Industrial wastewater treatment method using bladder-type anaerobic pond

A technology of industrial sewage and treatment methods, which is applied in the direction of aerobic and anaerobic process treatment, can solve the problems of large manpower and building materials, small single tank volume, and cost, and achieve the reduction of excess sludge, simplified system process, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

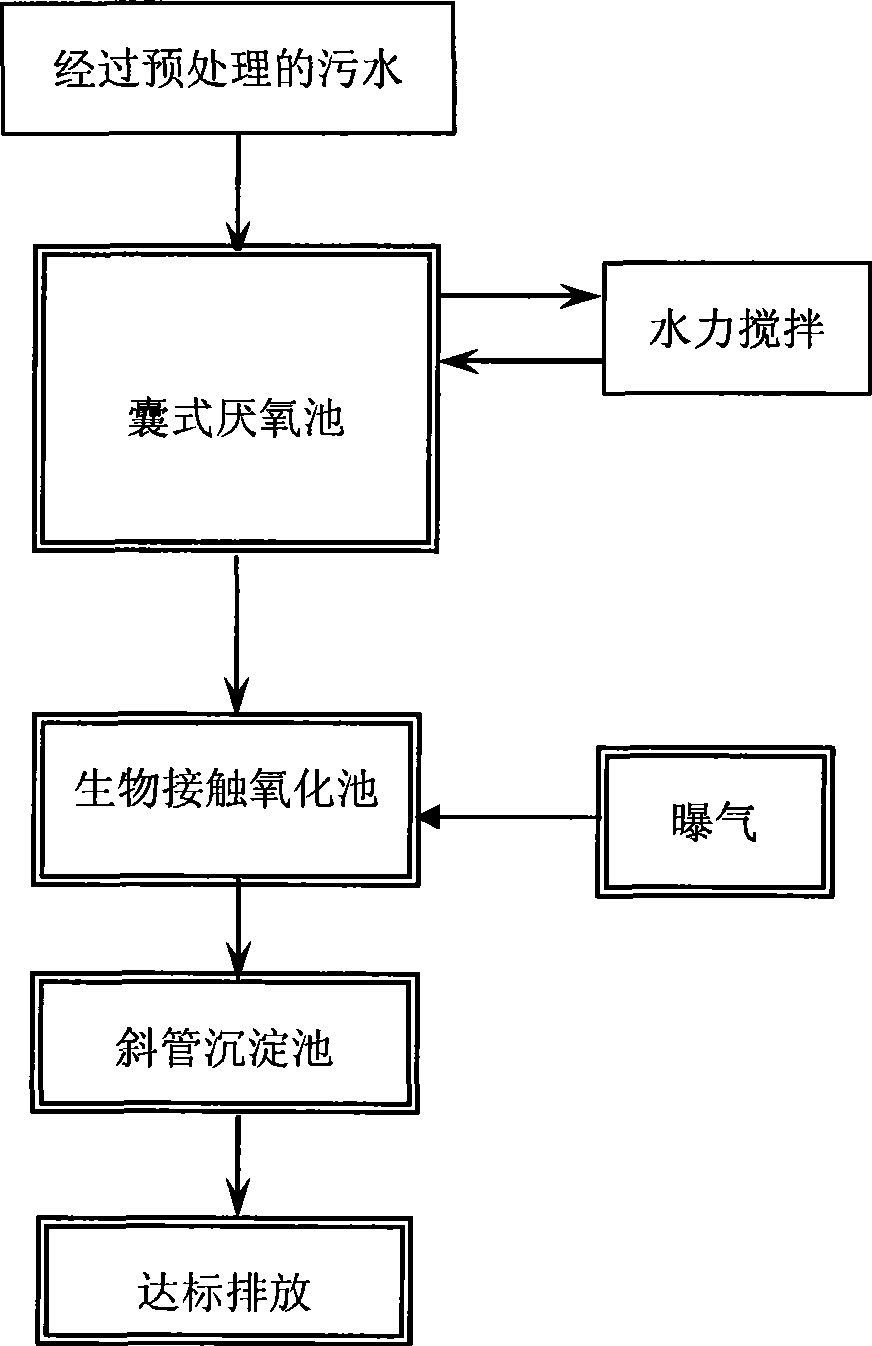

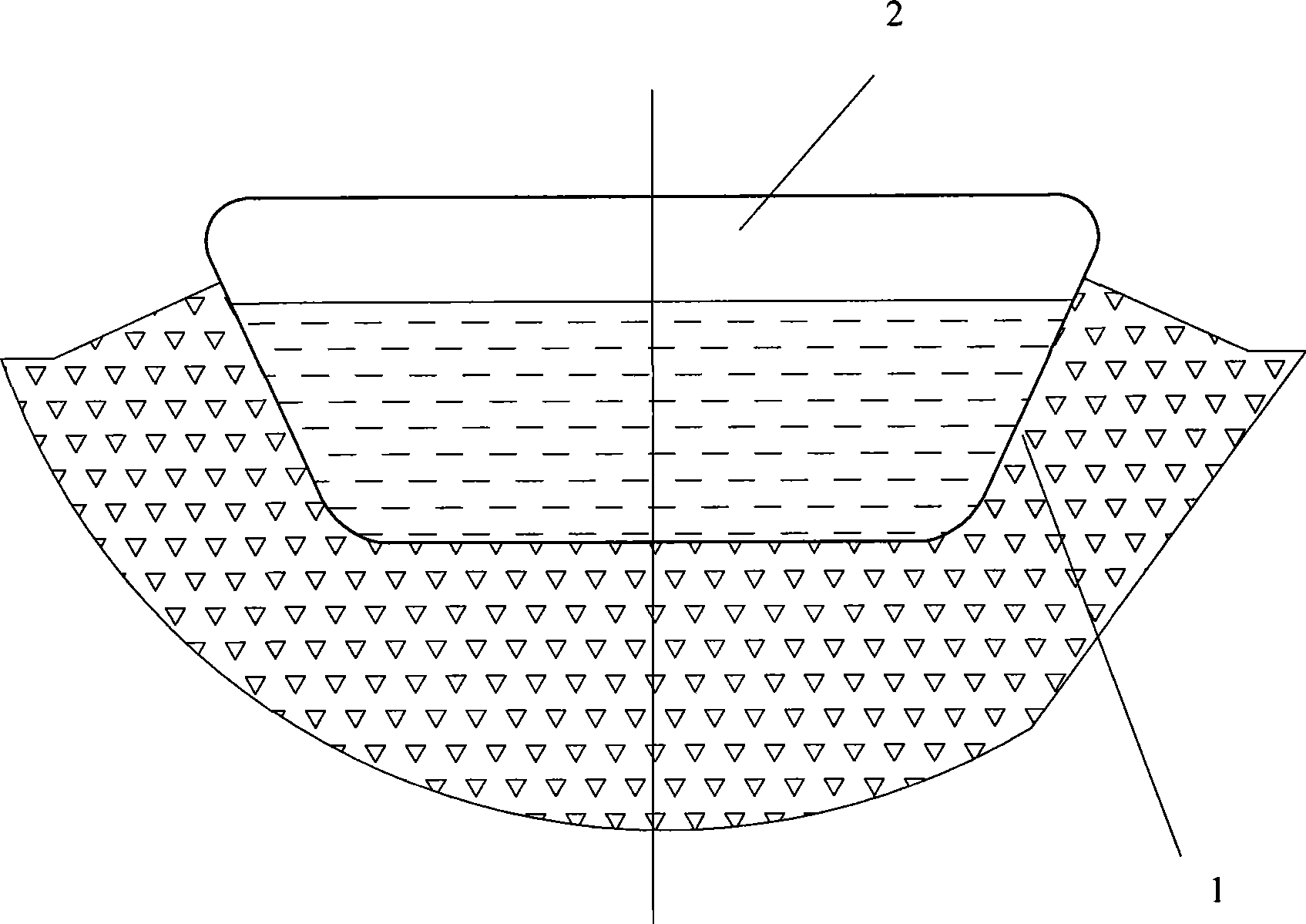

[0017] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. This embodiment is realized through the following steps: a. Discharge the pretreated sewage into the capsule anaerobic tank, and the sewage is fully contacted and adsorbed with the return sludge from the end of the capsule anaerobic tank through jet agitation, and the anaerobic tank is anaerobic. Oxygen reaction; the capsule anaerobic tank is a water capsule made of high-strength HDPE plastic film, and acid-producing bacteria and methanogenic bacteria are symbiotic in the water capsule; b, the sewage treated in step a carries out aerobic reaction, For example, enter the biological contact oxidation tank, further remove the remaining organic matter in the water, and use a fan to aerate the biological contact oxidation tank; c, the sewage treated in step b enters the inclined tube sedimentation tank, and separates the mud and water; d, passes...

specific Embodiment approach 3

[0022] Specific implementation method three: high-efficiency jet hydraulic agitation is carried out in the first third of the capsule anaerobic tank in step a, and a sludge return device is installed in the second third of the part to evenly return the settled sludge to the front section Re-engage the response. Others are the same as the first embodiment.

specific Embodiment approach 4

[0023] Specific embodiment four: In this embodiment, the biological contact oxidation tank in step b adopts blast aeration. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com