported, place the floor 8 on the carrier 3, and the elastic me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com