Gas boiler smoke discharge device and process

A technology for gas boilers and emission devices, which is applied to combined devices, gas treatment, membrane technology, etc., can solve the problems of difficult emission control and inability to control dust emission, and achieve the effect of ultra-low concentration emission and efficient and deep removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with each accompanying drawing, the present invention is described in detail.

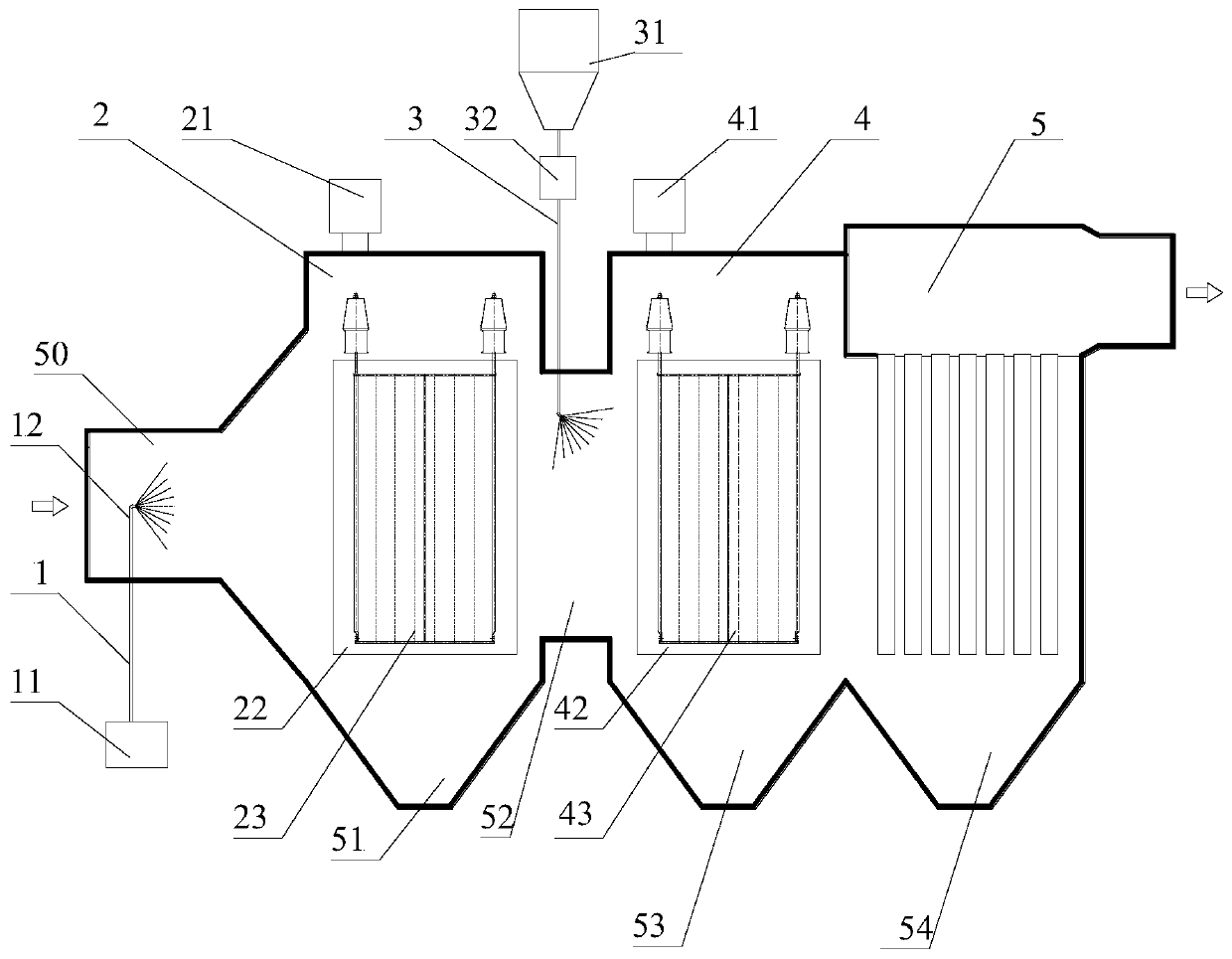

[0030] figure 1 It is a structural schematic diagram of the gas boiler flue gas discharge device of the present invention. Such as figure 1 As shown, the present invention provides a discharge device for flue gas from a gas boiler, which includes a treatment channel, and the treatment channel is sequentially provided with an ammonia water nozzle 1, a low-temperature plasma reaction unit 2, a dry powder nozzle 3, a dry Electrostatic precipitator unit 4 and bag dedusting unit 5; The outlet end of ammonia water spray pipe 1 is equipped with two-fluid atomizing spray gun 12, and discharge device also includes ammonia water supply system 11, and ammonia water supply system 11 is connected with ammonia water spray pipe 1, is used for supplying ammonia water Nozzle supplies ammonia; the outlet end of the dry powder nozzle 3 is equipped with a nozzle, and the discharge device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com