Wet sludge drying, incinerating and treating device

A treatment device and wet sludge technology, applied in the field of waste treatment devices, can solve problems such as heat waste, and achieve the effects of reducing consumption, reducing operating costs, and simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

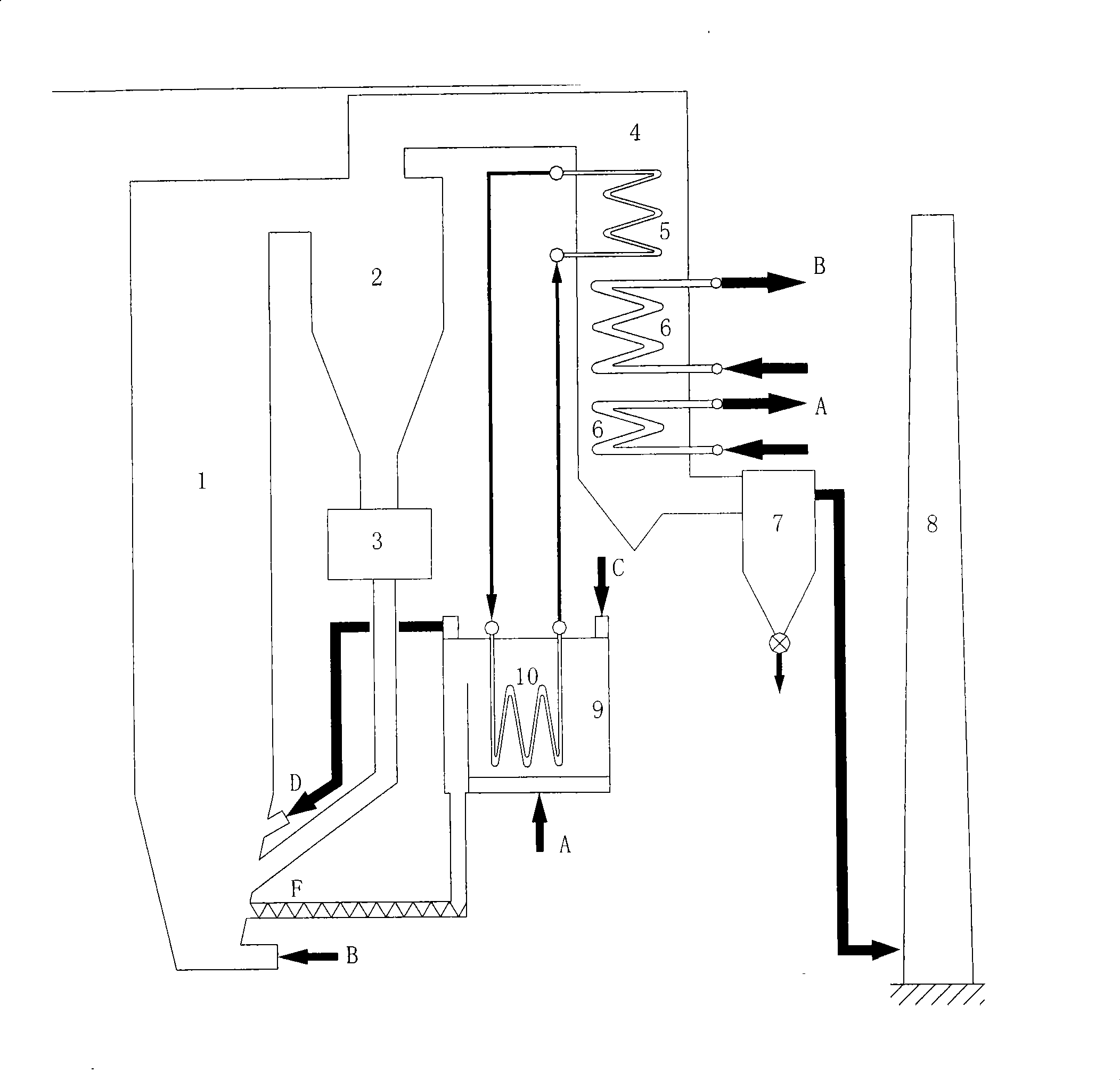

[0038] see figure 1 :

[0039] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5 and the air preheater 6 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0040] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0041] The furnace 1 is insulated, and the side wall is provided with a secondary tuyere, a feeding port, and a dry sludge inlet.

[0042] The sludge dryer 9 is a fluidized bed type, with a wind cap and an air distribution plate at the ...

Embodiment 2

[0051] see figure 1 :

[0052] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 60% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5 and the air preheater 6 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0053] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0054] A water-cooled heating surface is provided in the furnace 1, and its side wall is a membrane water-cooled wall, and the lower part of the side wall is provided with a secondary tuyere, a feeding port, and a dry sludge inlet.

[0...

Embodiment 3

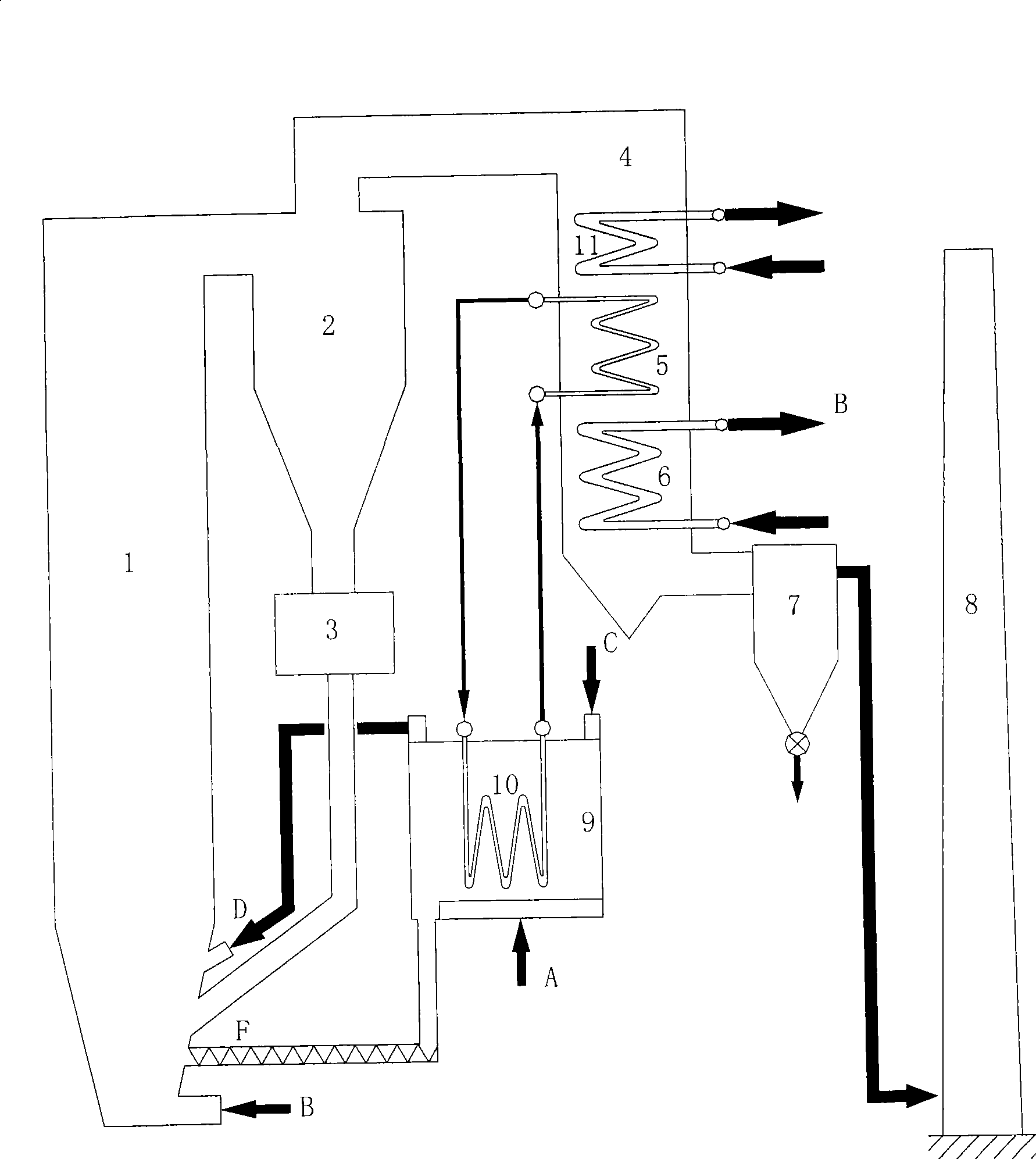

[0063] see figure 2 :

[0064] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3500kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5, the air preheater 6 and the waste heat boiler 11 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0065] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0066] The furnace 1 is insulated, and the lower part of the side wall is provided with a secondary tuyere, a material return port and a dry sludge inlet.

[0067] The sludge dryer 9 is a fluidized bed type, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com