Anhydration and incineration processing method for wet sludge

A treatment method and wet sludge technology, applied in combustion methods, dewatering/drying/concentrating sludge treatment, incinerators, etc., can solve the problem of difficulty in ensuring high temperature removal of harmful substances in sludge, no disclosure of dryer exhaust gas, It cannot guarantee the harmlessness of exhaust gas and other problems, so as to achieve the effect of low initial investment of equipment, high operation stability and reliability, and reduced operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

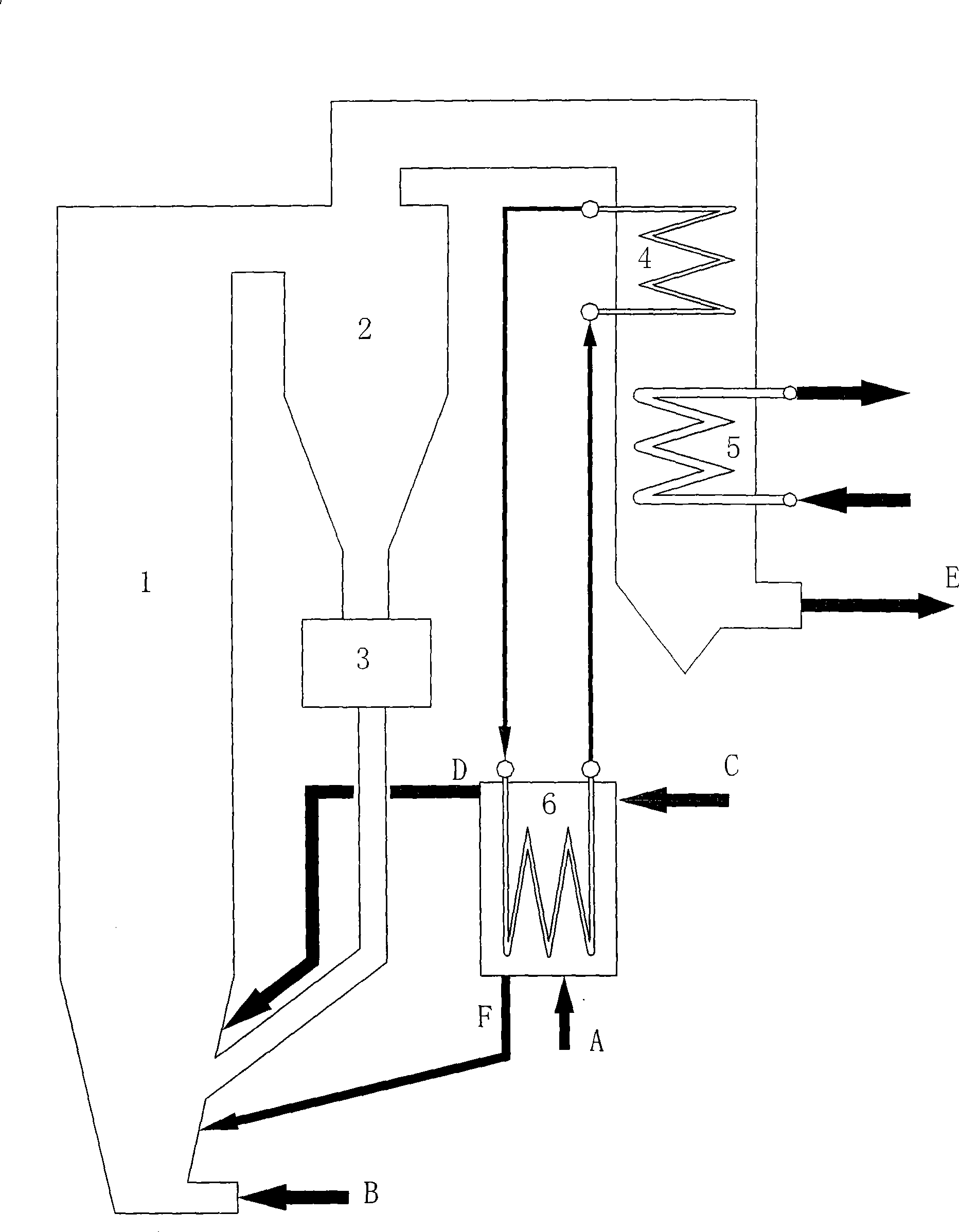

[0041] see figure 1 :

[0042] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 6, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas E is cooled by the heat exchanger 4 and the air preheater 5 in the tail flue, and after the dust is removed by the dust collector, it is discharged through the chimney.

[0043] The wet sludge C that has been broken up is added from the upper part of the sludge dryer 6, and is used as the hot air fluidization of the fluidizing gas A of the sludge dryer, and at the same time absorbs the release of the heat release coil in the sludge dryer 6 The heat is dried to the dry sludge F with a moisture content of 5%, discharged from the bottom of the sludge dryer 6, sent to the furnace 1, and incinerated at 850°C. The generated flue gas E is separated ...

Embodiment 2

[0048] see figure 1 :

[0049] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 60% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 6, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas E is cooled by the heat exchanger 4 and the air preheater 5 in the tail flue, and after the dust is removed by the dust collector, it is discharged through the chimney.

[0050] The wet sludge C that has been broken up is added from the upper part of the sludge dryer 6, and is used as the hot air fluidization of the fluidizing gas A of the sludge dryer, and at the same time absorbs the release of the heat release coil in the sludge dryer 6 The heat is dried to dry sludge F with a moisture content of 10%, discharged from the bottom of the sludge dryer 6, sent to the furnace 1, and incinerated at 900°C. The generated flue gas E is separated fro...

Embodiment 3

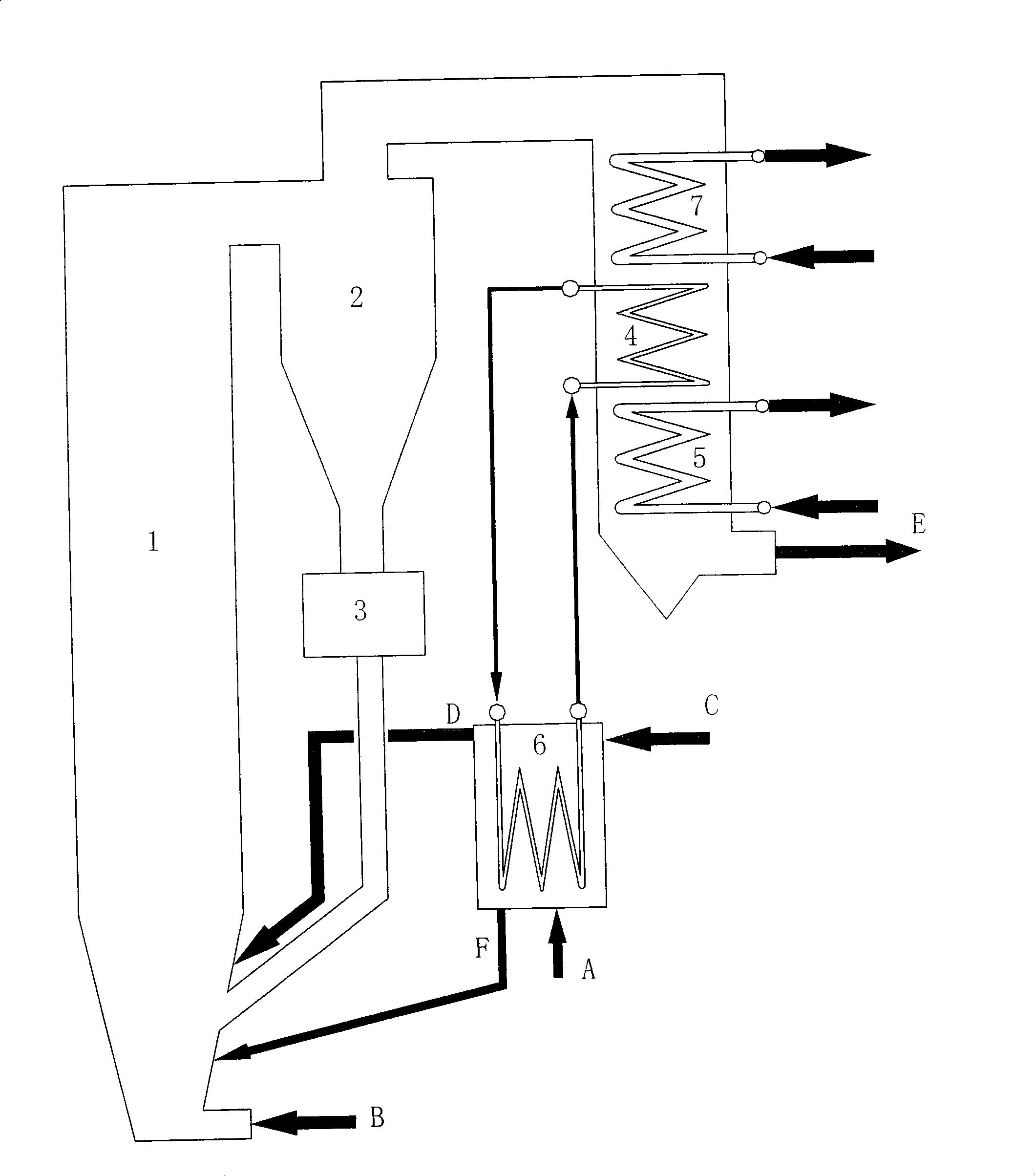

[0055] see figure 2 :

[0056] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3500kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 6, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas E is cooled by the heat exchanger 4, the air preheater 5 and the waste heat boiler 7 in the tail flue, and is discharged through the chimney after being dedusted by the dust collector.

[0057] The wet sludge C that has been broken up is added from the upper part of the sludge dryer 6, and is used as the hot air fluidization of the fluidizing gas A of the sludge dryer, and at the same time absorbs the release of the heat release coil in the sludge dryer 6 The heat is dried to dry sludge F with a moisture content of 25%, discharged from the bottom of the sludge dryer 6, sent to the furnace 1, and incinerated at 860°C. The generated flue gas E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com