Resource technology and system for separating salt from high-salinity wastewater

A high-salt wastewater and process technology, which is applied in the field of high-salt wastewater and salt separation, can solve the problems of reducing solid waste, low recovery rate of crystallized salt, and large amount of foreign salt, so as to solve the problem of poor effluent effect , reduce scaling and pollution problems, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

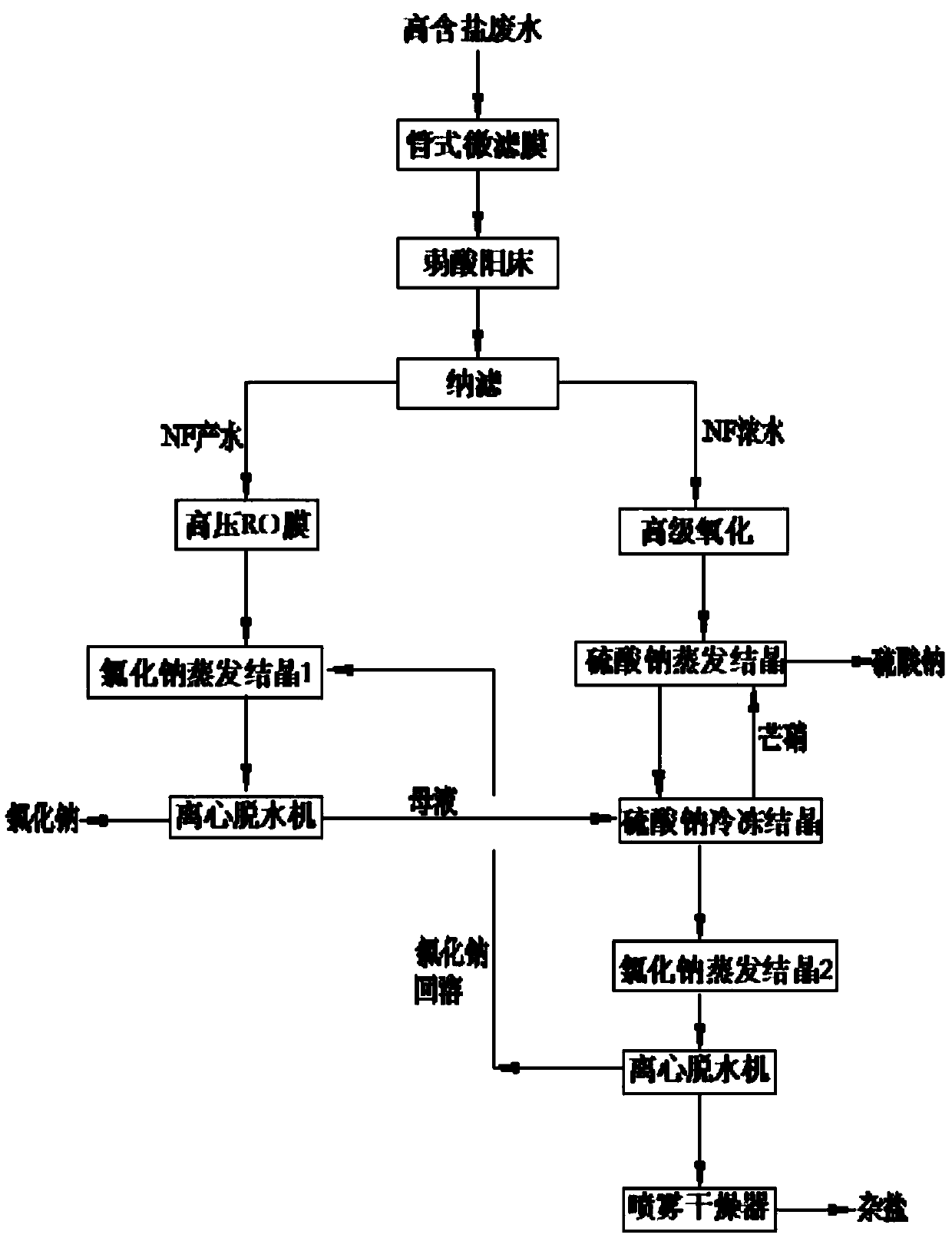

[0043] Please refer to the attached figure 1 , which shows the main process steps and used equipment systems of the present invention.

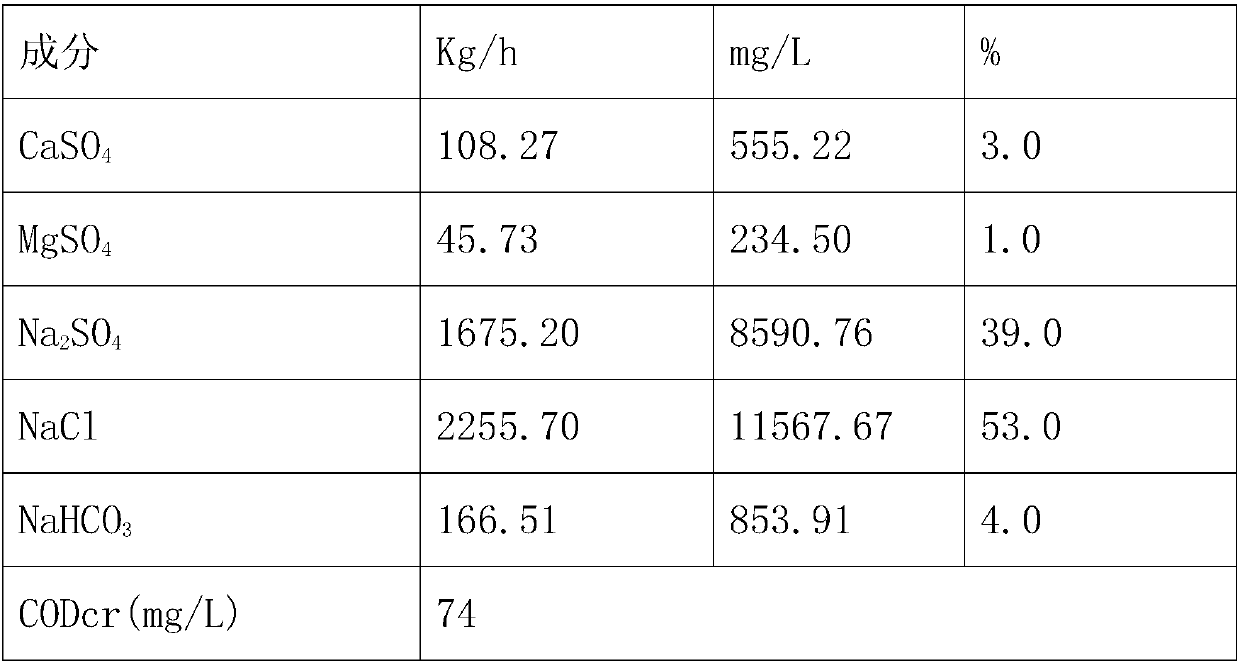

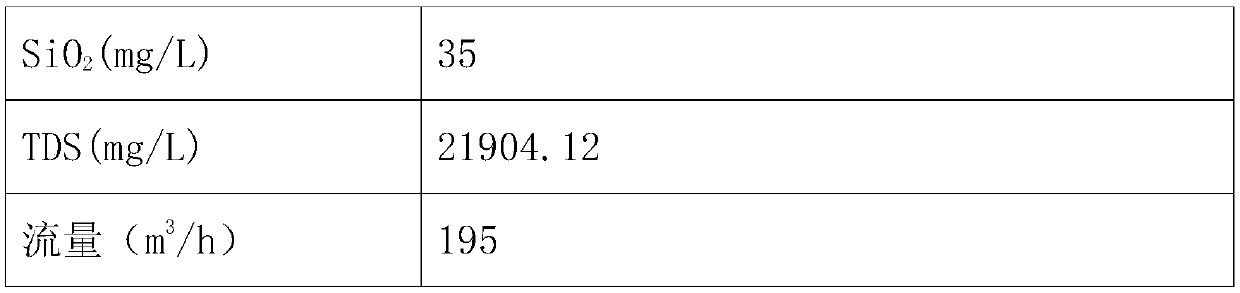

[0044] In the specific embodiment of the present invention, the hardness, alkalinity, silicon, fluorine ion and suspended solids of wastewater are reduced or removed through the pretreatment system (including tubular microfiltration system, weak acid resin hard removal system), ensuring that the nanofiltration system Stable operation, while improving the purity of crystallized salt produced by the subsequent system. Through the preliminary salt separation of nanofiltration, the product water side is mainly sodium chloride, and NaCl with a purity of not less than 98.5% is obtained through membrane concentration and evaporation crystallization. Preliminary salt separation through nanofiltration, after the concentrated water of nanofiltration removes most of the organic matter through the advanced oxidation system, sodium sulfate is produced th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com