Solid oxide fuel cell system and solid oxide fuel cell power generation method

A fuel cell system and solid oxide technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of large power consumption and low single-pass conversion rate, improve power generation efficiency, and simplify the system process. , The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

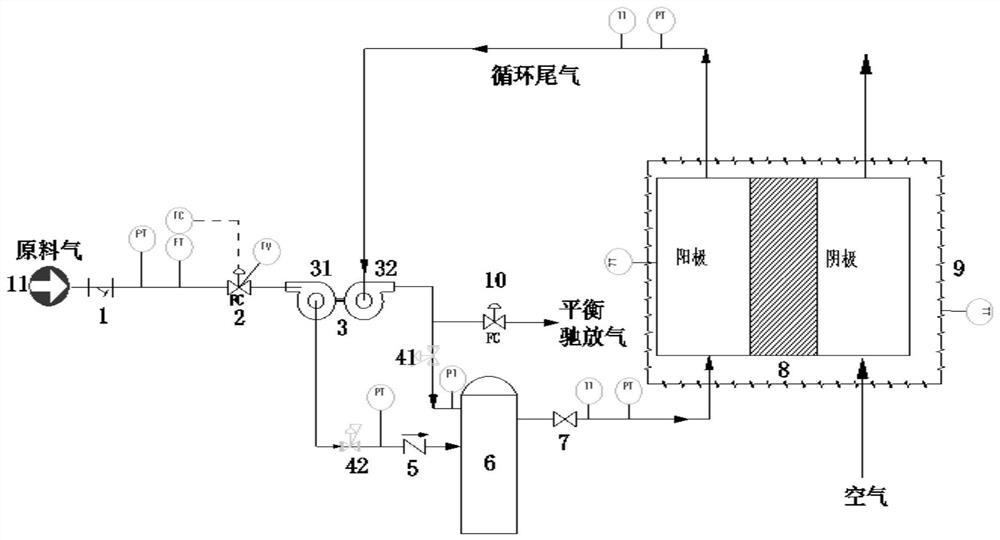

Embodiment 1

[0090] This embodiment operates under the condition that the power generation capacity of the electric stack is 1kW. The specific operation process includes:

[0091] Synthesis gas from feed gas source 11 (specifically including: N 2 1.12% by volume, O 2 0.02% by volume, H 2 61.78vol%, CO 36.71vol%, CO 2 0.24% by volume and CH 4 0.13 volume %) enters in the turbine 31 of turbocharging device 3 after passing through filter 1 and flow meter 2 successively, and the temperature, pressure and flow of feed gas are measured at the inlet of this turbine 31, and are recorded in Table 1. The feed gas drives the turbine 31 to rotate, thereby driving the coaxial impeller 32 to also rotate. The rotation of the impeller 32 generates negative pressure to suck the anode tail gas generated by the electric stack 8 . The raw gas passing through the turbine 31 enters the mixing tank 6 after passing through the anode tail gas pressure regulating valve 41 and the one-way valve 5 successiv...

Embodiment 2

[0098] This embodiment is carried out under the condition that the generating capacity of the electric stack is 4kW, and the specific operation process is carried out according to the embodiment 1.

[0099] The specific operating parameters are shown in Table 2.

[0100] After testing and calculation,

[0101] The power generation efficiency of the system is 55.8%;

[0102] The emission rate of pollutant gas in the exhaust gas (gas that undergoes balance relaxation at the balance valve 10 ) was 14.1% by volume.

[0103] Table 2

[0104]

Embodiment 3

[0106] According to the method of Example 1, the difference is that the balance valve 10 is used to adjust the amount of anode tail gas that is balanced and relaxed, so that the operating parameters are as shown in Table 3.

[0107] After testing and calculation,

[0108] The power generation efficiency of the system is 55.4%;

[0109] The emission rate of pollutant gas in the exhaust gas (gas that undergoes balance relaxation at the balance valve 10 ) was 14.5% by volume.

[0110] table 3

[0111]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com