A medium and high pressure solid polymer water electrolysis device

A solid polymer, water electrolysis technology, applied in electrolysis process, electrolysis components, chemical industry, etc., can solve the problems of unsuitable medium and high voltage operation, difficult maintenance, complex system, etc., to achieve improved safety, simple and simplified system process The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

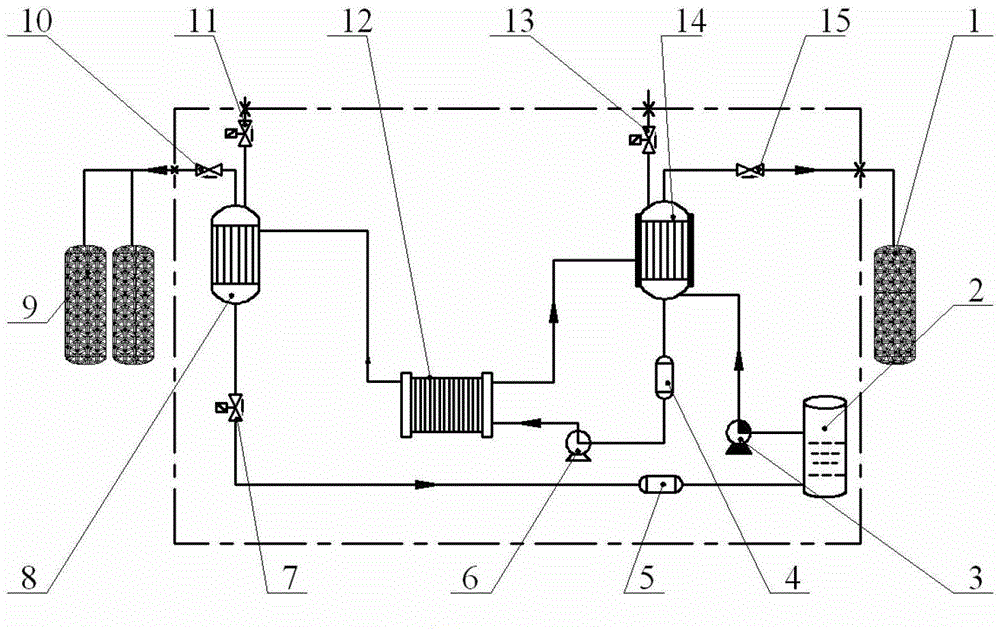

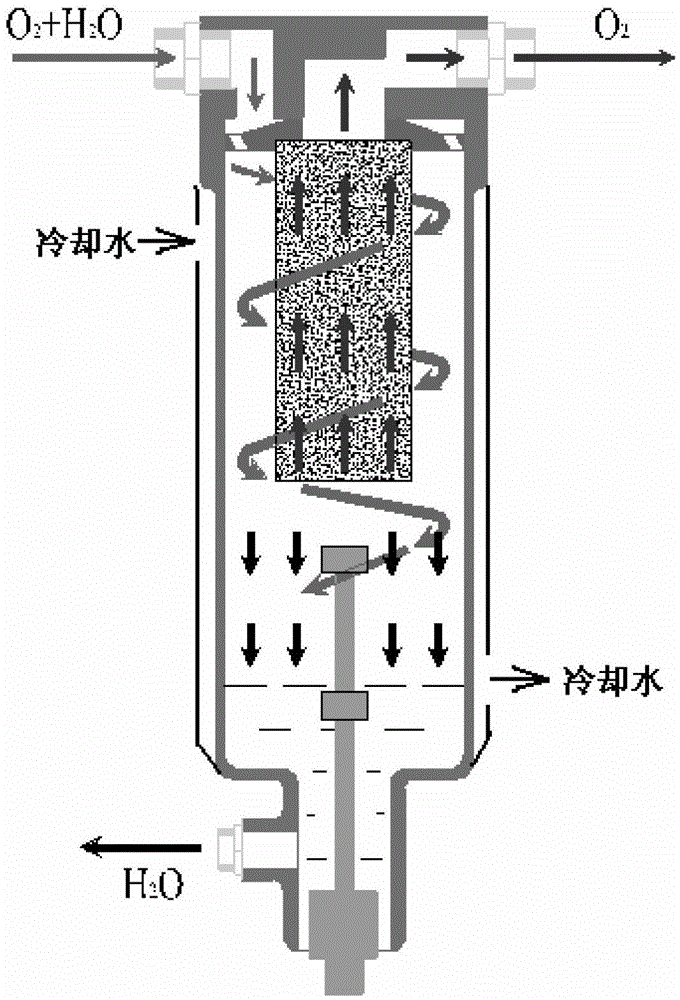

[0035] Such as figure 1As shown, it is a schematic flow diagram of the medium and high pressure solid polymer electrolyte water electrolysis system of the present invention, which is composed of an electrolytic cell stack, a gas separation and management process, a water supply and management process, and a cooling part process. The electrolytic cell stack adopts the water supply mode on the anode side, and the structure of the anode water separator is as follows: figure 2 As shown, there is a water-cooling jacket on the outside, so as to have the triple functions of the gas-water separator, the anode water supply tank, and the radiator. This embodiment is especially suitable for small systems, and does not require additional heat dissipation equipment. In this embodiment, the hydrogen production capacity is 1Nm 3 / h, the specific process is as follows.

[0036] The pure water stored in the lower part of the water separator 14 on the anode side is injected into the anode o...

Embodiment 2

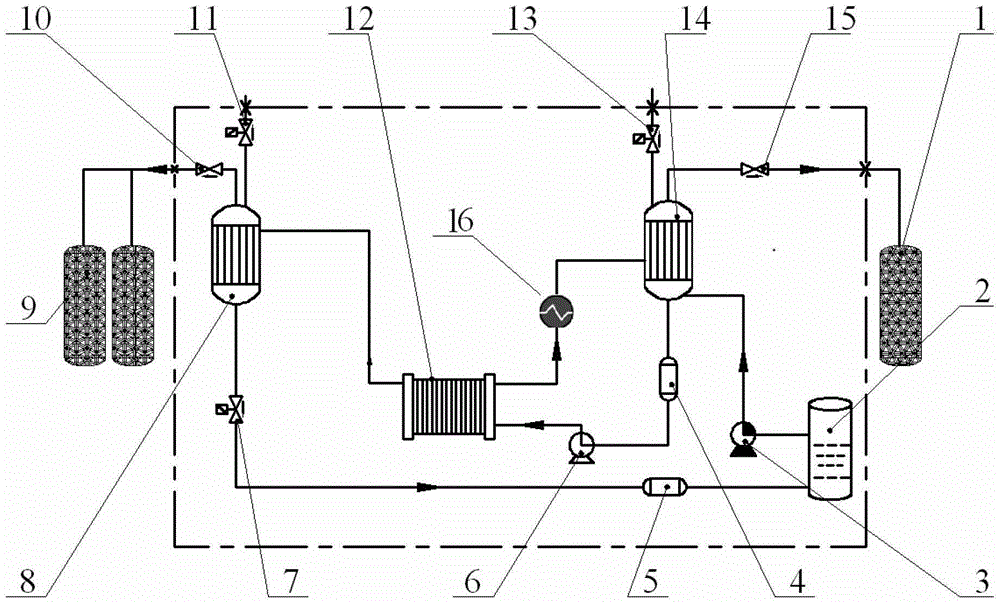

[0040] image 3 SPE water electrolysis system flow chart, the main components are in figure 1 The anode side radiator 16 is added on the basis of the above, and this embodiment is especially suitable for large-scale systems.

[0041] The anode-side radiator 16 is arranged on the pipeline between the anode-side water-gas outlet of the electrolytic cell stack 12 and the water-gas inlet of the anode-side gas-water separator 14 .

[0042] The invention has simple process and high system efficiency, and is suitable for various occasions where high-purity hydrogen and high-purity oxygen are required, especially the occasions where medium-high pressure high-purity hydrogen and high-purity oxygen are required, such as cooling medium for large-scale thermal power generation units, and silicon single products in the semiconductor industry Prepared protective gas, and high-efficiency energy storage, etc. The invention can be combined with the fuel cell to form a renewable fuel cell sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com