Technology of saving water and controlling aerosol phenomenon in ammonia desulphurization technology

An ammonia desulfurization and aerosol technology, applied in the field of ammonia desulfurization flue gas, can solve the problems of large floor space, low desulfurization efficiency, complex equipment, etc., and achieve the effects of low operating cost, good cooling effect, and simple system process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

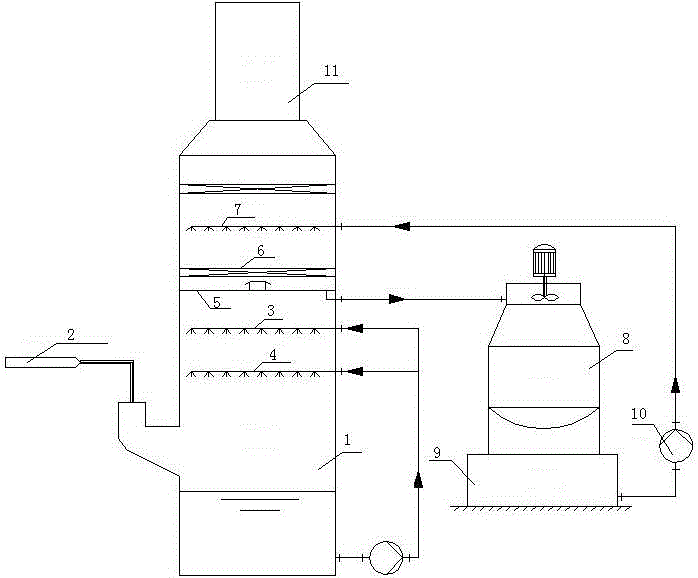

[0022] Such as figure 1 Shown, a kind of technology of saving water and controlling aerosol phenomenon in ammonia desulfurization process, comprises the following steps:

[0023] The first step: 120°C boiler flue gas enters the desulfurization tower 1 from the flue gas inlet 2 on the side of the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area is arranged in the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area There is a slurry spray layer inside, and the slurry spray layer is divided into an upper spray layer 3 and a lower spray layer 4, and the spray liquid and the SO contained in the desulfurization tower 2 The flue gas is sprayed, and the spray liquid uses ammonium sulfate / ammonium sulfite solution with a concentration of 5% m / m, and 95% of SO in the flue gas 2 It is captured in the flue gas cooling concentration and sulfur dioxide absorption area, and the temperature of th...

Embodiment 2

[0028] Such as figure 1 Shown, a kind of technology of saving water and controlling aerosol phenomenon in ammonia desulfurization process, comprises the following steps:

[0029] The first step: 130°C boiler flue gas enters the desulfurization tower 1 from the flue gas inlet 2 on the side of the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area is arranged in the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area There is a slurry spray layer inside, and the slurry spray layer is divided into an upper spray layer 3 and a lower spray layer 4, and the spray liquid and the SO contained in the desulfurization tower 2 The flue gas is sprayed, and the spray liquid uses ammonium sulfate / ammonium sulfite solution with a concentration of 35% m / m, and 99% of SO in the flue gas 2 It is captured in the flue gas cooling concentration and sulfur dioxide absorption area, and the temperature of t...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of technology of saving water and controlling aerosol phenomenon in ammonia desulfurization process, comprises the following steps:

[0035] The first step: 140°C boiler flue gas enters the desulfurization tower 1 from the flue gas inlet 2 on the side of the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area is arranged in the desulfurization tower 1, and the flue gas cooling concentration and sulfur dioxide absorption area There is a slurry spray layer inside, and the slurry spray layer is divided into an upper spray layer 3 and a lower spray layer 4, and the spray liquid and the SO contained in the desulfurization tower 2 The flue gas is sprayed, and the spray liquid uses ammonium sulfate / ammonium sulfite solution with a concentration of 10% m / m, and 96% of SO in the flue gas 2 It is captured in the flue gas cooling concentration and sulfur dioxide absorption area, and the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com